- 630 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Applied Process Design for Chemical and Petrochemical Plants: Volume 1

About this book

This expanded edition introduces new design methods and is packed with examples, design charts, tables, and performance diagrams to add to the practical understanding of how selected equipment can be expected to perform in the process situation. A major addition is the comprehensive chapter on process safety design considerations, ranging from new devices and components to updated venting requirements for low-pressure storage tanks to the latest NFPA methods for sizing rupture disks and bursting panels, and more.*Completely revised and updated throughout*The definative guide for process engineers and designers*Covers a complete range of basic day-to-day operation topics

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Applied Process Design for Chemical and Petrochemical Plants: Volume 1 by Ernest E. Ludwig in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Chemistry. We have over one million books available in our catalogue for you to explore.

Information

Chapter 1

Process Planning, Scheduling and Flowsheet Design

Process engineering design is the application of chemical, mechanical, petroleum, gas and other engineering talents to the process-related development, planning, designs and decisions required for economical and effective completion of a process project [7]. Although process design engineers are organizationally located in research, technical service, economic evaluation, as well as other specific departments, the usual arrangement is to have them available to the engineering groups concerned with developing the engineering details of a project. This is in order to provide process details as well as to evaluate bids for the various items of equipment. Process design is usually a much more specific group responsibility in engineering contractor organizations than in a chemical or petrochemical production company, and the degree of distinction varies with the size of the organization.

The average process engineer has the following responsibilities:

1. Prepares studies of process cycles and systems for various product production or improvements or changes in existing production units; prepares material and heat balances.

2. Prepares economic studies associated with process performance.

3. Designs and/or specifies items of equipment required to define the process flowsheet or flow system; specifies corrosion resistant materials of construction.

4. Evaluates competitive bids for equipment.

5. Evaluates operating data for existing or test equipment.

6. Guides flowsheet draftsmen in detailed flowsheet preparation.

The process engineer also develops tests and interprets data and information from the research pilot plant. He aids in scaling-up the research type flow cycle to one of commercial feasibility.

The process engineer must understand the interrelationship between the various research, engineering, purchasing, expediting, construction and operational functions of a project. He must appreciate that each function may and often does affect or influence the process design decisions. For example, it is foolish to waste time designing or calculating in detail, when the basic components of the design cannot be economically fabricated, or if capable of being fabricated, cannot possibly be delivered by the construction schedule for the project. Some specific phases of a project that require process understanding include plant layout, materials of construction for corrosion as well as strength, start-up operations, trouble-shooting, maintenance, performance testing and the like.

Organizational Structure

The process design function may be placed in any one of several workable locations in an organization. These locations will be influenced by the primary function of the overall company, i.e., chemical production, engineering, engineering sales, design and manufacture of packaged or specific equipment manufacture, etc. For best efficiency, regardless of the business nature of the company, the process design being a specialty type operation, works best when specifically identified and given the necessary freedom of contact within and without the company to maintain a high level of practical, yet thorough direction.

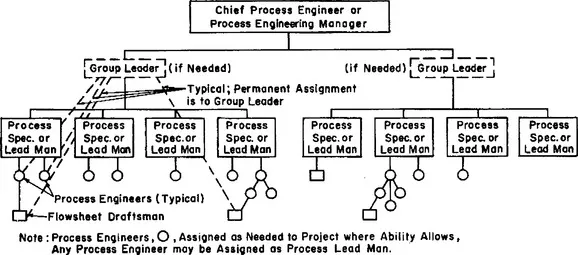

A typical working arrangement is shown in Figure 1-1 [7].

Figure 1-1 A process engineering section supervision chart. By permission, E. E. Ludwig [7].

In a consulting or engineering contractor organization, process design and/or process engineering is usually a separate group responsible for developing the process with the customer, or presenting the customer with a turnkey proposed process.

In an operating or producing chemical or petrochemical company the process engineering and design may be situated in a research, technical service, or engineering department. In most cases it is associated with an engineering department if new projects and processes are being planned for the company. If located elsewhere, the designs and planning must be closely coordinated with the engineering activity.

Most current thinking establishes a project team headed by a project engineer or manager to oversee the accomplishment of a given plant development for a process company. If the projects or jobs are small, then the scope of activity is limited and may often be consolidated in a single individual for project and process responsibility. For projects larger than $500,000, the project and process responsibility usually are best kept separate in order to expedite the specific accomplishm...

Table of contents

- Cover image

- Title page

- Table of Contents

- Inside Front Cover

- Dedication

- Inside Front Cover Two

- Copyright page

- Preface to the Third Edition

- Chapter 1: Process Planning, Scheduling and Flowsheet Design

- Chapter 2: Fluid Flow

- Chapter 3: Pumping of Liquids

- Chapter 4: Mechanical Separations

- Chapter 5: Mixing of Liquids

- Chapter 6: Ejectors and Mechanical Vacuum Systems

- Chapter 7: Process Safety and Pressure-Relieving Devices

- Appendix

- Index