eBook - ePub

Toyota by Toyota

Reflections from the Inside Leaders on the Techniques That Revolutionized the Industry

- 240 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Toyota by Toyota

Reflections from the Inside Leaders on the Techniques That Revolutionized the Industry

About this book

Written by former Toyota associates, Toyota By Toyota: Reflections from the Inside Leaders on the Techniques That Revolutionized the Industry focuses on the purpose of Lean methodologies, techniques, and principles. It compiles more than a century of combined experience from management-level employees who supply little-known insights about the Toyo

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Courage, Humility, Kaizen

Darril Wilburn

I consider myself one of the luckiest people to have worked at Toyota. Everyone who works at Toyota receives invaluable training and on-the-job development, and I was no exception. What made me so lucky was the chance to work at three locations as well as being involved in high-profile projects. I had the opportunity to work at Toyota Motor Manufacturing Kentucky, the largest plant in North America; the North American corporate headquarters; and finally to be part of a new plant start-up team at Toyota Motor Manufacturing Texas. In addition, I worked on significant projects such as The Toyota Business Practice and The Toyota Way 2001. Most significant was the opportunity to be trained by Toyota’s internal TPS group, Operations Management Development Division (OMDD). I am forever grateful for the opportunities afforded me while at Toyota and thank all the wonderful teachers and leaders who did their best to teach me The Toyota Way.

With a background in education, process improvement, and leadership coaching, I was hired in the late 1990s as a Development Coach at the Kentucky plant. My job was to teach and coach members of the leadership team on how to improve their “people” skills. I was assigned several managers to meet with and develop strategies that would allow them to work with their people more productively. My typical manager was one who was quite good at the technical aspects of the job but had a more difficult time developing the type of relationship that fostered mutual trust, a key component in the Toyota Production System (TPS).

The position of Development Coach at the Kentucky plant was a new position and one that was established by my first Sensei. She believed strongly that Mutual Trust was a key in the development of a TPS culture. She also believed that we could develop people in leadership positions who did not naturally possess the skills needed to build mutual trust. When assigned a new leader to coach, I chose to spend much of my time on the floor with these leaders in order to understand their work conditions and the situations that they were in every day. My Sensei insisted on the Gemba (Japanese word meaning “where the work is done”) approach, and I came to understand why. The Gemba approach allowed me to gain true insight into their situations, where they struggled and where they excelled. They were proud to show me their production lines and introduce me to the people they worked for. Yes, I said the people they worked for; it was common for Toyota leaders to consider the people on the teams they managed to be people they worked for and not people who worked for them. This was a new mind-set for me but I came to see it as an essential element in establishing a TPS culture.

These Gemba sessions with the assigned leaders became something that looked forward to to every day. I hope I was able to add some value to those I was assigned to help, possibly through new insight and improved working relationships. But I am also sure that I learned much more from them than they learned from me. These Gemba sessions were the beginning of my journey to learn TPS from the people perspective as well as the technical manufacturing perspective. It was fascinating to see how TPS functioned. Not to be too dramatic, but it was like hearing a symphony with many components, parts, and people coming together at the right time to produce a quality product. When I work with clients today, I strive to help them develop this rhythm of work and unity of purpose.

I became more and more fascinated with TPS and had a strong desire to learn more about not just the production part of TPS, but how it evolved and how people functioned within the system. I shared this with my Sensei and she said, “Darril, you have the people part of the TPS equation. If you can combine that with the technical aspect, then you will have a powerful combination. Learn the principles behind the tools and how respect for people (customers, team members, society) drives the system.” And so that became my objective: to understand this connection between people and process, the elements that make TPS one of the most studied but least understood work systems.

THE TOYOTA WAY 2001

In 2001, Toyota developed the internal document called The Toyota Way 2001. Toyota had grown very quickly around the world and struggled to convey the essence of what makes the company great to its newer associates. When Toyota was a small company and centrally located in Japan, it was possible for senior leaders to teach team members in groups or one-on-one. The rapid growth made it impossible to disseminate the Toyota Way in the same fashion. Under the direction of then Toyota Motor Corporation President Fujio Cho, Toyota’s Global Human Resources Division researched and developed The Toyota Way 2001 as a way to communicate to global Toyota team members the “DNA” of Toyota. In the introduction, Mr. Cho states, “In this booklet we have identified and defined the company’s fundamental DNA, which summarizes the unique and outstanding elements of our company culture and success. These are the managerial values and business methods that are known collectively as The Toyota Way.”

In true Toyota form, the “Way” was condensed into a thirteen-page booklet. Someone once told me that they heard that the booklet took ten years to write. I told them I was not sure but it sounded right and added that it probably took one year to write one-thousand pages and nine years to condense it to thirteen pages!

