- 792 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Periodic Operation of Chemical Reactors

About this book

This comprehensive review, prepared by 24 experts, many of whom are pioneers of the subject, brings together in one place over 40 years of research in this unique publication. This book will assist R & D specialists, research chemists, chemical engineers or process managers harnessing periodic operations to improve their process plant performance.

Periodic Operation of Reactors covers process fundamentals, research equipment and methods and provides "the state of the art" for the periodic operation of many industrially important catalytic reactions. Emphasis is on experimental results, modeling and simulation. Combined reaction and separation are dealt with, including simulated moving bed chromatographic, pressure and temperature swing and circulating bed reactors. Thus, Periodic Operation of Reactors offers readers a single comprehensive source for the broad and diverse new subject. This exciting new publication is a "must have" for any professional working in chemical process research and development.

- A comprehensive reference on the fundamentals, development and applications of periodic operation

- Contributors and editors include the pioneers of the subject as well as the leading researchers in the field

- Covers both fundamentals and the state of the art for each operation scenario, and brings all types of periodic operation together in a single volume

- Discussion is focused on experimental results rather than theoretical ones; provides a rich source of experimental data, plus process models

- Accompanying website with modelling data

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Topic

Scienze fisicheSubtopic

ChimicaChapter 1

Introduction

Robert Ross Hudgins∗, Peter Lewis Silveston∗, Albert Renken† and Yurii Sh. Matros∗∗, ∗Waterloo, Ontario, Canada, †Lausanne, Switzerland, ∗∗Springfield, Missouri, U.S.A

Outline

1.1 Periodic Operation

1.2 Origins of Periodic Operation

1.3 Variables in Periodic Operation

1.4 Cycle Structure in Periodic Operation

1.5 Measuring Improvement

1.6 Inherently Periodic Processes

1.7 Objectives of Periodic Operation

1.8 Strategies in Periodic Operation

1.9 Equipment for Periodic Operation

1.9.1 Laboratory Reactors

1.9.2 Industrial-Scale Equipment

1.10 Reaction Systems Examined

1.11 New Directions

1.11.1 Applications to Systems with Multiple Objectives

1.11.2 Control of Carbon Deposition

1.11.3 Modulation of Multiple Reactor Inputs

1.11.4 Improvement of Photocatalysis

1.12 A Brief History of the Study of Periodic Operation

1.12.1 Pioneers

1.12.2 Research Groups

1.12.3 Industrial Applications

The objective of this monograph is to summarize the large and growing literature on the periodic operation of chemical reactors. Research on such reactors is worldwide and the subject continues to attract new investigators, even though penetration of the technology into industry has been limited primarily to flow direction switching, simulated moving bed chromatographic reactors and swing reactors.

1.1 Periodic Operation

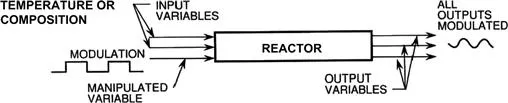

Periodic operation is a technique for enhancing the performance of a catalytic reactor, be it higher reactant conversion, better selectivity to a desired product, longer catalyst life or lower energy consumption. It involves periodically manipulating reactor inputs or the reactor environment. For example, composition or temperature of the feed to the reactor might be switched between two levels, as illustrated in Figure 1-1. This type of operation seems best suited to heterogeneous systems in which the catalyst is placed in a bed with reactants percolating through it, but examples for homogeneous, noncatalytic reactors are known (Renken, 1972). Simple cycles have been used in most research studies so far with just two composition or temperature levels employed. Some applications have combined separation and reaction so that more complicated cycles are involved.

FIGURE 1-1 Schematic of periodic reactor operation. (Figure reproduced from Silveston (1998) with permission.)

Figure 1-1 introduces the term “modulation,” the main term that will be used to describe simple periodic operation. However, the term cycling and occasionally forcing or periodic forcing will also be used. In all cases, this means one or more reactant concentration and/or temperature entering the reactor vary with time but in such a way that each “state” of an input is revisited after a time τ or τcycle corresponding to the period. A result of the manipulation shown in the figure is that most reactor outputs are modulated as well. Usually, it is not the instantaneous values of the outputs but rather their mean or time-averaged values that are of interest. It has been widely observed that over a range of modulation frequencies these means differ from outputs obtained under steady-state operation even when the reactor functions at the respective means of the inputs.

“Modulation” is not used for flow direction switching, a technique for energy saving or reactant recovery that is necessarily periodic. Indeed, work on this technology at the Boreskov Laboratory for Catalysis (Russia) beginning in the late 1960s (Boreskov et al., 1977a; Boreskov and Matros, 1983a; Matros and Bunimovich, 1995) initiated the present interest in periodic operations. Periodic flow direction switching is also referred to as periodic flow reversal.

Also considered in this monograph are other processes that are inherently periodic, such as adsorption or catalyst regeneration. In adsorption, a solid becomes fully or partially saturated after an interval of contact with a fluid phase and the adsorbate must be recovered or removed before a subsequent cycle commences. In catalytic processes, fouling residues or poisons must be stripped from the catalyst to maintain operation. Combined reaction-separation processes, considered in Chapters 20 to 22, are necessarily periodic. However, strictly adsorption processes, many of which are also periodic, will not be discussed. There is a large literature on those processes and current science and technology has been ably summarized (Ruthven, 1984; Suzuki, 1990; Crittendon and Thomas, 1998).

