- 124 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Design and Use of Pressure Sewer Systems

About this book

This valuable text gives previously unreported experience in the design, operation and maintenance of pressure sewers. Economic advantages of the pressure sewer system allow development of previously undeveloped areas-making central sewer extension more affordable for both municipalities and developers. Pressure systems make central sewers available where on-site disposal may prove undesirable. Of interest to a broad spectrum of professionals, this new book will prove valuable to consulting engineers, municipalities, sewer districts, sanitary engineers, pump and equipment manufacturers, and developers.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Design and Use of Pressure Sewer Systems by David Thrasher in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Environmental Management. We have over one million books available in our catalogue for you to explore.

Information

1

Introduction

Currently, the field of wastewater engineering is in an extremely dynamic period of development. Due to the high cost of wastewater collection systems, engineers are reevaluating old ideas concerning wastewater collection and new concepts are being formulated.

The traditional mode of collection for wastewater has been gravity sewers. One problem with this traditional solution has been the obvious fact that gravity sewers must slope downhill. This creates a situation where deep cuts are often required and large, expensive pump stations are often necessary. In addition, the design engineer is faced with a situation where the location of any new collection main is very limited. Many times, these disadvantages will mean that areas with extreme variations in terrain or with other limitations will remain unsewered, sometimes to the detriment of public health. All of these disadvantages serve to increase the overall cost of any wastewater collection system.

Table 1-1 provides the reader with a general list of disadvantages of conventional gravity wastewater collection systems.

For most wastewater disposal projects, the collection system is usually by far the most expensive portion of the project, while the treatment plant is usually a comparatively small expense. In many rural systems, it is common for 80 percent or more of the total cost of a sewer system to lie in the collection system which means that less than 20 percent of the cost would be in the treatment facilities.4,10 Areas which are more urban in nature, where homes are very close together and where topographic obstacles are not severe, are usually amenable to conventional sewerage systems. However, in sparsely settled communities, in hilly terrain, or in areas where rock excavation or groundwater present problems, costs represented by the collection system can become too great to bear.

|

1) Infiltration and inflow are commonly encountered.

2) Downhill slope must be maintained at all times.

3) Large, expensive pump stations are required in those instances where downhill slopes cannot be maintained.

4) Large diameter (8” or larger) pipe is required to transport the solids commonly found in wastewater.

5) There is very little flexibility in the location of gravity sewer collection mains.

6) Deep utility trenches are often required which leads to such expensive construction techniques as trench shoring and dewatering. |

Since most on-site wastewater disposal systems cost significantly less than centralized sewer, the on-site approach has been generally employed in areas where on-site disposal is applicable. Difficulties have arisen in areas where conventional on-site systems have failed due to unfavorable soil conditions. The typical result from this condition has almost invariably been a recommendation to provide central sewer for the community. Implementation of this recommendation has been dependent on the financial status of the community, availability of federal grants, and public attitude. Experience has shown that the cost of conventional sewers is extremely high for most small communities. In fact, it is not uncommon to see construction cost estimates in excess of $10,000 per home.4

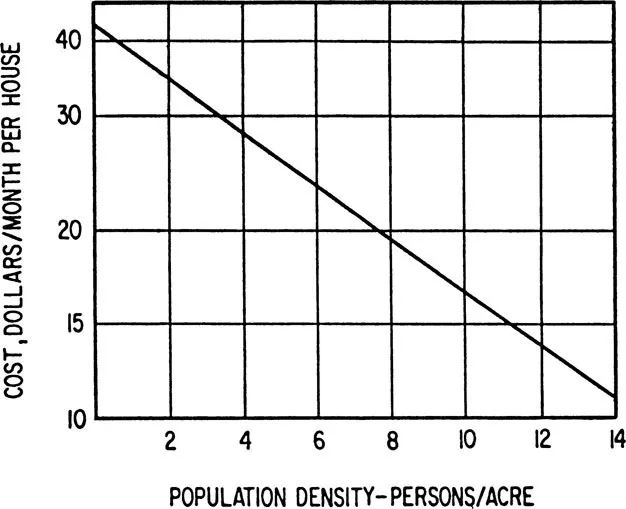

The overall cost of any wastewater collection system project is important; however, the cost per user is even more important. Without addressing existing discussions on the merits and demerits of federal grant programs and centralized collection and treatment systems, it is sufficient to note that the cost of conventional sewers is extremely high for most small communities. Also, since the cost of the conventional collection system generally represents a majority of the total system capital cost in rural areas, cost reductions in the collection system can have a significant impact on the overall cost of a sewage system. Figure 1-1 illustrates the inverse relationship between cost and population density, which is primarily explained by the greater length of sewer main per contributor. Other explanations for the high capital cost of conventional wastewater collection systems are regulations which limit the smallest sewer pipe diameter and grade and alignment requirements which often result in deep cuts and expensive lift stations.

Due to the high cost of conventional gravity sewers, many areas remain unsewered today, and these areas have generally retained septic tank-soil absorption systems as the means of wastewater disposal. Even though septic tank-soil absorption systems have an enviable record of performance, many limitations exist. Soil type and depth must be adequate, and population density should remain low. It has been estimated that as much as 65% of the United States contains sufficient limitations on the use of septic tank-soil absorption systems that could severely limit their effectiveness.9

For an area that is not conducive to the on-site disposal of human waste and cannot afford the high cost of conventional wastewater collection systems, innovative collection alternatives should be considered. One such alternative to consider should be a pressurized sewer system.