Once published, Mr. Cho challenged each global region to disseminate the Toyota Way to the people at their locations. I was fortunate enough to have the responsibility to develop the program we would use in Kentucky to teach members of the management team. During the development process, I was able to meet and learn from the great leaders at Toyota Motor Manufacturing Kentucky.

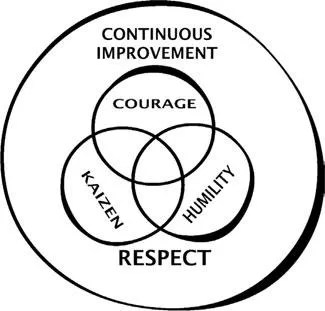

Here I share the Honsha version of The Toyota Way that is based on the foundational Lean principles of Continuous Improvement and Respect. Within these two principles lies the heart: Courage, Humility, and Kaizen. Toyota uses slightly different words; here I have attempted to take the original concepts and find the deeper root.

An example is Genchi Genbutsu. This is a key element of The Toyota Way and is often quickly translated into “Go and See.” As with many Japanese words, the quick translation fails to capture the essence of the word. At the Kentucky plant, many people used the phrase “Go and See” in place of Genchi Genbutsu but often the action was “Go and Watch” or “Go and Do,” neither of which captured the essence of Genchi Genbutsu. When I asked one senior executive, Hiro Yoshiki, what Genchi Genbutsu meant to him, he explained the purpose [my paraphrase] as follows: “The most important reason to ‘Go and See’ is to learn, learn deeply about the situation and what is needed from you. The second reason is to teach by asking the questions that lead team members to correct answers. The third reason is to be seen.” This third reason did not sound very humble to me but I came to realize the meaning. By being seen, you are able to convey to everyone that the situation is important to you and that the people working on the problem are important. You and others also build a mutual understanding of the situation and thus can arrive at solutions quickly. This was a key learning point for me. The fourth reason to go and see, said Hiro, is so you do not have to go and see anymore. This sounded very strange to me until he explained further. “We want to go and see but not the same problems again and again; we want to see new problems. Plus, if the time is taken to teach, then problems are avoided in the future because team members have a higher skill level.”

If we are to learn, teach, show respect, and develop others, we must go to the part of our business where value is created for the customer. In manufacturing, we call it the “Floor”; others call it the “front line.” Whether it is manufacturing or service or a nonprofit agency, the message is still the same: Show your learning spirit, your humility by practicing Genchi Genbutsu!

COURAGE, HUMILITY, KAIZEN AT THE HEART

When we develop Courage and Humility we will then be able to practice Kaizen. These three elements work together and allow us to show respect for people and to develop a culture of Continuous Improvement. It was during my study of TPS with OMDD that Courage, Humility, and Kaizen came to life.

OMDD uses emersion as the preferred way to teach TPS. My first lesson was early one Monday morning at a parts supplier’s plant location. With little more than an introduction, we started and I was taken to a work cell that made hinge parts for car seats. My Sensei told me, “Darril-san, this is your work area; please find 100 problems, I will return in 2 hours to see your list.” This was all very new to me. I had spent many hours observing the well-oiled, highly efficient production line at Toyota. But this was obviously not Toyota. The production area was a mess; there was no standard work and no hint or any kind of order. In this case, it seems that identifying waste would be even easier. But it was not. I do not know if it was a lack of experience or a lack of confidence but I found it difficult to see any problems, let alone a hundred problems in two hours. How would I do that? Just getting organized as to how I would observe was difficult so I observed the team members and the machines from outside the cell, pacing around it like a timid puppy for two solid hours, looking for the elusive problems. At the end of the two hours, my Sensei returned to find that I had exactly two problems on my list. I was ninety-eight problems short of the goal!

He looked at me and then wiped his hands over his head and down to his face. He must have been thinking, “Oh my, what kind of idiot do I have here?” After he composed himself, he said, “Tell me what you see.” So I described to him what the team members were doing but that I did not see any problems. I still struggled to identify the problems. My skill level was so low that one obvious item not on my list was a neatly hung mallet that was used to slam each part into one of the machines. This problem should have been obvious to anyone! At least they had it on a string so the team member did not have to reach very far for it; that should make it good, right? I was so naive.

At this point he was even more frustrated. “Darril-san, come with me,” he said. In a private meeting room with a flipchart, he started to explain to me how to observe in order to deeply understand the work. He explained that at first that it is not my job to correct the work but to understand it, then to make improvements. I had long been an admirer of Dr. Stephen Covey’s The Seven Habits of Highly Effective People and what he was explaining to me was Habit 5, “Seek First to Understand, Then to be Understood.” From this perspective it really made sense to me. This was also a fundamental lesson in The Toyota Way element of Humility. Humility insists that we understand so that we may develop better solutions. Taiichi Ohno said, “Observe the production floor without preconceptions and with a blank mind.” This is what my Sensei was trying to teach me with actions, not just words.