Although catalyst regeneration is indeed a periodic process, limits must be placed as catalyst regeneration is an enormous topic. Somewhat arbitrarily then, examination of periodic systems will be restricted to those whose maximum cycle time or period is of the order of an hour. Catalytic cracking will be bypassed, even though it falls within the time definition of a periodic operation, because this subject has been so thoroughly treated in the literature (see, e.g., Magee and Mitchell, 1993; Occelli and O’Connor, 1998; Sadeghbeigi, 2000; Occelli, 2004, 2007). The other extreme of milli or microsecond cycling will also be left out. This is the realm of acoustical stimulation or sono-catalysis. A large literature also exists in this field (e.g. Mason, 1997; Mason and Peters, 2002; Mason and Lorimer, 2002; Nowak, 2010).

The intent in this chapter is to present the concept of periodic operation. This includes objectives, potential variables, measurements of the operation, equipment used, cycle structure and strategies. For background, the historical development of this reactor application will be outlined. A few examples of applications will be given.

1.2 Origins of Periodic Operation

Periodic operation is not a new technique in Reactor Engineering. Repeated operation of a batch reactor over a duration of time is essentially a periodic operation. Batchwise operation, of course, goes back to the beginning of the discipline; indeed, to the origins of Chemical Engineering.

Any reactor in which the catalyst is regenerated in situ operates periodically. Even those reactors whose catalyst charge is removed for regeneration or replaced periodically share many similarities with periodic operation. Normally, time periods encountered for systems involving catalyst regeneration are measured in days, in months or even in years. In such cases, the reactor operates at steady state or quasi-steady state on the scale set by the residence time of reactants in the system. By quasi-steady state is meant a system that changes so slowly that the change is negligible on the time scale being used. Not all catalytic systems employing regeneration operate with long time periods. Catalytic cracking of gas oils, perhaps the largest regenerative systems in terms of production volume, is carried out using periods of the order of minutes. Of course, carrying out cracking in a fluidized bed becomes a steady-state operation for reactants and products. Only the catalyst particles experience a periodic environment as they move between reactor and regenerator.

In what follows, reaction systems are considered that are transient on the scale of residence times. The purpose of periodic operation discussed in this monograph differs from periodic catalyst regeneration in that it is intended to achieve performance that is either extremely expensive or impossible to attain under steady-state operation, whereas the intent of regeneration is simply to restore performance. With reference to separating reactors discussed in the last chapters, periodic operation enables the separation function.

Periodic operation is also encountered in other fields of Process Engineering. Heat recuperators have been used in steel making as well as other processes for well over a century. In steel making, these systems employ stacks of bricks to recover heat from stack gases, heat that is used to raise the temperature of air entering a furnace.

In the last two decades, periodically operated separating reactors (also called combined reaction-separation systems) have appeared in industry. Such reactors fall into two broad groups: 1) Chromatographic reactors in which a fluid stream desorbs products and unconverted reactant from solid surfaces and 2) swing reactors, in which pressure or temperature change is employed for desorption. More recently, systems operating with both pressure and temperature changes have been explored.

1.3 Variables in Periodic Operation

Composition modulation has been and remains a widely studied type of periodic operation. Figure 1-2 illustrates the operation. The figure also introduces the manipulated variables that define composition modulation: Period (τ or τcycle)—the time between repetitions of a change in an input condition, split (s)—the duration of a partial cycle relative to the period, amplitude (A)—the change in the value of an input condition from its mean, and the mean composition. The split, sometimes referred to as the duty fraction, measures the symmetry of a cycle. A value of s = 0.5 indicates a symmetrical cycle with each part of equal duration. For symmetrical cycling, these pa...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Preface

- About the Authors

- Chapter 1. Introduction

- Chapter 2. Hydrogenation Processes

- Chapter 3. Catalytic Oxidation and Reduction of Gases

- Chapter 4. Partial Oxidation and Dehydrogenation of Hydrocarbons

- Chapter 5. Combustion Systems

- Chapter 6. Automotive Exhaust Catalysis

- Chapter 7. Polymerization Under Modulation

- Chapter 8. Catalytic Gas-Solid Reactions

- Chapter 9. Electrochemical Processes

- Chapter 10. Modulation of Biological Processes

- Chapter 11. Miscellaneous Reactions

- Chapter 12. Modulation of Multiple Reactions

- Chapter 13. Use of Modulation in Mechanistic Studies

- Chapter 14. Evaluation of Periodic Processes

- Chapter 15. Pressure Modulation

- Chapter 16. Temperature Modulation

- Chapter 17. Flow Interruption in Trickle Beds

- Chapter 18. Periodic Flow Reversal

- Chapter 19. Control of Periodically Operated Reactors

- Chapter 20. Chromatographic Reactors

- Chapter 21. Simulated Moving Bed Chromatographic Reactors

- Chapter 22. Pressure and Temperature Swing Reactors

- Chapter 23. New Directions—Research and Development Challenges

- References

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Periodic Operation of Chemical Reactors by P. L. Silveston,R. R. Hudgins in PDF and/or ePUB format, as well as other popular books in Scienze fisiche & Chimica. We have over one million books available in our catalogue for you to explore.