Industry 4.0 – Shaping The Future of The Digital World

Proceedings of the 2nd International Conference on Sustainable Smart Manufacturing (S2M 2019), 9–11 April 2019, Manchester, UK

- 356 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Industry 4.0 – Shaping The Future of The Digital World

Proceedings of the 2nd International Conference on Sustainable Smart Manufacturing (S2M 2019), 9–11 April 2019, Manchester, UK

About this book

The City of Manchester, once the birthplace of the 1st Industrial Revolution, is today a pioneering hub of the 4th Industrial Revolution (Industry 4.0), offering Industry 4.0 solutions in advanced materials, engineering, healthcare and social sciences. Indeed, the creation of some of the city's greatest academic institutions was a direct outcome of the industrial revolution, so it was something of a homecoming that the Sustainable Smart Manufacturing (S2M) Conference was hosted by The University of Manchester in 2019.

The conference was jointly organised by The University of Manchester, The University of Lisbon and The Polytechnic of Leiria – the latter two bringing in a wealth of expertise in how Industry 4.0 manifests itself in the context of sustainably evolving, deeply-rooted cities.

S2M-2019 instigated the development of 61 papers selected for publication in this book on areas of Smart Manufacturing, Additive Manufacturing and Virtual Prototyping, Materials for Healthcare Applications and Circular Economy, Design Education, and Urban Spaces.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

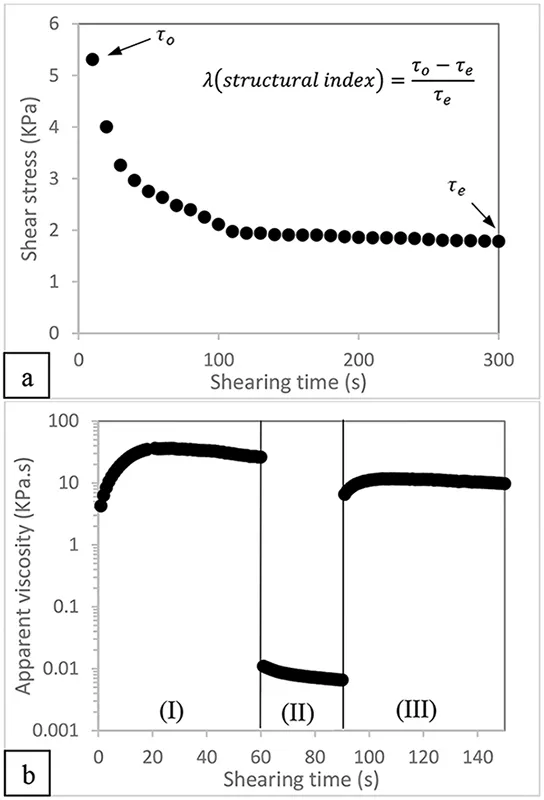

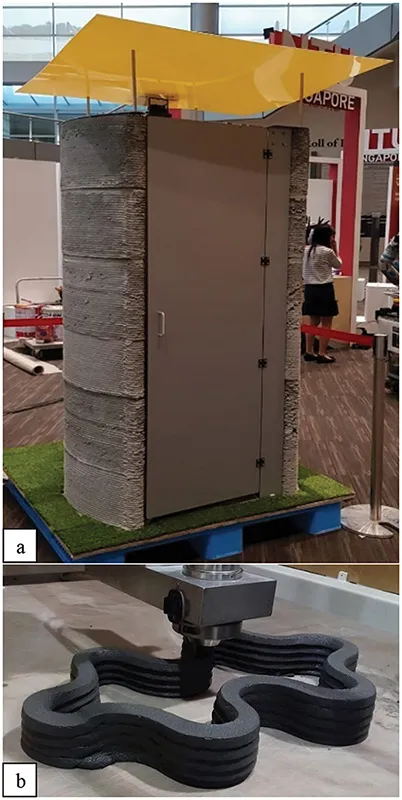

Additive manufacturing and virtual prototyping

3D printing for sustainable construction

1 INTRODUCTION

1.1 3D concrete printing and printable material

1.2 Sustainable construction

2 SUSTAINABLE PRINTABLE MATERIALS

2.1 High volume fly ash concrete

2.2 Geopolymers

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Table of Contents

- Preface

- Committee members

- Keynote speaker

- International scientific committee

- Smart manufacturing

- Additive manufacturing and virtual prototyping

- Materials for healthcare applications and circular economy

- Design education

- Urban spaces

- Author Index