eBook - ePub

Welding and Joining of Advanced High Strength Steels (AHSS)

- 204 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Welding and Joining of Advanced High Strength Steels (AHSS)

About this book

Welding and Joining of Advanced High Strength Steels (AHSS): The Automotive Industry discusses the ways advanced high strength steels (AHSS) are key to weight reduction in sectors such as automotive engineering. It includes a discussion on how welding can alter the microstructure in the heat affected zone, producing either excessive hardening or softening, and how these local changes create potential weaknesses that can lead to failure.

This text reviews the range of welding and other joining technologies for AHSS and how they can be best used to maximize the potential of AHSS.

- Reviews the properties and manufacturing techniques of advanced high strength steels (AHSS)

- Examines welding processes, performance, and fatigue in AHSS

- Focuses on AHSS welding and joining within the automotive industry

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Welding and Joining of Advanced High Strength Steels (AHSS) by Mahadev Shome,Muralidhar Tumuluru in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Construction & Architectural Engineering. We have over one million books available in our catalogue for you to explore.

Information

1

Introduction to welding and joining of advanced high-strength steels (AHSS)

M. Shome1, and M. Tumuluru2 1Research & Development, Tata Steel, Jamshedpur, India 2Research and Technology Center, United States Steel Corporation, Pittsburgh, PA, USA

Abstract

Advanced high-strength steels (AHSS) developed and commercialized in the past decade are designed to help automotive companies meet light-weight requirements without compromising occupant safety requirements. These steel grades are expected to dominate the material share in automobiles, especially in body-in-white applications, in the foreseeable future. These steels have an excellent combination of high strength and ductility, and hence are formable. AHSS grades require special considerations and an understanding of their welding behaviour for successful implementation in automotive construction. This chapter provides an overview of the common types of AHSS grades in current commercial use and the various joining techniques used in the automotive industry.

Keywords

Adhesive joining; Advanced high-strength steel (AHSS); Dual-phase steel; Gas metal arc welding; Laser welding; Mechanical fastening; Resistance spot welding; Transformation-induced plasticity steel1.1. Introduction

Fuel efficiency, lowering carbon emissions and passenger safety have been the main drivers in designing automobiles for the past two decades. Vehicle weight reduction was identified as a key strategy to minimize fuel consumption. For enhanced passenger safety, automotive structures that have a higher energy absorption in a crash situation would be ideal. Advanced high-strength steels (AHSSs) were developed to support these strategic requirements. A recent report from World Steel Dynamics projected that by 2025 the usage of AHSSs would reach 23.7 million tons. This means that a significant part of the low-carbon steel parts would be replaced by AHSSs (http://www.autosteel.org, report of October 4, 2014). Reductions in automotive mass and government regulations on crash requirements seem to have mutually opposing directions: fuel economy is ensured but safety can seemingly be endangered by lighter vehicles. However, studies to date using AHSSs for automobile designs have shown that reducing the weight of vehicles can be achieved without compromising passenger safety.

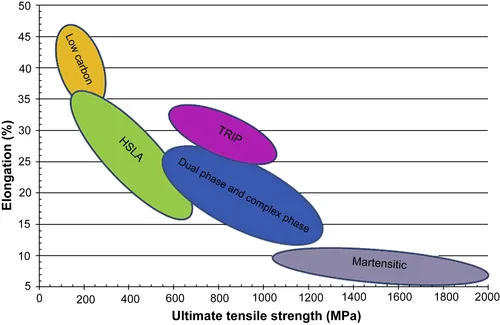

AHSSs are extensively used in the automobile industry for manufacturing several body-in-white parts of vehicles. Auto designers have introduced these steels in critical structural parts such as the A, B and C pillars; the roof rails and bow; cross-members; door beams; front and side members; and as bumper reinforcement. They also are extensively used in internal panels made of tailor-welded blanks. AHSSs exhibit ultimate tensile strengths of 600 MPa or higher, allowing vehicle manufacturers to make major strides in terms of the strength and rigidity of thinner-gauge sheets. In addition to high tensile properties these steels have good ductility, the capacity for high energy absorption and a high work-hardening coefficient over the uniform elongation regime. Dual-phase (DP), complex-phase (CP), transformation-induced plasticity (TRIP) and martensitic steels are the prevalent AHSS grades that are currently in commercial use. These grades are referred to as first-generation AHSSs. The relationship between the strength and ductility (as measured by elongation) of these steel grades is shown in Figure 1.1.

