Semiconductor Packaging

Materials Interaction and Reliability

- 216 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

About this book

In semiconductor manufacturing, understanding how various materials behave and interact is critical to making a reliable and robust semiconductor package. Semiconductor Packaging: Materials Interaction and Reliability provides a fundamental understanding of the underlying physical properties of the materials used in a semiconductor package. By tying together the disparate elements essential to a semiconductor package, the authors show how all the parts fit and work together to provide durable protection for the integrated circuit chip within as well as a means for the chip to communicate with the outside world. The text also covers packaging materials for MEMS, solar technology, and LEDs and explores future trends in semiconductor packages.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

section three

Materials used in semiconductor packaging

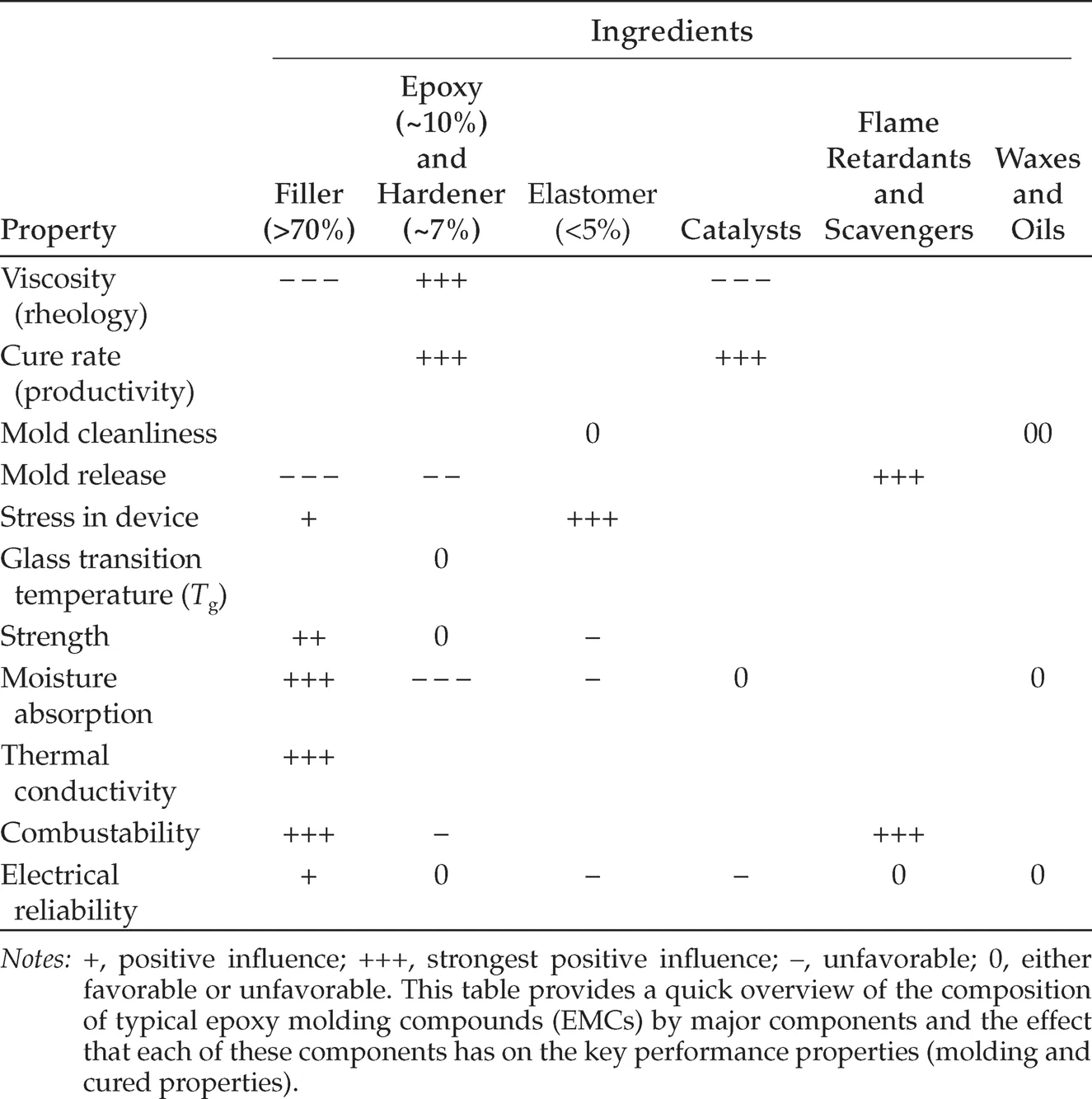

6.1 Molding compounds

6.1.1 Objectives

6.1.2 Introduction

6.1.3 Background

6.1.4 Newer formulations

6.1.4.1 Biphenyl

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Table of Contents

- Preface

- Authors

- Partial list of abbreviations, acronyms, and symbols

- Section I: Semiconductor packages

- Section II: Package reliability

- Section III: Materials used in semiconductor packaging

- Section IV:—The future

- Glossary

- Appendix A: Analytical tools

- Appendix B: Destructive tools and tests

- Index

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app