He continued to teach me his approach, and he wrote the word “Muri” on the flipchart. He explained that Muri is part of the three Ms of waste: Muri, which translates as overburden; Mura, which translates as unevenness; and Muda, the most famous element, which translates as waste and has seven components. He explained that we must approach our deep understanding of the process first from the perspective of the people doing the work. We must look for Muri and eliminate it from the process. We must also send the correct message that our purpose is first to improve the work for the people doing the work. This will help us gain buy-in with the team when we go deeper into the improvement process. At this point we only looked at Muri. He asked me to list what I observed in the process that could be considered Muri. I recognized that using the mallet to hit each part, several hundred times per day, would be considered overburden, so that finally made it to my list. I could see walking inside the cell as overburden. My list had grown somewhat, but from my Sensei’s perspective it was still incomplete. “Darril-san,” he asked, “what is the best way to increase your understanding of the process and your ability to see the Muri?”

“I will observe more closely and with an eye for Muri,” I replied.

“This would of course be helpful, but what can you do that would deepen your understanding more quickly?”

“Are you saying I should actually learn the job?”

“I am not saying, I am asking.”

“Then I will need to learn the job in order to more deeply understand the process and to see the Muri more closely.”

Now the lesson of Humility was even more profound. Not only was I learning new skills from a Lean/TPS perspective, but I also needed to learn how to do the manufacturing job I was observing. I was not only a student of the Sensei, but now also a student of the team members I had been observing. I approached the team and asked if they would teach me their work process. They all smiled as if to say, this is going to be fun! “Of course,” they said.

After donning the appropriate personal protective equipment, I started on the first machine in the process that connected the first two flat steel plates and began to turn them into seat hinges. This had looked so easy from the outside looking in. The team member teaching me the job had several laughs as I fumbled to keep up with the speed of the process. I would turn the raw material the wrong way, drop the parts, and was very slow and awkward. After a day on the job, I was able to pick up the process and do it with help from the team member assigned to me. I was not able to do it as quickly or with the quality of the team member, but with her help I understood the process much more deeply. Looking through the lens of Muri, I was able to add many problems to my list.

The next machine was the infamous “mallet hanging from a string machine” that I mentioned previously (Figure 1.4). The first action was to pick up a flat steel part, apply gooey lubricant with a brush to the section that would be moving against the previous piece; then put this into the machine by placing a hole in the part onto a small peg in the machine, and then smack the part with the mallet so it fit tightly even if it was already tight. Well at least it was standardized. This seemed very wrong but I wanted to learn from the worker perspective so I did as instructed. As I did this process, I realized that smacking the part with the mallet was indeed overburden and caused a bit of pain at the end of the rotation—not to mention the possible damage to the part itself. I also realized that the reason the parts did not always fit snuggly on the small peg was that the peg had become worn over time and when the part was even slightly off center, the peg might not allow the part to fit correctly. The mallet was obviously a countermeasure to this problem but it was not the result of deep, 5-Why problem solving. In this case, as in many others, the result of shallow problem solving is more burden on the worker. This was powerful learning for me.

One process called for the worker to add pins and grommets to a machine for processing. The hand motions used required reaching, handing off the parts from one hand to the other, and crossing arms to place the parts in the machine. This is also a burden on the worker…my list was growing.

Over the next couple of days I learned each process in this same way. When my Sensei came back and asked me what problems I had on my list, I showed him that the list had grown, and he seemed a bit more pleased. He asked me if I had not seen these same things before. Of course, I had seen the steps in the operation while I observed the process, but not through the eyes of Muri. I also discovered that I was hesitant to judge the steps in the process. When I observed the process and saw something questionable, like the mallet, I told myself, “There must be a perfectly good reason for doing that.” When I told my Sensei about this rationalization of what I was seeing, he said, “When you observ...

Table of contents

- Cover

- Title Page

- Copyright Page

- Table of Contents

- Foreword

- Introduction

- About the Authors

- Chapter 1 Courage, Humility, Kaizen

- Chapter 2 Stability and Standardized Work

- Chapter 3 Jidoka

- Chapter 4 Just-In-Time and Kanban

- Chapter 5 Problem-Solving PDCA

- Chapter 6 Toyota Kaizen Methods

- Chapter 7 Kaizen Culture: The Continuous Improvement Engine

- Chapter 8 Elimination of Waste in Product Design

- Chapter 9 Adapting Lean for Made-to-Order/High-Mix, Low-Volume Organizations

- Chapter 10 Lean Logistics

- Chapter 11 Leading a Kaizen Culture

- Chapter 12 Hoshin Kanri

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Toyota by Toyota by Samuel Obara,Darril Wilburn in PDF and/or ePUB format, as well as other popular books in Business & Operations. We have over one million books available in our catalogue for you to explore.