- 392 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

Pipeline and Energy Plant Piping: Design and Technology covers the proceedings of an international conference, "Pipeline and Energy Plant Piping – Fabrication in the 80's. The book covers the total spectrum of technology relevant to pipeline fabrication, design, materials, welding process, inspection, defect acceptance, performance, and project management. The text also discusses other energy systems, such as nuclear, hydroelectric, oil, and gas transmission, to understand the technological demands of energy production and distribution. The text will be of great interest to professionals such as engineers whose line of work involves the management and regulation of piping systems.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Pipeline and Energy Plant Piping by Sam Stuart in PDF and/or ePUB format, as well as other popular books in Tecnología e ingeniería & Ingeniería mecánica. We have over one million books available in our catalogue for you to explore.

Information

Managing the Construction of the Alaska Highway Gas Pipeline Project

R.B. Snyder, Alberta Gas Trunk Line, Alaska Project Division Calgary, Alberta

Publisher Summary

The Alaska Highway Gas Pipeline has been described as the largest privately financed project ever undertaken. This chapter focuses on the management of the construction of this project. The total Alaska Highway Gas Pipeline project is broken down into four major segments, each handled by a separate project team formed with the expertise needed to handle the characteristics of the particular geographic portion with which they are involved. The sponsors of the Canadian portion of the Project, Alberta Gas Trunk Line, and Westcoast Transmission are large operating companies. A pipeline project like any other major project is comprised of a number of modules. Such modules can be worked on by individual design and construction teams. In the case of a pipeline, the modules are the compressor stations and pipeline spread sections. With construction spread over six years, a reasonable loading of the Canadian pipeline construction industry can be achieved. No more than five pipeline spreads are planned to be under way at one time. While the bulk of the compressor stations will be built over the same three-year period, the stations will be constructed by relatively small work groups located in several different jurisdictions.

The Alaska Highway Gas Pipeline has been described as the largest privately financed project ever undertaken. The project is indeed large and currently quoted in the media as having a price tag of $21.7 billion. Such figures are unofficial and include the Prudhoe Bay gathering system and processing plant which have been designated by the U.S. Federal Energy Regulatory Commission as the responsibility of the North Slope producers. While large, the project is, however, basically a pipeline of a type common to the North American construction scene. It does have some unique technical aspects in the area of frost heave and pipe metallurgy, but by far the majority of the technical elements of the project embrace well established proven concepts.

Again, while large, the project is not a single monolithic entity, the construction of which will demand superhuman efforts to keep it under control. The overall project breaks down nicely into readily manageable packages which a strong management team with well planned project procedures and responsive, timely information systems can control through to on time, on budget completion.

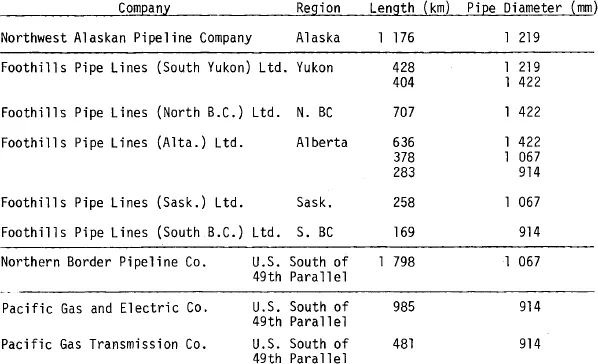

The companies responsible for and actively directing the construction of the pipeline portions of this major gas transportation system are formed into four groups as shown in Table 1. Northwest Alaskan is sponsored by seven U.S. pipeline companies and Northern Border Pipeline by four U.S. and one Canadian pipeline company.

TABLE 1

The Alaska Highway Natural Gas Pipeline Project Sections

Overall, then the total project is broken down into four major segments, each handled by a separate project team formed with the expertise needed to handle the characteristics of the particular geographic portion with which they are involved.

The sponsors of the Canadian portion of the Project, Alberta Gas Trunk Line and Westcoast Transmission are large operating companies. At the end of 1979 these companies had combined assets of $4.2 billion (Canadian) and operated 13 129 km of natural gas transmission lines of up to 1 067 mm in diameter. The U.S. pipeline sponsors of the U.S. section, in 1978, the most recent data available, had assets of 18.8 billion U.S. dollars and together they operated 194 407 km of pipelines. All of the experience and capability of these companies is available to the project teams managing the Alaska Highway Pipeline Project.

The Canadian portion of the project, estimated to cost $8.4 billion (Canadian) in escalated dollars is similarly divided into five manageable sized sections. As well the project will be constructed in phases, an early “prebuild” phase to provide an early cash flow through the transportation of surplus Canadian gas available for export and a later mainline phase when the balance of the pipeline to carry Alaska Gas will be constructed. The combined phases will span six years with the complete project in service in late 1985.