AHSS are multiphase steels that contain various concentrations of ferrite, bainite, martensite and retained austenite phases. The proportion of these phases and their morphologies are engineered to obtain the functional characteristics of a steel (Bhattacharya, 2011, p. 163; Davies, 2012; Galán, Samek, Verleysen, Verbeken, & Houbaert, 2012; Kuziak, Kawalla, & Waengler, 2008; Senuma, 2001). DP steels are commercially available from 500 to 1180 MPa, whereas TRIP and CP steels are available up to 980 MPa strength. These steel grades are used in applications that require high strength and high ductility (and hence good formability), as well as good weldability. Several studies have clearly shown the excellent weldability of these steel grades (Radakovic & Tumuluru, 2012; Sharma & Molian, 2011; Tumuluru, 2013). Some of the applications of these steels include B pillars and body inners. The microstructure of DP steels consists of ferrite and martensite, which provide the necessary strength and meets elongation requirements. Higher strength implies that there is a larger volume fraction of martensite in the steel. DP steels are used in both hot-rolled and cold-rolled conditions. Hot-rolled DP steel is mostly used for the structural parts and wheels of cars. Continuous yielding characteristics are a special feature of DP steels that ensures a smooth surface after the forming operation. TRIP steels contain ferrite, bainite and retained austenite phases. The retained austenite is transformed into martensite under a strain-induced deformation effect, absorbing significant amounts of energy; therefore TRIP steel is a designer’s choice for making crash-resistant components.

Figure 1.1 The strength versus elongation relationship for first-generation advanced high-strength steels. HSLA, high strength, low alloy; TRIP, transformation-induced plasticity.

Another category of AHSSs is martensitic steel. These steels are currently available with strength from 900 to 1900 MPa. The microstructure of these steels consists essentially of martensite. These steels are alloyed with carbon, manganese and chromium to achieve the required strength. Martensitic steels have high stiffness and anti-intrusion characteristics for passenger safety. Because of their higher carbon content—more than is contained in either DP or TRIP steels—martensitic steels are used in applications that generally do not require welding. Some examples of their application include door intrusion beams and bumpers.

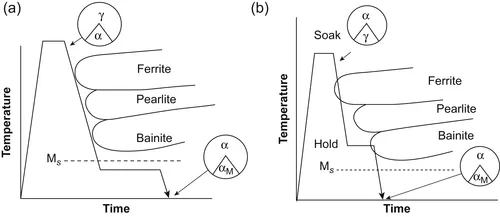

Cold-rolled DP and TRIP steels are processed in continuous annealing lines. Typical production methods for DP and TRIP steels are shown in Figure 1.2. For DP steel production, the cold-rolled, fully hard strip is subjected to intercritical (α + γ) annealing, followed by rapid cooling so that the austenite transforms into martensite. A uniform distribution of about 10% volume fraction of martensite in the ferrite matrix results in an excellent strength–ductility combination, low-yield strength–to–tensile strength ratio and a high work-hardening index. TRIP steels are produced by applying a two-stage heat treatment process. The cold-rolled sheets are heated to the intercritical temperature and held there for a short time, allowing austenite to form. The annealing temperature and time determine the austenite volume fraction and carbon concentration. In the second stage the coils are rapidly cooled and isothermally held at a temperature at which a bainitic reaction occurs. The carbon rejected during the bainitic transformation enriches the remaining austenite and stabilizes it. For galvanized and galvannealed steels, the same heat treatment concept is followed. For coating purposes, the sheets are cooled from the intercritical temperature and passed through a galvanizing bath kept at 460 °C (Liu et al., 2012). The silicon content in AHSSs is kept very low to avoid adhesion problems in galvanizing baths. Strength improvements for coated AHSSs are achieved through alloying with elements such as manganese and chromium.

