Solid/Liquid Separation

Scale-up of Industrial Equipment

- 454 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

About this book

This book identifies test procedures used within sectors of the solid/liquid separation equipment industry, providing practical explanations for test data and their uses when faced with a new application to assess. With a strong practical emphasis, this book is ideal for use as a reference text for engineers concerned with applications evaluation of equipment or its scale-up. This book forms part of a five-volume set on all aspects of filtration and separation processes. One other volume is currently available from the set: Wakeman & Tarleton: Solid/Liquid Separation: Principles of Industrial Filtration.This book...•Provides guidance on how to tackle practical solid/liquid separation problems in an industrial setting•Shows how to plan, conduct and interpret experiments•Details test procedures, types of tests and how to interpret results when assessing a new application•Strong emphasis on current industrial practice•Provides a practical account which will help lead to the best use of appropriate equipment yielding optimal results·Provides guidance on how to tackle practical solid/liquid separation problems in an industrial setting·Shows how to plan, conduct and interpret experiments·Details test procedures, types of tests and how to interpret results when assessing a new application·Strong emphasis on current industrial practice·Provides a practical account which will help lead to the best use of appropriate equipment yielding optimal results

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

Solid/liquid separation equipment selection

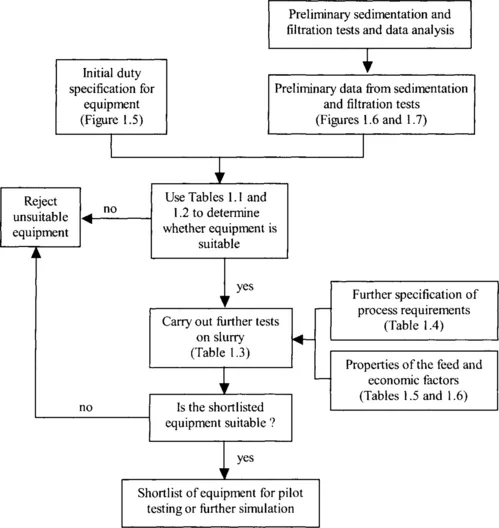

1.1 Methods of equipment selection

1.2 Test procedures

1.2.1 Jar sedimentation tests

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Preface

- List of Contributors

- Chapter 1: Solid/liquid separation equipment selection

- Chapter 2: Chemical pre-treatment

- Chapter 3: Deep bed filters

- Chapter 4: Membrane filters – microfiltration and ultrafiltration

- Chapter 5: Pressure filters

- Chapter 6: Vacuum filters

- Chapter 7: Filtering centrifuges

- Chapter 8: Sedimenting centrifuges

- Index