eBook - ePub

Rethinking Bhopal

A Definitive Guide to Investigating, Preventing, and Learning from Industrial Disasters

- 510 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Rethinking Bhopal

A Definitive Guide to Investigating, Preventing, and Learning from Industrial Disasters

About this book

Rethinking Bhopal: A Definitive Guide to Investigating, Preventing, and Learning from Industrial Disasters is the go-to source for anyone seeking to learn how to improve process safety management (PSM) through applying fundamental asset reliability and incident investigation concepts.

The seeds that unified PSM on a global scale were planted in Bhopal, India on December 3, 1984. Since then, considerable progress has been made to protect both workers and communities from catastrophic industrial failures. Industry acknowledges its responsibility to create value with accrued operating experience and that using information received from previous failures is a direct way to prevent future incidents. With this principle in mind, Bloch evaluates modern references related to the Bhopal Disaster, using recognized industrial asset reliability and incident investigation concepts.

The practice of objective incident investigation offers a compelling insight into specific decisions and actions that resulted in history's worst industrial disaster. Recording a fully transparent sequence of events promotes a personal sense of accountability for anyone involved in the manufacturing industry. Lessons learned can be immediately implemented by those with direct PSM, management, engineering, and operating responsibilities. Case histories demonstrate how patterns observed in the timeline leading up to the Bhopal Disaster can be detected in modern incidents and by recognizing these patterns in present-day processes avoids counterproductive operating decisions and unprecedented destruction.

This text is instrumental in helping existing organizations re-evaluate their own exposures and risks, and would be a valuable read for any member of a process safety management team. Rethinking Bhopal: A Definitive Guide to Investigating, Preventing, and Learning from Industrial Disasters provides an expansion of knowledge and understanding for the novice in PSM while also providing depth and application considerations to challenge more experienced industry professionals. Note: All royalties from this book go to the Process Safety Heritage Trust Scholarship at Lamar University in Beaumont, Texas, USA.

- Learn how to improve Process Safety Management (PSM) performance by applying fundamental asset reliability and incident investigation concepts

- Understand your personal role in detecting and preventing Loss of Primary Containment (LOPC) incidents before they occur

- Take immediate action to stabilize processes under your control while promoting a systematic approach to eliminating persistent failure mechanisms

- Includes case histories to helpfully illustrate how to detect potentially destructive patterns in your own organization

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Rethinking Bhopal by Kenneth Bloch in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Insurance. We have over one million books available in our catalogue for you to explore.

Information

Part 1

Process Reliability

Chapter 1

Industrial Learning Processes

Abstract

The Bhopal disaster is regarded as history’s worst industrial accident. The disaster shaped the way that modern industry operates today. Although significant improvements were instituted after the disaster, catastrophic process releases are still a regular occurrence throughout the manufacturing industry worldwide. These incidents are reminders that process safety management is an ongoing program that has yet to become sustainable. Commendable changes are then introduced by both regulatory agencies and industry; their aim is to promote safe production in response to more recent incidents. However, incident prevention is by far the most effective and desirable option for managing process hazards; it ranks well ahead of postincident analysis. A thoroughly experience-based analysis of the Bhopal disaster provides a case study that demonstrates the importance of using a systematic approach to diagnosing process reliability issues. Our use of the term “issues” here is quite deliberate and reasoned. All process reliability issues could, if not properly addressed, complicate factory operation. Industrial disasters can be prevented by avoiding unnecessary complexities.

Keywords

Bhopal disaster; Case study; Failure analysis; Incident prevention; Industrial accident; Investigation; Process optimization; Process release; Process safety management; PSMThe manufacturing industry is the backbone of the world’s commercial system. Its purpose is to provide an adequate supply of useful products that consumers are inclined to purchase. Industry thrives by generating economic wealth for investors while improving the standard of living for people around the world. Generating this wealth and making its fruitage both available and affordable is the perfect example of a win–win situation that rewards both consumers and those who are willing to accept manufacturing responsibilities.

If industry’s goal is to offer security and comfort to the public through the development of useful products, then nothing could have defeated that mission more completely than the Bhopal disaster. This major incident occurred in a relatively small factory that had operated rather anonymously in central India up until December 3, 1984. The Bhopal disaster made an unparalleled impression and left questions for modern industry that have persisted for decades. This is one of the reasons why the Bhopal disaster is considered history’s worst industrial accident. A brief overview of the circumstances behind the Bhopal disaster is appropriate for a number of reasons; however, recognizing the full value of thoroughly and authoritatively analyzing the event ranks first and foremost among these reasons. Knowing and fully understanding the circumstances will serve as an indelible case study for people with the responsibility to protect the lives of others both directly and indirectly.

The Bhopal Disaster

The international subsidiary of an American multinational chemical company commissioned a full-conversion pesticide manufacturing process in Bhopal, India, in 1979 [1]. The manufacturing process consisted of using raw materials to generate intermediate products that were then fed to a reactor to make the final product. One of the intermediate products was a reactive, toxic, volatile, and flammable derivative of phosgene [2]. Its flammability and toxicity hazards made it unsuitable for discharge into the environment [3]. A lethal dose could realistically develop upon its release into the atmosphere. Process containment, therefore, was highly important under both normal and emergency operating conditions. Accordingly, safe design and operating practices were initially incorporated and implemented; they embodied the commendable goal of maintaining adequate process control at all times.

The exposure hazards associated with the toxic intermediate were well known. In its vaporized form, the toxic intermediate was a serious health hazard. Breathing it in could result in a fatal lung injury [4]. However, contact by any means was not recommended.