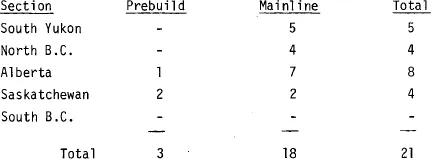

A pipeline project like any other major project is comprized of a number of modules. Such modules can be worked on by individual design and construction teams. In the case of a pipeline the modules are the compressor stations and pipeline spread sections. For practical, detailed planning and construction management purposes each of these can be addressed individually. Our project will require 21 compressor stations to be in place by 1985. See Table 2.

TABLE 2

Compressor Stations

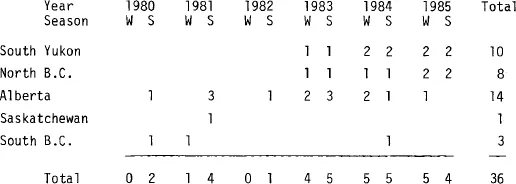

Plans for construction of the pipe portion of the line call for the Canadian sections to be built in 36 sections or spreads. See Table 3. In Canada, therefore, the Alaska Highway Pipeline will be constructed of 57 modules, each of a size and scope common to the construction industry in North America.

TABLE 3

Spread Allocation

With construction spread over six years a reasonable loading of the Canadian pipeline construction industry can be achieved. No more than five pipeline spreads are planned to be under way at one time. While the bulk of the compressor stations will be built over the same three year period, the stations will be constructed by relatively small work groups located in several different jurisdictions. This construction plan has been carefully tailored to fit the Canadian construction scene, to maximize the use of Canadian workers and contractors, and to reflect the trades availabilities as they actually are in Western Canada.

The first step then, in managing this major pipeline project, has been to recognize its natural geographical components and construction modules, to focus planning on them and to structure the required management organization and systems around them.

The second step was to select and develop the organization and systems required to effectively manage the project. Because of the large dollar figures involved in the project, because its construction spans six years in a period of inflation and high cost of money, because of the high public profile of the project and because it will be constructed under a unique regulatory framework, practical and timely information, accounting and scheduling systems perhaps not used previously on pipeline projects, will be required.

Information will be required on two levels: a detailed level for the day to day control of project activities by the construction management team, and at a summary level for the executive management of the project, for financing purposes and for regulatory reporting. All information must be captured and processed into usable report form in a timely manner, if it is to be put to effective use to meet the company’s objectives.

Detailed planning for the project has been underway since July, 1977 when the National Energy Board approved the Company’s application to construct on the Alaska Highway route. Currently a team of 350 people based in Calgary is continuing with the work needed for the Prebuild phase with actual construction planned to start this summer. This work force is divided about equally between Foothills (Yukon) and the Alaska Project Division, who are handling the design and construction management of the Prebuild sections in Alberta and Saskatchewan. The smaller southeastern B.C. section is being designed and managed by Alberta Natural Gas.

In preparation for the Prebuild phase, systems development at the summary or project overview level is being carried forward by the Foothills (Yukon) parent company team. At the detailed level, the needed systems have been selected and implemented by the Alaska Project Division of Alberta Gas Trunk Line. Close cooperation by the two teams has ensured that all necessary data can readily be supplied at the system interfaces.

Where possible existing software packages have been selected and purchased to minimize systems development costs and lead time. The purchased packages are installed and brought on line by the combined efforts of the systems staff of Alberta Gas Trunk Line and Foothills (Yukon). To date all computer hardware requirements of the project are being met by the Alberta Gas Trunk Line Amhdahl V 5 installation located in Calgary.

Although the subdivision of the project by section and module makes good sense from a practical management viewpoint, such an approach brings with it a need for close coordination. Close control of the numerous component activities and approvals is most important. A computer based scheduling system has been installed to assist in the control of the many items that need to be tracked and to provide the quick reporting turn around demanded by the project team.

To facilitate construction of the project and ensure that maximum benefits for Canadians are secured, the Canadian government passed the Northern Pipeline Act and established the Northern Pipeline Agency. The Agency administers the Act and the more detailed Terms and Conditions established thereunder. As well, the project is under the watchful eye of the National Energy Board and special senate and House of Commons subcommittees. This unique regulatory structure requires a more extensive number of approvals, a more detailed level of documentation, and a more elaborate system of reporting than previously required for an energy project in Canada. The companies have established their regulatory affairs and project control functions accordingly to meet these requirements.

Two elements of the regulatory framework existing for the project impose more extensive than normal data gathering and reporting requirements on the project. These are, first, the more extensive advance regulatory review and approval authority given to the Northern Pipeline Agency which in turn requires a level of documentation far greater than usual for a pipeline project. Secondly, the Incentive Rate of Return scheme under which the project is being constructed, will lead to exceptionally thorough review of all project costs. Good management, therefore, demands that extensive documentation be assembled during construction in preparation for that review.

