eBook - ePub

Chemical Admixtures for Concrete

- 456 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Chemical Admixtures for Concrete

About this book

Chemical admixtures are used in concrete mixtures to produce particular engineering properties such as rapid hardening, water-proofing or resistance to cold. Chemical Admixtures for Concrete surveys recent developments in admixture technology, explaining the mechanisms by which admixtures produce their effects, the various types of admixtures avail

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Chemical Admixtures for Concrete by Noel P. Mailvaganam,M.R. Rixom,Daniel P. Manson,Carol Gonzales in PDF and/or ePUB format, as well as other popular books in Architecture & Architecture Methods & Materials. We have over one million books available in our catalogue for you to explore.

Information

Chapter 1

Water-reducing agents

1.1 Background and definitions

The water-reducing admixtures are the group of products which possess as their primary function the ability to produce concrete of a given workability, as measured by slump or compacting factor, at a lower water-cement ratio than that of a control concrete containing no admixture.

The earliest known published reference to the use of small amounts of organic materials to increase the fluidity of cement containing compositions, was made in 1932 [1] where polymerized naphthalene formaldehyde sulfonate salts were claimed as useful in this role. This was followed during the mid 1930s to early 1940s by numerous disclosures regarding the use of lignosulfonates and improved compositions [2–9].

The lignosulfonates formed the basis of almost all the available water-reducing admixtures until the 1950s when the hydroxycarboxylic acid salts were developed which have grown to occupy a significant but, nevertheless, still a minority position in this product group. Materials such as glucose and hydroxylated polymers obtained by the partial hydrolysis of polysaccharides have been widely used in North America. The polymers usually have a low molecular weight and contain glycoside units ranging from 3–25. In addition, other chemical and admixture types have been included into the water-reducing admixtures formulations to produce five types within this category.

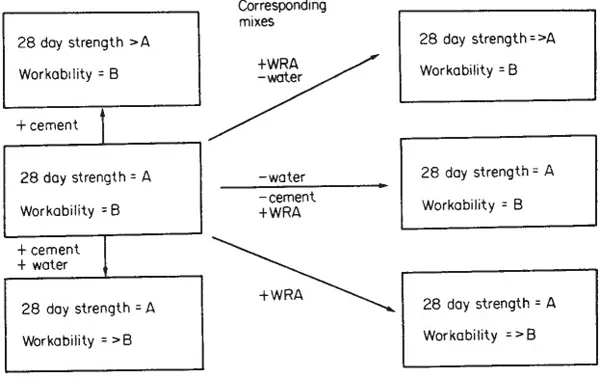

The normal water-reducing admixtures allow a reduction in the water-cement ratio at a given workability without significantly affecting the setting characteristics of the concrete. In practice, this effect can be utilized in three ways:

- By the addition of the admixture with a reduction in the water-cement ratio, a concrete having the same workability as the control concrete can be obtained, with unconfined compressive strengths at all ages which exceed those of the control.

- If the admixture is added directly to a concrete as part of the gauging water with no other changes to the mix proportions, a concrete possessing similar strength development characteristics is obtained, yet having a greater workability than the control concrete.

- A concrete with similar workability and strength development characteristics can be obtained at lower cement contents than a control concrete without adversely affecting the durability or engineering properties of the concrete.

In all three ways of use, this type of admixture can be regarded as a cement saver, as illustrated in Fig. 1.1.

Corresponding mixes are, therefore, concrete mixes having the same workability and 28-day strength characteristics, but the mix containing the water-reducing admixture will have a lower cement content than the other mix. In practice, of course, the parameters of workability and strength are dictated by the requirements of the particular situation; in areas of high steel content, a high workability will be required, whilst in the production of extruded prestressed lintels, a very low workability is needed. In both cases the strength requirements will be dictated by the load-bearing characteristics of the application. Thus in comparing any properties of admixture-containing concrete, the results of corresponding mixes should be studied, whether the investigation be related to strength, durability factors or statistical considerations, such as standard deviation.

Although the pictorial comparison shown in Fig. 1.1 and discussed above is true at low and average cement contents up to about 350 kg m-3 it is more difficult to obtain higher strengths and workability by further increasing the cement content. It is in this area that the hydroxycarboxylic acid water reducing admixtures are particularly beneficial, enabling considerable increases in strength to be obtained without the expense and undesirable side effects of large cement increments.

Fig. 1.1 The concept of corresponding mixes.

The other members of the water-reducing admixture group possess some other function which could not be obtained by mix design considerations.

The accelerating water-reducing admixtures, whilst possessing the water-reducing capability of the ‘normal’ category, give higher strengths during the earlier hydration period and faster setting times which allow finishing operations to be carried out in a timely manner, particularly at lower temperatures.