With the unforgiving process in mind, it was somewhat comforting to know that the business was in good hands. The parent company was one of the most trusted, innovative, experienced, successful, and respected organizations in the chemical manufacturing industry at the time. For over a decade the same manufacturing process had been safely generating the toxic intermediate compound in a domestic factory in the United States. That process served as the design template for the overseas factory in India. On the basis of accrued design and operating experience, it was reasonable to expect that the overseas manufacturing operation (the Bhopal factory) would be at least as safe as the existing domestic production site in the United States [14].

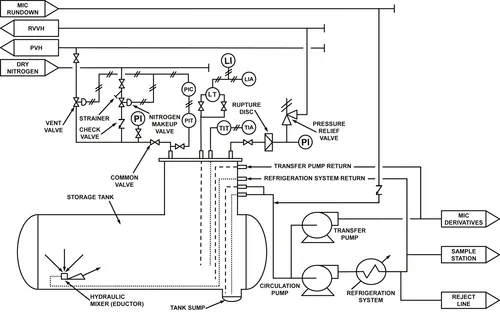

Routine maintenance was taking place in the Bhopal factory on the evening of December 2, 1984. The toxic intermediate compound was contained in three stainless-steel storage tanks (Fig. 1.1) according to normal procedures. An exothermic reaction could result if the tank contents were contaminated by an incompatible substance, which included water. If not detected, this adverse operating condition could propagate into a thermal runaway reaction which could realistically result in a catastrophic process release. That is why special provisions were included by design to keep contaminants out of the storage tanks. Safety systems were also provided to manage the chemical reactivity hazard if the tank contents should somehow become contaminated.

Shortly before midnight, factory workers noticed a stinging sensation in their eyes and throats [8]. Under suspicion that the process might be leaking somewhere, they started checking the pipes. The workers soon located gas and water escaping from an overhead vapor line and immediately took steps to address the problem [9–12]. It was unclear to them whether or not the leak signified another problem elsewhere in the factory. Process leaks were a common occurrence within the factory site [13]. Up to this point, all of the gauges that would indicate a problem inside the storage tanks were reading within their normal ranges.

Following standard protocol, the workers reported what they had found to the control room [14]. This prompted a worker at the control panel to take another look at the storage tank pressure gauges. This time, he noticed that one of the three storage tanks’ pressure gauges was now reading higher than normal [15]. Although this immediately drew the workers’ attention to the contaminated tank, it was already too late. Water had been contaminating the tank for about 2 h. An exothermic chemical reaction was already in full progress and the tank contents were hot [16]. The workers took immediate steps to control the unstable condition, but the situation continued to deteriorate rapidly. Not long after that, the pressure inside the tank exceeded the pressure relief system’s set point. At that very moment hot, boiling, lethal process vapor and liquid charged into the tank’s vapor management system [17].

Figure 1.1 Intermediate storage tank [5–7].

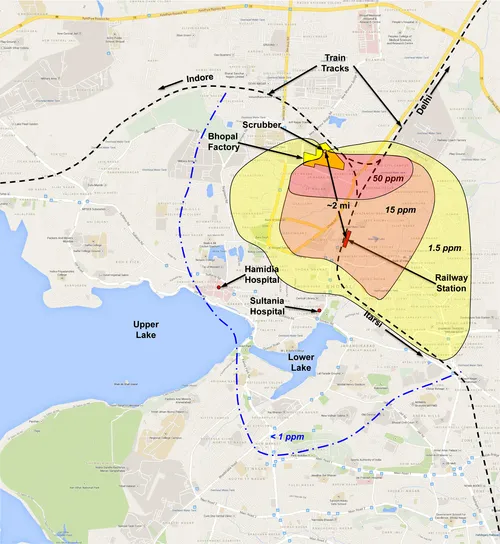

The unstable tank contents now surged into a process vapor scrubbing system that was specially designed to neutralize any material entering it. The scrubbing system proved unable to cope with the high-volume process influent and, with nowhere else to go, about 28 tons of the toxic intermediate chemical vapor was discharged directly into the sky above Bhopal. The release lasted for about 2 h [18]. In the cool night air the chemical vapor condensed and settled back to earth, hovering close to the ground as a moist fog. A soft wind from the north slowly pushed the toxic fog away from the factory and into the unsuspecting sleeping community in its path (Fig. 1.2) [19].

People sleeping in the communities surrounding the factory soon began waking up to the same irritation that the factory workers had felt inside the factory less than an hour earlier. Before long they were gasping for air. At this point many of them fled outside their homes hoping to find comfort, only to find that the situation was even worse in the streets.

Figure 1.2 Bhopal disaster dispersion analysis [20]. Google Maps

Those in the direct path of the vapor cloud were blinded and unable to breathe. Overcome with confusion, the crowds in the streets started to panic. Adults and children alike started running in every direction. In the darkness, nobody could see what was happening. A safe haven could be found nowhere. Many died in the stampede that followed as chaos spilled into the streets surrounding the factory [21].

The intermediate storage tank emptied and the release stopped at about 2:15 am [22]. More than 100,000 partially blinded survivors arrived at local hospitals during the first night [23]. Many of them were severely injured and suffering from acute breathing disorders. However, the hospitals were in no way prepared to handle the unexpected ...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Dedication

- About the Author

- Foreword

- Acknowledgments

- Introduction

- A Note for Readers

- Part 1. Process Reliability

- Part 2. Research and Development

- Part 3. Process Configuration

- Part 4. Operations and Production

- Part 5. Lessons Learned

- Appendix

- Glossary

- Index