eBook - ePub

Constitutive Models for Rubber VI

- 534 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Constitutive Models for Rubber VI

About this book

Recent developments in order to represent the material behaviour of filler-reinforced elastomers under realistic operating conditions are collected in this volume. Special topics are finite element simulations and methods, dynamic material properties, experimental characterization, lifetime prediction, friction, multiphysics and biomechanics, reinf

Trusted by 375,005 students

Access to over 1 million titles for a fair monthly price.

Study more efficiently using our study tools.

Information

Foreword (Volume 1)

The extraordinary stress-strain behavior of rubber has presented an opportunity for inventive engineers and a challenge for scientists since the mid-nineteenth century, and continues to do so today. Major branches of theory, such as the statistical theory of rubber elasticity and finite strain elasticity theory, have been spawned by the properties of rubber. Until recently, however, the theoretical framework for large deformations found little application among rubber engineers because the mathematics rapidly becomes intractable for all but the simplest components. The advent of affordable and powerful computers has changed all this, and brought the challenge of rubber to new sets of people—software engineers and desk-top, as opposed to empirical, designers.

The development of the statistical theory of rubber elasticity in the 1940s, of finite strain elasticity theory in the 1950s, and of convenient forms for the strain energy function in the 1970s, all focused on modelling the elastic characteristics of rubber. Although much literature has appeared in recent years following this theme, the Physics of Rubber Elasticity by L.R.G. Treloar (3rd Edition, Clarendon Press, Oxford, 1975) and the proceedings of a Discussion on Rubber Elasticity (Proc.Roy.Soc.London, 1976, A351, No. 1666, 295-406) remain very valuable reviews.

The treatment of rubber as a ‘hyperelastic’ material—that is, a material modelled by a strain-energy function for finite strain—was implemented into finite strain element analysis in the 1980s and is now widely available in commercial software packages.

However, only a few engineering elastomers—such as unfilled natural rubber and some grades of polyurethane—really conform to the “hyperelastic” ideal. Most other engineering elastomers incorporate “reinforcing” fillers, needed to confer adequate strength properties and also to improve processing characteristics and to enable adjustment of hardness over a wide range. The stress-strain characteristics of such filled elastomers depart significantly from elasticity. Whileways of thinking about these departures—such as “dynamicto-static ratio” of rubber springs—may have satisfied a previous generation of design engineers, there is now an opportunity to apply more sophisticated models.

One major current challenge is thus to model those aspects of the inelastic behaviour that are relevant to engineers, and to do this in such a way that the models are implementable in finite element analysis.

Although potentially the involvement of representatives of several disciplines should facilitate progress, this is only the case if they talk to each other. In practice, software engineers might rely on the literature and on desktop designers as sources of information about rubber, and fail to achieve as good a balance of understanding as they could if they listened also to experimental rubber scientists and empirical designers. Applied mathematicians might develop phenomenological models which address issues of secondary interest to designers, or which misrepresent important aspects of the experimentally observed behaviour. Experimentalists might develop models without reference to the existing framework of continuum mechanics, resulting in internal inconsistencies and difficulty in implementation in software packages. The First European Conference on Constitutive Models for Rubber sprang from the idea of providing a forum for multi-disciplinary discussion, seeking to bring the fragmented strands of recent research together.

Within the UK a start has been made in this direction—through a workshop on Deformation Modelling for Solid Polymers (Oxford University, 1997) and a seminar on Finite Element Analysis of Elastomers (Institution of Mechanical Engineers, London, 1997). The proceedings of the latter are available as a publication of the same name (Professional Engineering Publications, London, 1999). Similarly, in Germany a workshop of Finite Element Analysis—Basics and FutureTrends was organised by the Deutsche Institute für KautschukTechnology (Hannover, 1998). The interest in these essentially national meetings suggested that further cross-fertilisation should be stimulated by providing a European forum for discussion.