A special type of the accelerating water-reducing admixture is finding increased application and is known in North America as a ‘mid-range water-reducing admixture’. This product type is formulated using water-reducing ingredients which have minimal set-retarding effects (such as low-sugar processed lignosulfonates, or blends of lignosulfonates with superplasticizers), high proportions of accelerators (chloride or non-chloride), and often a nonionic surfactant. The mid-range water-reducing agent can be used at higher dosages and hence give greater workability or water reduction without extending set times to unacceptable levels.

The retarding water-reducing admixtures again behave in a similar manner to the ‘normal’ materials and are often of similar chemical composition used at a higher dosage level, but extend the period of time when the concrete is in the plastic state. This means that the time available for transport, handling, placing and finishing is lengthened. In fact, although a few materials are available which exert only a retarding influence on concrete and have little or no water-reducing capacity, the v ast majority (about 95%) of materials called ‘retarders’ are actually retarding water-reducing admixtures and are considered as such in this book.

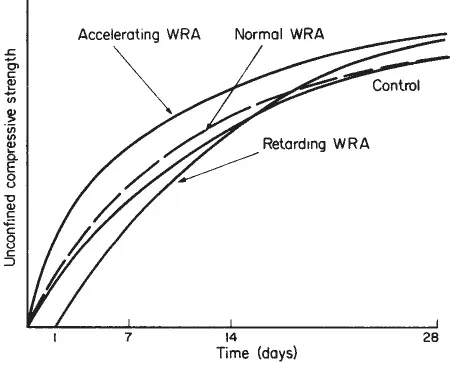

The way in which the four types of water-reducing admixtures discussed so far affect the strength gain characteristics of concrete containing them is shown in Fig. 1.2. The four concrete mixes have been designed to have approximately the same 28-day compressive strength, i.e. the admixture-containing mixes would contain approximately 10% less cement than the control mixes.

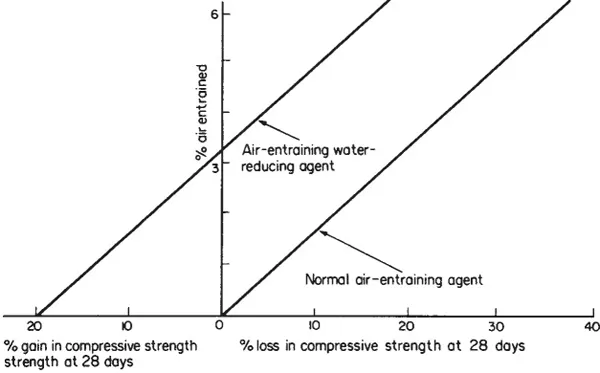

The air-entraining water-reducing agents possess the ability to entrain microscopic air bubbles into the cement paste whilst allowing a reduction in the water-cement ratio greater than that which would be obtained by the air entrainment itself. They are available in the normal and retarding form and also fall into two types depending on the level of air entrainment; the first type entrains only about 1–2% additional air and is normally used to increase the internal surface of the concrete to redress any deficiencies in fine aggregate gradings. The second type results in concrete containing 3–6% air and is used to enhance the durability of the concrete to freeze-thaw conditions.

Fig. 1.2 Compressive strength development of concrete containing various types of water-reducing admixture.

The advantages of using this type of material rather than a straight air-entraining agent are based mainly on minimizing the deleterious effect that air entrainment has on compressive strength, as shown in Fig. 1.3. Thus in a typical concrete mix, up to 3% air can be entrained without any alteration to the mix design or reduction in compressive strength when an air-entraining water-reducing admixture is used.

Fig. 1.3 The effect of air entrainment on compressive strength of concrete containing a water-reducing air-entraining agent and a normal air-entraining agent.

1.2 The chemistry of the water-reducing admixtures

Although the variety of admixtures that are commercially available are marketed under a multitude of benefit-orientated classifications, namely waterproofers, densifiers, workability aids, etc., it is possible to categorize the basic chemicals used as shown in Table 1.1.

It can be seen, therefore, that only three chemical materials form the basis of all the water-reducing admixtures, i.e. lignosulfonate, hydroxycarboxylic acid, and hydroxylated polymers.

1.2.1 Lignosulfonates

Lignin is a complex material which makes up approximately 20% of the composition of wood. During the process for the production of paper-making pulp from wood, a waste liquor is formed as a by-product containing a complex mixture of su...

Table of contents

- Cover Page

- Title Page

- Copyright Page

- Disclaimer

- Foreword to the third edition

- Acknowledgements

- Chapter 1: Water-reducing agents

- Chapter 2: Superplasticizers

- Chapter 3: Air-entraining agents

- Chapter 4: Concrete dampproofers

- Chapter 5: Accelerators

- Chapter 6: Special purpose admixtures

- Chapter 7: Application of admixtures