- 168 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

HAZOP: Guide to Best Practice

About this book

HAZOP: Guide to Best Practice, 3rd Edition describes and illustrates the HAZOP study method, highlighting a variety of proven uses and approaches. This updated edition brings additional experience with which to assist the reader in delivering optimum safety and efficiency of performance of the HAZOP team. HAZOP is the most widely-used technique in the process industries for the identification of hazards and the planning of safety measures.

This book explains how to implement HAZOP techniques in new facilities and apply it to existing facilities. The content covers many of the possible applications of HAZOP and takes you through all the stages of a study. This simple, easily digestible book is a favorite in the chemical and process industries.

- A concise and clear guide to the do's and don'ts in HAZOP

- New edition brings additional experience to help you deliver optimum safety and efficiency of performance.

- Updated material includes a section on HAZOP study of a procedure with a detailed example, new sections on pre-meeting with the client auditing a study, human factors and linking HAZOP study to LOPA. A section on start-up and shutdown has been added to the chapter on specific applications of HAZOP.

Trusted by 375,005 students

Access to over 1 million titles for a fair monthly price.

Study more efficiently using our study tools.

Information

Chapter 1

Introduction

This chapter covers the specific aims of the Guide, namely, a detailed description of the methodology and application of HAZOP study. It includes a brief account of the origin of the method and the areas where it has been successfully applied. The essential features of HAZOP study are stated including its multidisciplinary team approach, line-by-line analysis of a firm design, and the combination of guidewords with parameters to seek deviations from the design intention. The need for assessment of risk is explained.

Keywords

HAZOP study; HAZOP methodology; essentials of HAZOP; hazard identification; operability; risk ranking

1.1 Aims and Objectives

This book is intended to provide guidance on a specific technique developed for use in the process and chemical industries. The technique described is HAZOP (hazard and operability) study, a detailed method for systematic examination of a well-defined process or operation, either planned or existing.

The HAZOP study method was developed by ICI in the 1960s and its use and development was encouraged by the Chemical Industries Association (CIA) Guide published in 1977. Since then, it has become the technique of choice for many of those involved in the design of new processes and operations. In addition to its power in identifying safety, health, and environmental (SHE) hazards, a HAZOP study can also be used to search for potential operating problems. Not surprisingly, the method has been applied in many different ways within the process industries.1

While it is frequently used on new facilities, it is now often applied to existing facilities and modifications. It has also been successfully applied to process documentation, pilot plant, and hazardous laboratory operations as well as tasks such as commissioning and decommissioning, emergency operations, and incident investigation.

The objective here is to describe and illustrate the HAZOP study method, showing a variety of uses and some of the approaches that have been successful within the process industry. An important input has come from European Process Safety Centre (EPSC) members where 22 member companies responded in a survey carried out prior to the first edition of this Guide (2000). This identified many features generally regarded as essential to a good study. In addition, many common variations were described. These variations are in part due to the range of problems encountered within industry but also reflect individual choices of style. HAZOP study is a versatile technique and good results may be achieved by several different approaches provided the basic principles are followed. It is hoped that this Guide will help maintain a high standard for HAZOP study within the industry, both by raising quality and encouraging flexibility without putting any unnecessary constraints upon its use and development.

The HAZOP study method is well developed and is useful in most applications. There are other methods, however, that may have to be considered depending on the complexity and hazards of the installation being constructed and the state of the design. This publication does not address these methods in detail but their importance is discussed in Chapter 2. A fuller account is given in the IChemE Guide, Hazard Identification Methods.2

Finally, three illustrations of process industry applications are given in Appendices 3, 4 and 5. These examples cannot fully represent all the possible applications and process industries and readers new to HAZOP study are advised to consult the reference list,3-6 the International Electrotechnical Commission (IEC) standard,7 or guidelines written specifically for other industries.

It is hoped that this guide will help people within the process industries, including all those with responsibilities within safety management systems. Although it is primarily written for HAZOP study leaders, scribes, and members, it may also be of use to those involved in training and plant management.

1.2 Essential Features of HAZOP Study

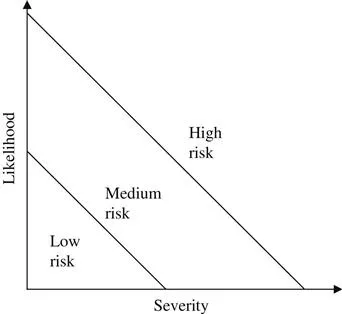

A HAZOP study is a structured analysis of a system, process, or operation for which detailed design information is available, carried out by a multidisciplinary team. The team proceeds on a line-by-line or stage-by-stage examination of a firm design for the process or operation. While being systematic and rigorous, the analysis also aims to be open and creative. This is done by using a set of guidewords in combination with the system parameters to seek meaningful deviations from the design intention. A meaningful deviation is one that is physically possible—for example, no flow, high pressure, or reverse reaction. Deviations such as no temperature or reverse viscosity have no sensible, physical meaning and are not considered. The team concentrates on those deviations that could lead to potential hazards to safety, health, or the environment. It is important to distinguish between the terms hazard and risk. They have been defined8 as follows: a “hazard” is a physical situation with the potential for human injury, damage to property, damage to the environment, or a combination of these. A “risk” is the likelihood of a specified undesirable event occurring within a specified period or in specified circumstances. It can also be expressed as a combination of likelihood and severity, as illustrated in Figure 1.1.

