- 492 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Advances in Composites Manufacturing and Process Design

About this book

The manufacturing processes of composite materials are numerous and often complex. Continuous research into the subject area has made it hugely relevant with new advances enriching our understanding and helping us overcome design and manufacturing challenges. Advances in Composites Manufacturing and Process Design provides comprehensive coverage of all processing techniques in the field with a strong emphasis on recent advances, modeling and simulation of the design process.Part One reviews the advances in composite manufacturing processes and includes detailed coverage of braiding, knitting, weaving, fibre placement, draping, machining and drilling, and 3D composite processes. There are also highly informative chapters on thermoplastic and ceramic composite manufacturing processes, and repairing composites. The mechanical behaviour of reinforcements and the numerical simulation of composite manufacturing processes are examined in Part Two. Chapters examine the properties and behaviour of textile reinforcements and resins. The final chapters of the book investigate finite element analysis of composite forming, numerical simulation of flow processes, pultrusion processes and modeling of chemical vapour infiltration processes.- Outlines the advances in the different methods of composite manufacturing processes- Provides extensive information on the thermo-mechanical behavior of reinforcements and composite prepregs- Reviews numerical simulations of forming and flow processes, as well as pultrusion processes and modeling chemical vapor infiltration

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

Braiding processes for composites manufacture

2 University of Stuttgart, Stuttgart, Germany

Abstract

1.1 Introduction

1.2 Braiding process

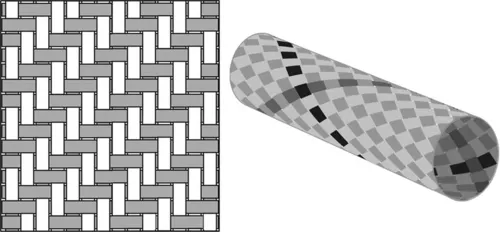

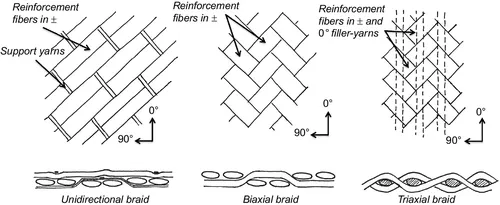

1.2.1 Principle

1.2.2 Variants of braids

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- List of contributors

- Preface

- Woodhead Publishing Series in Composites Science and Engineering

- Part One: Advances in composite manufacturing processes

- Part Two: Mechanical behaviour of reinforcements and numerical simulation of processes in composites manufacturing

- Index