- 416 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Carpentry and Joinery 3

About this book

Carpentry and Joinery 3 is the third in a series of three books, which together provide an authoritative and thoroughly practical guide to carpentry and joinery for students following City & Guilds and CITB courses, NVQ candidates, and students working towards an Institute of Carpenters qualification. This book is also ideal for a wide range of amateur and professional woodworkers. Volume 3 builds on the fundamental knowledge introduced in volume 1, and accompanies volume 2 with coverage of additional advanced topics and procedures, including working with particular door and window types. The reader is shown how to apply the basic theory introduced in volume 1 to actual carpentry and joinery practice in a highly illustrated, easily accessible text.This second edition has been fully updated in line with changes to the Building Regulations and current legislation, the third edition also incorporates developments in current best practice, with a comprehensive match to the latest qualifications in Wood Occupations.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

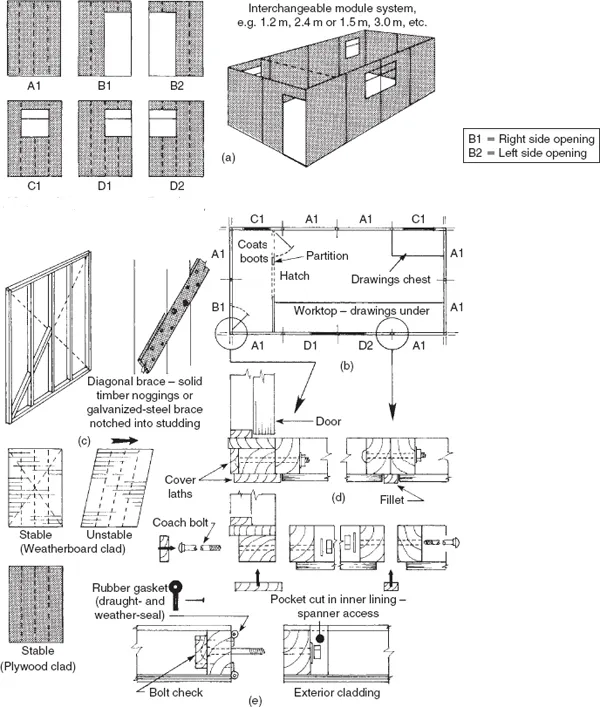

| 1 | Prefabricated Buildings |

Site hut (see Fig. 1.1) – wall panels 1.2 m (type 600 module)

| Panel code | Number |

| A1 | 7 |

| B1 | 1 |

| B2 | 0 |

| C1 | 2 |

| D1 | 1 |

| D1 | 1 |

| Total number of panels | 12 |

- the type of building;

- the size and type of cladding;

- transportation;

- handling techniques, for example, by hand or machine.

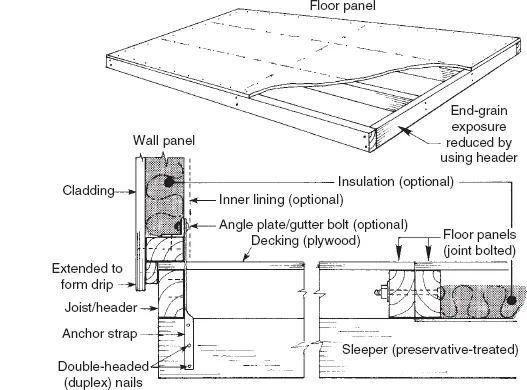

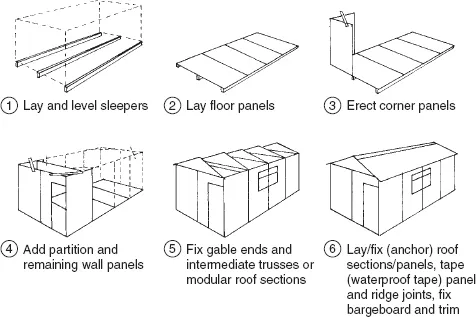

- Lay and level heavy-sectioned sleepers (bearers). Wood-preservative treatment is essential. (See also Volume 1, Chapter 3.)

- Lay and connect (using coach bolts) an appropriate number of floor ...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright

- Contents

- Foreword

- Foreword

- Preface

- Acknowledgements

- Chapter One: Prefabricated Buildings

- Chapter Two: External Cladding

- Chapter Three: Windows

- Chapter Four: Domestic Doors, Frames and Linings

- Chapter Five: Domestic Garage Doors

- Chapter Six: Domestic Gates

- Chapter Seven: Stairs

- Chapter Eight: Wood Wall Trims and Finishes

- Chapter Nine: Casing-In and Wall Panelling

- Chapter Ten: Joinery Fitments and Purpose – Made Joinery

- Chapter Eleven: Shoring Buildings

- Chapter Twelve: Repairs and Maintenance

- Volumes and Chapters

- Index

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app