In addition to the identification of hazards, it is common practice for the team to search for potential operating problems. These may concern security, human factors, quality, financial loss, or design defects.

Where causes of a deviation are found, the team evaluates the consequences using experience and judgment. If the existing safeguards are adjudged to be inadequate, then the team recommends an action for change or calls for further investigation of the problem. The consequences and related actions may be risk-ranked. The analysis is recorded and presented as a written report which is used in the implementation of the actions.

To avoid misunderstanding and confusion with other forms of process hazard study or project hazard review, the term HAZOP study is reserved for studies which include the essential features outlined earlier in this section. Descriptions such as “coarse scale HAZOP” or “checklist HAZOP” should be avoided.

Chapter 2

Process Hazard Studies

Safety legislation in the EU and the USA. A brief review of the range of Hazard Study (HS) that may be considered in both major and minor projects, outlining the principal features of HS 0–7. Illustration of the relevance of each study to the main phases of a project. The place of HAZOP study within the series is shown. The choice of HS methods for projects of different hazard potential is listed including alternatives to HAZOP study. Finally, an illustrative checklist is provided for the very important HS2 (project definition stage).

Keywords

Safety legislation; hazard studies 0–7; project life cycle; HS selection; HAZOP alternatives; HS2 checklist

Within the process industries, significant attention has been given to the development of comprehensive safety management systems (SMSs) or SHE management systems with the objective of protecting workers, the public, and the environment. There are also requirements within legislation such as the Seveso II Directive, European Union (EU) Directive 96/82/EC,9 and subsequent country-specific legislation, requiring those companies handling hazardous materials to have in place an adequate SMS and to fulfill specified obligations. These requirements range from the preparation of Major Accident Prevention Policies to submission of detailed safety reports to a competent authority. Other non-EU countries have similar legislation—for example, the Office of Safety and Health Administration (USA) (OSHA) regulation 29CFR, Part 1910.119 (1992), Process Safety Management (PSM)10 in the USA. An integral element of such systems is the use of systematic techniques for the identification of hazards. In addition to meeting legal requirements, there are considerable business benefits to be gained from the use of a systematic and thorough approach to hazard identification. These benefits include improvement of quality, faster start-up, and a reduction of subsequent operability problems.

For a new project, the greatest benefit is obtained by carrying out a number of studies throughout the design process. One such sequence is the Hazard Study (HS) methodology developed by ICI which used six stages.4,11 Each study verifies that the actions of previous studies have been carried out and signed off, and that the hazard and environmental issues have been identified and are being addressed in a timely and detailed manner.

2.1 HS 1—Concept Stage Hazard Review

In this first study, the basic hazards of the materials and the operation are identified and SHE criteria set. It identifies what information is needed and the program of studies required to ensure that all SHE issues are adequately addressed. The aspects covered may include reaction kinetics, toxicity data, environmental impact, and any special process features that need further evaluation. In addition, any constraints due to relevant legislation are identified. A decision may be taken on which of the remaining hazard studies (two to six) should also be undertaken. It is also important at this early stage to apply the principles of inherent SHE12,13 within the design. This aims to eliminate, avoid, or reduce pot...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Foreword

- Acknowledgments

- Chapter 1. Introduction

- Chapter 2. Process Hazard Studies

- Chapter 3. The HAZOP Study Method

- Chapter 4. The Detailed HAZOP Study Procedure

- Chapter 5. Organizing a HAZOP Study

- Chapter 6. Carrying Out a Study

- Chapter 7. Recording and Auditing

- Chapter 8. Training

- Chapter 9. Company Procedures for HAZOP Study

- Chapter 10. Advanced Aspects of HAZOP Study

- Chapter 11. Specific Applications of HAZOP

- Chapter 12. Factors for a Successful HAZOP Study

- Appendix 1. The Guideword-First Approach to HAZOP

- Appendix 2. The Use of Checklists Within HAZOP Study

- Appendix 3. An Illustration of HAZOP Study for a Continuous Operation

- Appendix 4. An Illustration of HAZOP Study for a Batch Operation

- Appendix 5. An Illustration of HAZOP Study for a Procedure

- Acronyms and Abbreviations

- References and Bibliography

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access HAZOP: Guide to Best Practice by Frank Crawley,Brian Tyler in PDF and/or ePUB format, as well as other popular books in Business & Insurance. We have over one million books available in our catalogue for you to explore.