The contributions to this Proceedings cover a wide range of subjects. Consistent with the analysis given above, relatively few authors chose to present hyperelastic models for rubber; however, readers interested in this topic will find ample references to earlier work. Several contributions address inelastic effects associated with filled elastomers—such as Mullins’ effect and quasi-static hysteresis. For others—most obviously in processing uncured rubber—the interest is in modelling viscoelasticity. In addition to stressstrain behaviour, work is presented on frictional contact and on mechanical failure. Looking at the applications side, computational techniques are addressed and applied to a diverse range of components, including tyres, earthquake isolation bearings and intervertebral discs. Overall, the authors have achieved progress in a wide range of areas—including experimental results, theory and practical utility. They raise many questions as well, as one might expect from the first forum of this kind.

We would like to thank our colleagues on the Scientific Committee (R.W Ogden, Chairman; D. Besdo, R.de Borst, K.N.G. Futler, H.A. Mang, H. Menderez, G. Meschke and H. Rothert) and all the authors who have worked with us to produce this book.

A. Dorfmann

A.H. Muhr

Vienna/Hertford, June 1999

A.H. Muhr

Vienna/Hertford, June 1999

Sponsors

The organizing committee gratefully acknowledge the support received from the following sponsors.

Accelerated ageing of polychloroprene for marine applications

V. Le Saux, Y. Marco & S. Calloch

Laboratoire Brestois de Mécanique et des Systèmes (EA4325), Brest, France

P.Y. Le Gac

Ifremer—Service Matériaux et Structures, Plouzané, France

N. Ait Hocine

Laboratoire d’Ingénierie des MATériaux de Bretagne (EA4250), Brest, France

ABSTRACT: The accurate evaluation of the lifetime and mechanical properties of rubber-like materials is of particular interest for designers in order to ensure the reliability of such materials and the safety of structures. This is especially true for sensible applications, like offshore pipelines or dry dock seals, needing frequent maintenance operations. The frequency of these operations, and thus their cost, could be reduced by a better understanding of rubber-like materials ageing. To reduce the time cost of this evaluation, accelerated ageing tests using temperature, acid or humid environments as acceleration factors are usually carried out. However, these tests convey unavoidably some artificial phenomena like diffusion limited oxygen, which makes difficult the use of the results. In this study, we focused on a polychloroprene rubber, aged under several accelerated conditions (renewed natural seawater and air ageing both for temperature ranging from 20°C to 80°C). Physical measurements (IR and Raman analysis) are carried out to understand the mechanisms involved in the material degradation. Several mechanical tests are also achieved (uniaxial tension and instrumented micro-hardness tests) in order to observe the consequences of the degradation of the material on its mechanical behaviour.

1 INTRODUCTION

Polychloroprene rubbers are used in various fields thanks to their good constitutive mechanical behaviour, their ability to be effective towards ageing effects and their good resistance to hydrocarbons or aggressive environments such as seawater. For example, they can be found in dry dock seals and offshore applications (pipelines). These structures can spend several years underwater, either continuously or intermittently, and the material selected must be shown to retain its mechanical properties.

Ageing is a complex phenomenon that covers a broad spectrum of multidisciplinary domains from the description of physico-chemistry to the structural analysis with properties gradients (Ofta 2003). To evaluate the durability of a structure, three main requirements are needed:

- the development of experimental techniques that allow the identification of the ageing mechanisms and the main factors controling their kinetics;

- the reduction of studies duration using accelerated ageing experiments whose reliability must be controlled;

- the identification of models for the indicator evolutions identified on samples aged in real or accelerated conditions.

Ageing was for a long time, and still remains nowadays, chemist business. However, lifespan prediction models and relevant end-of-life criteria are based on mechanical concepts. Any ageing study would thus have to contain two aspects. The first one is dedicated to the description of the material microstructure modifications related to the degradation mechanisms occurring at a microscopic scale and to the development of kinetic models in order to predict the microstructure evolution (Gillen et al. 1995) or (Colin et al. 2004). The other one relied on the consequences of these microstructure changes on the macroscopic mechanical properties (Woo and Kim 2006). For both aspects, accelerated ageing experiments to reduce the time characterization are required. An extrapolation to service condition can be realized under certain conditions using for example Arrhenius approach (or any method based on time-temperature superposition principle). The literature shows that most of the studies focus on only one aspect, few studies tried to link these aspects (Celina et al. 2000). This observation can be explained by the gap between the chemical and mechanical scales.