Figure 1.2 Typical production methods for dual-phase (a) and transformation-induced plasticity steels (b).

While these steels have a combination of superior mechanical properties, their application in terms of forming and welding requires a different approach than the one used for low-carbon steels. During welding, the heat produced alters the microstructure of the base material and therefore the mechanical properties. The heating and cooling rates are extremely rapid in all welding processes during automotive body manufacturing. The peak temperature observed in the fusion zone (FZ) is above the melting point of steel and is somewhat lower in the heat-affected zone (HAZ). In the HAZ there is significant austenite grain growth followed by phase transformation; consequently, the microstructure formed is different from that of the base metal. The task, therefore, is to control the thermal conditions by applying appropriate welding parameters. Solid-state welding and alternative joining techniques have recently been tested to preserve the functional properties of AHSSs without worrying much about temperature-related damage to the microstructure caused by conventional welding.

Welding is an integral part of automobile manufacturing and is carried out through various processes. There are advantages and disadvantages of each process. An overview of the most common processes with respect to welding and joining AHSSs are briefly discussed.

1.2. Overview of major welding processes for AHSS

1.2.1. Resistance spot welding

DP steels are easily weldable and have been commercially implemented in current automotive designs (Radakovic & Tumuluru, 2012). The typical requirement for spot welds is to have a minimum load-bearing capacity equivalent to or greater than that of the base metal. The load capacity formula includes the thickness of the sheet, the weld nugget diameter and the ultimate tensile strength of the steel (Radakovic & Tumuluru, 2008, 2012). The nugget diameter depends on the welding parameters and is critical for AHSS because it largely controls the type of weld failure under quasi-static and dynamic loading conditions.

Spot welds can fail in any of the following three modes: interfacial failure, in which the fracture propagates through the nugget; pull-out failure, in which the weld nugget separates from the parent metal; and partial interfacial failure, in which the fracture initially propagates through the nugget and then deviates through the sheet thickness, similar to pull-out failure. Pull-out failure is preferred because it is associated with high-load bearing capacity and high energy absorption. Recent work has shown that interfacial fractures are the expected mode in AHSSs and that welds that fail with the interfacial fracture mode have a load-bearing ability that is 90% of welds that fail with a pull-out mode (Radakovic & Tumuluru, 2008; Tumuluru, 2006b).

Work done on the entire range of DP steels of 590-, 780- and 980-MPa strength shows a certain pattern of nugget failure during shear tensile tests. Full-button pull-out fracture occurs when the weld nugget size is large, and interfacial fracture occurs when the nuggets are small (Tumuluru, 2008; Radakovic & Tumuluru, ...

Table of contents

- Cover image

- Title page

- Table of Contents

- Related titles

- Copyright

- List of contributors

- Woodhead Publishing Series in Welding and Other Joining Technologies

- 1. Introduction to welding and joining of advanced high-strength steels (AHSS)

- 2. Properties and automotive applications of advanced high-strength steels (AHSS)

- 3. Manufacturing of advanced high-strength steels (AHSS)

- 4. Resistance spot welding techniques for advanced high-strength steels (AHSS)

- 5. Laser welding of advanced high-strength steels (AHSS)

- 6. High-power beam welding of advanced high-strength steels (AHSS)

- 7. Hybrid welding processes in advanced high-strength steels (AHSS)

- 8. Metal inert gas (MIG) brazing and friction stir spot welding of advanced high-strength steels (AHSS)

- 9. Adhesive bonding techniques for advanced high-strength steels (AHSS)

- 10. Mechanical fastening techniques for advanced high-strength steels (AHSS)

- Index