A further division of the responsibility for managing the project is in the acquisition of the more important material and equipment components. The purchase of the major material items required for the Canadian sections is being handled on a centralized basis by Foothills (Yukon). The major items of material and equipment, or “designated items” as referred to by the Agency, must be obtained in conformance with a set of guidelines that stress the importance of Canadian content and maximizing the long term industrial benefits to Canada that can flow from such purchases.

On April 29, 1980, Foothills (Yukon) announced that negotiations with The Steel Company of Canada and Interprovincial Steel and Pipe Corporation Ltd. had been concluded for the line pipe neede...

Table of contents

- Cover image

- Title page

- Table of Contents

- PERGAMON TITLES OF RELATED INTEREST

- Copyright

- Foreword

- Chapter 1: Managing the Construction of the Alaska Highway Gas Pipeline Project

- Chapter 2: Piping for Power and Other Industries in a Developing Country — India

- Chapter 3: Cold Lake High Pressure Steam Distribution System

- Chapter 4: Line Pipe Research in the Canadian Federal Government

- Chapter 5: High Toughness Line Pipe for Arctic Use

- Chapter 6: Design Technology, Production and Principal Features of Multilayer Pipes for Trunk Gas Pipelines

- Chapter 7: Properties of High Strength, Titanium Bearing Steel for Large Diameter Pipeline

- Chapter 8: Embrittlement of Plateformed SA515 GR. 70 Fusion Welded Pipes for High Temperature Service

- Chapter 9: Weld Cold Cracking and Sulfide Stress Corrosion Cracking in Arctic Grade Line Pipe

- Chapter 10: Toughness of Submerged Arc Welds in Large Diameter Grade 70 Line Pipe

- Chapter 11: Properties of Weldments for Pipeline Applications

- Chapter 12: Recent Developments in Welding Materials for High Performance Arctic Grade Line Pipe Production

- Chapter 13: Productivity Factors in Submerged Arc Line Pipe Welding Applications

- Chapter 14: The Effects of Nickel and Titanium on Submerged Arc Welds in HSLA Steels

- Chapter 15: Peculiarities of Welding High Strength Large Diameter Line Pipe Steels with Cellulose- and Low Hydrogen Type Electrodes

- Chapter 16: A Low Hydrogen Type Electrode for Girth Welding of Linepipes

- Chapter 17: New Opportunities to Improve Quality and Productivity by Low-Hydrogen Pipewelding

- Chapter 18: Line Pipe Welding with Innershield

- Chapter 19: Welding Automation in the Ontario Hydro Nuclear Power Program

- Chapter 20: The Serimer’s “Saturne” Automatic Pipeline Welding System for Off-Shore and On-Shore

- Chapter 21: Automatic Welding of Pipelines

- Chapter 22: Advances in Pipe Welding

- Chapter 23: Resistance Flash Butt Welding of Pipelines

- Chapter 24: High Impact Welding

- Chapter 25: The Influence of REM Treatment of Steel on Some Aspects of Weldability When Using the Stovepipe Welding Technique for Line Pipe Girth Welds

- Chapter 26: Effect of Microalloying on Weld Cracking in Low Carbon Steels

- Chapter 27: Underbead Cracking in High Strength Pipe Steels

- Chapter 28: Root Pass Stresses in Pipeline Girth Welds Due To Lifting

- Chapter 29: Automatic Data Recording During Manual Ultrasonic Inspection

- Chapter 30: Automatic Ultrasonic Apparatus Developed for Periodic Inspection of the High Pressure Hydraulic System at Dinorwic Power Station

- Chapter 31: Precise Ultrasonic Depth Measurements of Internal Undercut in Pipeline Girth Welds

- Chapter 32: AECL Research and Development in Piping System Nondestructive Testing

- Chapter 33: Ultrasonic Monitoring of Growth of Part-Through Thickness Defects in Pipes at 290° C

- Chapter 34: Alternative Girth Weld Defect Assessment Criteria for Pipelines

- Chapter 35: Interim Report on the Significance of Blunt Flaws in Pipeline Girth Welds

- Chapter 36: Ductile Fracture Propagation in Pipelines: Bursting Full-Scale Tests on 48″ and 56″ Diameter Pipes for Gas Transmission

- Chapter 37: Fabrication and Operational Aspects of the Northern Alberta Burst Testing Facility

- Chapter 38: Full Scale Testing of Large Diameter Pipelines

- Chapter 39: Testing Factors Which Influence Fatigue Life of Butt Welded Low Carbon Steels

- Keyword Index