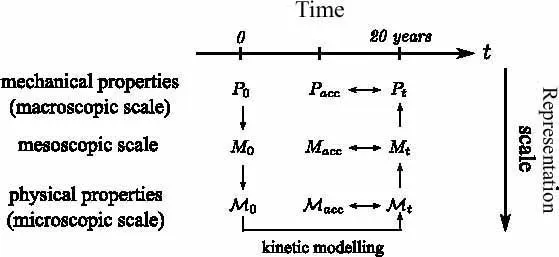

Figure 1. Ideal method for the study of a material ageing.

The aim of this study is to reduce the gap between these aspects in order to be more confident in ageing prediction. To reach this goal, the first requierement is to use relevant accelerated ageing conditions. Mechanical and physical experiments are then performed on aged samples. The aim of the first ones is to observe the influence of ageing on classical mechanical macroscopic properties, whereas the aim of the second ones is to identify the ageing mechanisms as a step towards a kinetic model. To make the link between macroscopic and microscopic scales easier, an intermediate scale is added, representative of both approaches. Figure 1 summarizes the method we would like to set-up to predict the evolution of the mechanical behaviour.

2 ACCELERATED AGEING PROTOCOLS

2.1 Materials

The samples studied are polychloroprene rubbers afforded by Trelleborg Offshore. For each ageing conditions, a batch of samples is taken from the vessels for several durations. Each batch is composed of one 2 mm-thickness sheet of dimensions 150 × 150 mm2, one 8 mm-thickness sheet of dimensions 100 × 150 mm2, one compression plot, four AE2 samples and two pure shear specimens.

2.2 Accelerated ageing conditions

One key aspect of any ageing studies is the development of relevant accelerated ageing protocols. The aim of these tests is to reduce the characterization time. This is achieved using acceleration factors such as temperature, acid or humid environments. The fundamental aspect of these tests is that they must be representative of natural ageing, i.e. only the kinetics of the ageing mechanisms are modified, not the mechanisms themselves. Therefore, the environment in which ageing is realized have to be the same than the natural ageing one. Laboratory ageing was performed in sealed vessels containing renewed natural seawater maintained at different temperatures (20°C, 40°C, 60°C and 80°C) and realized at the Ifremer (center of Brest). A thermo-oxydative ageing in air-circulating oven at 40°C, 60°C, 80°C is also realized in order to compare the effect of the ageing mechanisms on the constitutive mechanical behaviour (these results will not be discussed in this paper).

2.3 Reference state

During the ageing, seawater is absorbed into the polymer by a diffusion mechanism. As water is acting as a plasticizer, the mechanical behaviour depends on the ageing degree but also on the amount of absorbed water. In order to be able to compare results and to analyse only the consequence of ageing effects (and not the effect of water), all the experiments were carried out after water loss, i.e. after mass stabilization, reached at room temperature.

3 MECHANICAL OBSERVATIONS

3.1 Uniaxial tension results

Normalized t...

Table of contents

- Cover

- Title Page

- Copyright

- Table of Contents

- Foreword

- Foreword (Volume 1)

- Sponsors

- Ageing

- Computational Methods FEM Implementation

- Continuum Mechanical Models

- Dynamic Properties and Vibration

- Experiments and Characterisation

- Fatigue and Lifetime

- Friction

- Fracture and Crack Propagation

- Industrial Applications

- Micro- and Macromechanical Approaches

- Multiphics and Biomechanics

- Reinforcement

- Stress Softening

- Author index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Constitutive Models for Rubber VI by Gert Heinrich,Michael Kaliske,Alexander Lion,Stefanie Reese in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Civil Engineering. We have over one million books available in our catalogue for you to explore.