Pharmaceutical Quality by Design

Principles and Applications

- 448 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

About this book

Pharmaceutical Quality by Design: Principles and Applications discusses the Quality by Design (QbD) concept implemented by regulatory agencies to ensure the development of a consistent and high-quality pharmaceutical product that safely provides the maximum therapeutic benefit to patients. The book walks readers through the QbD framework by covering the fundamental principles of QbD, the current regulatory requirements, and the applications of QbD at various stages of pharmaceutical product development, including drug substance and excipient development, analytical development, formulation development, dissolution testing, manufacturing, stability studies, bioequivalence testing, risk and assessment, and clinical trials.Contributions from global leaders in QbD provide specific insight in its application in a diversity of pharmaceutical products, including nanopharmaceuticals, biopharmaceuticals, and vaccines. The inclusion of illustrations, practical examples, and case studies makes this book a useful reference guide to pharmaceutical scientists and researchers who are engaged in the formulation of various delivery systems and the analysis of pharmaceutical product development and drug manufacturing process.- Discusses vital QbD precepts and fundamental aspects of QbD implementation in the pharma, biopharma and biotechnology industries- Provides helpful illustrations, practical examples and research case studies to explain QbD concepts to readers- Includes contributions from global leaders and experts from academia, industry and regulatory agencies

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Introduction to Quality by Design (QbD): Fundamentals, Principles, and Applications

† Department of Pharmacy, Shri Venkateshwara University, Gajraula, India

‡ Department of Pharmaceutical Sciences, Shalom Institute of Health and Allied Sciences, Sam Higginbottom University of Agriculture, Technology & Sciences (SHUATS), Allahabad, India

§ Southern Institute of Medical Sciences, College of Pharmacy, Department of Pharmaceutics, SIMS Group of Institutions, Guntur, India

Abstract

Keywords

1 Introduction

2 Evolution of QbD concept

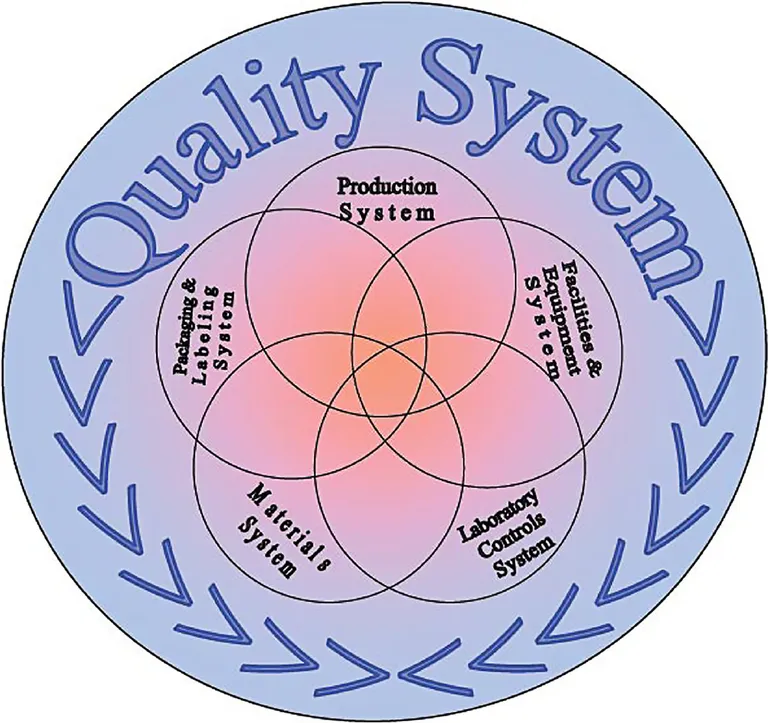

3 Pharmaceutical Quality System: A Newer Quality Trend

4 ICH Guidelines on QbD and Related Paradigms

5 Philosophy and Principles of QbD

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Contributors

- Preface

- Chapter 1: Introduction to Quality by Design (QbD): Fundamentals, Principles, and Applications

- Chapter 2: Global Regulatory Perspectives on Quality by Design in Pharma Manufacturing

- Chapter 3: Application of Design of Experiments (DoE) in Pharmaceutical Product and Process Optimization

- Chapter 4: QbD Considerations for Excipient Manufacturing

- Chapter 5: QbD Considerations for Analytical Development

- Chapter 6: Application of Quality by Design Paradigms for Development of Solid Dosage Forms

- Chapter 7: QbD Considerations for Topical and Transdermal Product Development

- Chapter 8: QbD-Based Development of Pharmaceutical Parenteral Drug Products: An Overview

- Chapter 9: Quality by Design Considerations for Product Development of Dry-Powder Inhalers

- Chapter 10: Quality by Design Considerations for the Development of Lyophilized Products

- Chapter 11: Application of Quality by Design Approach for Hot-Melt Extrusion Process Optimization

- Chapter 12: QbD Applications for the Development of Nanopharmaceutical Products

- Chapter 13: Application of QbD Principles in Nanocarrier-Based Drug Delivery Systems

- Chapter 14: Application of QbD Framework for Development of Self-Emulsifying Drug Delivery Systems

- Chapter 15: ‘Quality by Design’ Approach for Development of Multiparticulate Drug Delivery Systems

- Chapter 16: Application of QbD Elements for the Development of Conventional to Lipid Vesicular for Topical Drug Delivery System

- Chapter 17: Emergence of Quality by Design in Extraction Technology for Bioactive Compounds

- Chapter 18: Application of Quality by Design for the Development of Biopharmaceuticals

- Index

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app