2

History of Pressure Sewers

The concept of grinder pressure sewers was first proposed by Dr. Gordon M. Fair, Professor of Sanitary Engineering at Harvard University, in 1954. His idea of pressure sewers was part of a combined sewer system that would entail hanging a pressurized sewer pipe within a gravity storm sewer pipe. The object was to pump the domestic sewage through the pressure pipe and convey storm water by gravity, thus eliminating the need to build a separate sanitary sewer system in some highly populated areas.

The first published experience in the design and installation of pressure sewers came from an engineer in Kentucky who designed a pressure sewer system for installation in a section of Radcliffe, Kentucky. This small demonstration project, installed in 1964, served 48 homes.3 This system was later dismantled and replaced by a gravity sewer system.2

In 1966, the American Society of Civil Engineers (ASCE) initiated a study under a federal grant in an attempt to prove Dr. Fair’s theory concerning pressure sewers. Three years later, ASCE published a final report which concluded that Dr. Fair’s concept of combined sewers was not economical. However, the report did state that small-diameter, low-pressure sewer systems offered a potential cost-effective alternative to conventional gravity sewers, especially where installation of gravity sewers was considered uneconomical or infeasible.43

The oldest known pressure sewer system in existence today was installed in 1968 and serves a permanent houseboat community located on the Columbia River near Portland, Oregon. In this system, each houseboat has a 1/2-horsepower sewage ejector (solids handling) pump located in a basin attached to the side of the houseboat. There are about 700 pumps in operation, with 150 pumps operating in parallel within one section of the system. This system has operated successfully for over 16 years, and it is one example of the performance of a pressure sewer system utilizing centrifugal pumps in parallel operation.

The subsequent development of pressure sewer systems has fallen into two categories; first, grinder pump pressure sewer systems, and second, pumped effluent or Septic Tank Effluent Pumping (STEP) pressure sewer systems.

2.1 GRINDER PUMP PRESSURE SEWER SYSTEMS

As part of the ASCE study, General Electric Company developed a grinder pump in 1967–68 that was to be used as part of the field demonstration. Due to budget considerations, this particular field demonstration was never accomplished. However, the New York Department of Environmental Conservation’s Research & Development Unit decided to sponsor a demonstration with United States Environmental Protection Agency (USEPA) grant funding to determine the feasibility of a grinder pressure sewer system at Albany, New York.5

In addition to Albany, New York, the USEPA also funded full scale evaluations of grinder pump pressure sewer systems at Phoenixville, Pennsylvania,6 Grandview Lake, Indiana,7 and Bend, Oregon.67

The Albany, New York Pressure Sewer System consisted of 12 grinder pumps. The pressure main for that system was oversized to allow for all units to operate simultaneously. It was reported that subsequent accumulations of grease and fibrous materials within the pipes reduced some pipe cross-sectional areas by as much as 40%. In addition, the wastewater was found to be more concentrated than normal, apparently due to lack of infiltration in the pressure sewer system.5 Indirect evidence of reduction of the pipe cross-sectional area by grease was also found at Phoenixville.6 Grandview Lake also reported grease problems, faulty operation of automatic air release valves, and grease buildup on flow measuring devices at the wastewater treatment plant.4

The Grandview Lake Project was installed near Columbus, Indiana in late 1971. The system was a combination grinder and effluent pressure sewer demonstration project, and it consisted of 58 house connections in the first phase. The majority of the pumps were grinders along with a few STEP pumps.7

A more recent example of grinder pump system installation is within the Pennsylvania Pocono Mountains. Here there are numerous private land developments which consist primarily of seasonal occupancy dwellings. As of 1982, over 750 units had been installed and numerous future units were being planned. Pressure sewer was chosen for this locale because it provided advantages in land planning and because of economic advantages which included lower initial capital cost. Pressure sewers were well suited to the rocky and hilly terrain and to the layout of houses in interspersed clusters at different locations within the mountains. Early development in this area was served by gravity sewers, but after examination of the advantages of pressure sewers, most development since 1974 has been grinder or effluent pressure sewer.2

2.2 STEP PRESSURE SEWER SYSTEMS

Pumps to convey septic tank effluent have been in use for many years in individual home applications. In these situations, the unit would normally pump the effluent from a septic tank to a soil absorption field some distance from the home and normally at a higher elevation. Cooper Communities, Inc., a large community developer in Arkansas, reports that they have been installing systems such as this within their developments since 1958.66

Rose8 is generally credited as one of the first proponents of STEP systems. He proposed this concept to the Farmers Home Administration as a solution to sewage problems in rural communities as early as 1967.

At about the same time, Harold Schmidt, of the General Development Corporation Utility Company, Miami, Florida, initiated a feasibility study of pumping septic tank effluent as a basic premise for a pressure sewer system. Based on this investigation, a small pressure system was installed at the Port Charlotte, Florida development in 1970. Forty homes were connected to the system and the pressure sewer from these homes discharged directly into an extended aeration treatment plant. This was the first treatment plant to be designed specifically for treating septic tank effluent. A year later, General Deve...

Table of contents

- Cover

- Title Page

- Copyright Page

- Preface

- Acknowledgments

- Table of Contents

- 1. Introduction

- 2. History of Pressure Sewers

- 3. General Information Concerning Pressure Sewer Systems

- 4. Preliminary Design Concepts and Considerations

- 5. Final Design Considerations

- 6. Design Methodology

- 7. Equipment and Material Considerations

- 8. Characteristics of Pressure Sewage

- 9. Operation and Maintenance

- 10. Existing Design Manuals and Publications

- Bibliography

- Glossary

- Index