- 126 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

Sustainability enables the development of products with minimal environment impact coupled with economical and societal benefits. This book provides an understanding of theoretical and practical perspectives pertaining to Sustainable manufacturing.

This book focuses on fundamentals, providing insights, concepts, tools, methods, case studies, and practical perspectives taken from research.

The book will be of interest to students, researchers and industry practitioners.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Sustainable Manufacturing by S. Vinodh in PDF and/or ePUB format, as well as other popular books in Design & Operazioni. We have over one million books available in our catalogue for you to explore.

Information

1

Concepts and Fundamentals of Sustainable Manufacturing, Triple Bottom Line Approach

1.1 Overview of Triple Bottom Line

Triple bottom line (TBL) is the base for sustainability. TBL underlies the rationale of sustainability by evaluating the impact in terms of profitability; shareholder values; and its societal, people and environmental capital (Savitz, 2013). It is based on 3Ps: profitability, people and planet. Profitability pertains to the economy; people pertain to societal and planet pertains to environmental dimensions. It considers the development and application of a corporate strategy involving environmental, societal and financial results (Mowat, 2002). TBL provides a three-dimensional view of sustainability moving from the viewpoint of the environment to include economic and societal dimensions (Shaffer, 2018). Widely cited definitions of TBL are presented in Table 1.1.

TABLE 1.1

Widely Cited Definitions of TBL

Widely Cited Definitions of TBL

Definition | Reference |

‘Taking environmental, social and financial results into consideration in the development and implementation of a corporate business strategy’. | Mowat (2002) |

TBL firms aim to become more responsive ecologically and socially while prospering economically. This threefold focus is often referred to in terms of ‘people, planet, profit’, or as the ‘‘triple bottom line’ (TBL). | Elkington (1997) |

1.2 Overview of Sustainable Manufacturing with Evolutionary Aspects

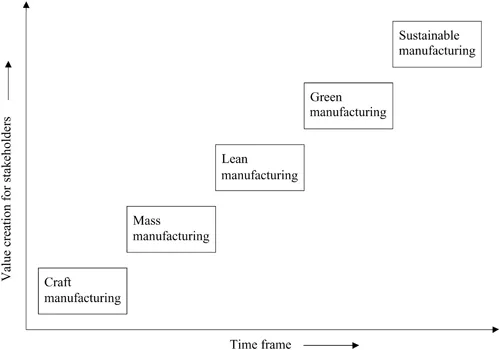

Manufacturing systems have witnessed a shift from mass production to lean, green and sustainable manufacturing. The transition of manufacturing systems is shown in Figure 1.1. Key parameters governing this transition include product complexity, market dynamism and stakeholder value. Craft manufacturing includes skilled employees and has low production volume. Mass manufacturing is characterized by interchangeable parts and delivers high productivity (Rojko, 2017). It can handle market dynamism better than a craft system. Mass manufacturing is characterized by high-volume manufacturing with limited product variants. It fulfils economies of scale, which state that the unit cost of a product comes down as a result of high-volume production. Lean manufacturing is characterized by waste elimination, streamlined processes and value addition (de Freitas et al., 2017). Lean is a predecessor manufacturing system to green and sustainable manufacturing. Lean production is based on the Toyota Production System (TPS), which is waste reduction based on skilled workers and focused on value addition. Green manufacturing is environmentally benign and 3R-based (reduce, reuse, recycle). Sustainable manufacturing is innovative and 6R-based (3Rs plus recovery, redesign and remanufacture). Sustainable manufacturing is referred to as an ‘E’ paradigm with the focus on ecology, economy, excellence and so on. Lean is a predecessor element to sustainability as lean facilitates waste elimination, which forms the path for sustainable manufacturing.

Transition of manufacturing systems.

Sustainable manufacturing (SM) is concerned with executing a new form of business with value creation to develop green products and processes in demand (Alayón, 2016). Key business benefits from SM include improvement of efficiency and productivity, reduced usage of hazardous materials, compliance with regulations, enhanced reputation and enhanced community relations.

The environmental focus of manufacturing was initially on pollution abatement (reducing pollution). Then the shift was towards cleaner production and pollution prevention (U.S. Department of Commerce, 2011).

1.2.1 Evolution of Sustainable Manufacturing

The main environmental focus in a manufacturing context had been referred to as pollution abatement, that is preventing the pollution generated from entering the environment. Then the focus became cleaner production and pollution prevention. With cleaner production, there exists scope for cost reduction and other economic advantages (U.S. Department of Commerce, 2011).

- Clean technologies are vital from the viewpoint of sustainable manufacturing and include associated aspects such as environmental protection, compliance with regulatory bodies, pollution prevention and renewable technologies.

- Green production deals with development of green products, i.e. products with minimal environmental impact.

- Sustainable manufacturing includes a methodological approach for waste elimination by resource optimization and utilization of resources, and technologies with less environmental impact.

1.3 Definitions of Sustainable Manufacturing

Widely cited definitions of sustainable manufacturing are presented in Table 1.2. Elements identified with sustainable manufacturing include fewer environmental impacts, resources conservation, safety, economic benefits, meeting requirements of future generations, energy conservation, employee health, inclusive growth and optimal resource utilization. SM facilitates the development of green products that are designed to reduce environmental impact with the usage of recyclable materials.

TABLE 1.2

Widely Cited Definitions of Sustainable Manufacturing

Widely Cited Definitions of Sustainable Manufacturing

Definition | Reference |

‘Manufacturing processes that meet the needs of the present without compromising future generations’ ability to meet their own needs’. | Gardner and Colwill (2016) |

‘The creation of manufactured products that use processes that minimize negative environmental impacts, conserve energy and natural resources, are safe for employees, communities, and consumers; and are economically sound’. | U.S. Department of Commerce (2011) |

1.3.1 Business Benefits of SM are (Alayon, 2016)

- Increased sales.

- Improved efficiency and productivity.

- Compliance with regulations.

- Enhanced reputation and image.

- Better community relations (Alayón, 2016).

1.3.2 Implementation of Sustainable Manufacturing at Initial Stage

The details of implementing SM are presented as follows (U.S. Department of Commerce, 2011; Kishawy et al., 2018):

- Housekeeping – Can be facilitated with 5S lean tools for enhancement in work practices.

- Process optimi...

Table of contents

- Cover

- Half-Title

- Title

- Copyright

- Dedication

- Contents

- Preface

- Acknowledgements

- Author

- 1. Concepts and Fundamentals of Sustainable Manufacturing, Triple Bottom Line Approach

- 2. Sustainable Manufacturing Tools: Environmentally Conscious Quality Function Deployment (ECQFD)

- 3. Sustainable Manufacturing Tools: Life Cycle Assessment (LCA)

- 4. Life Cycle Impact Assessment Methods: CML, Eco-Indicator 95 and Eco-Indicator 99

- 5. Design Strategies Supporting Sustainable Manufacturing

- 6. Standards for Sustainable Manufacturing

- 7. Product Sustainability and Risk–Benefit Assessment, and Corporate Social Responsibility

- 8. Sustainability Assessment

- 9. Software Modules for Life Cycle Assessment (LCA) and Sustainable Manufacturing

- 10. Sustainability and Energy Aspects of Manufacturing Processes

- 11. Case Studies on ECQFD, LCA and MCDM

- 12. Research Issues in Sustainable Manufacturing

- Index