Feedstock Technology for Reactive Metal Injection Molding

Process, Design, and Application

- 266 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Feedstock Technology for Reactive Metal Injection Molding

Process, Design, and Application

About this book

Feedstock Technology for Reactive Metal Injection Molding: Process, Design, and Application provides an authoritative guide on the basics of feedstock technology and the latest developments in binders for titanium metal injection moulding and their potential implications. In addition, the book presents challenges that MIM technology of reactive metals is currently facing and potential solutions for commercial success. As both commercial growth and research development are fundamentally driven by the economics of manufacture, this book presents the problems and potential solutions regarding reactive metals, making it a valuable resource for engineers intending to utilize MIM in commercial product design.- Provides comprehensive details and case studies on the feedstocks currently under extensive development, in research and in the commercial domain- Discusses the most recent developments of binder chemistry and design, along with the most critical challenges in MIM technology- Includes comprehensive evaluations with regard to feedstock characterization and impurity control

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

Reactive powder metal injection molding

Abstract

Keywords

1.1 Metal injection molding—a standout manufacturing technology?

1.2 Overview of metal injection molding

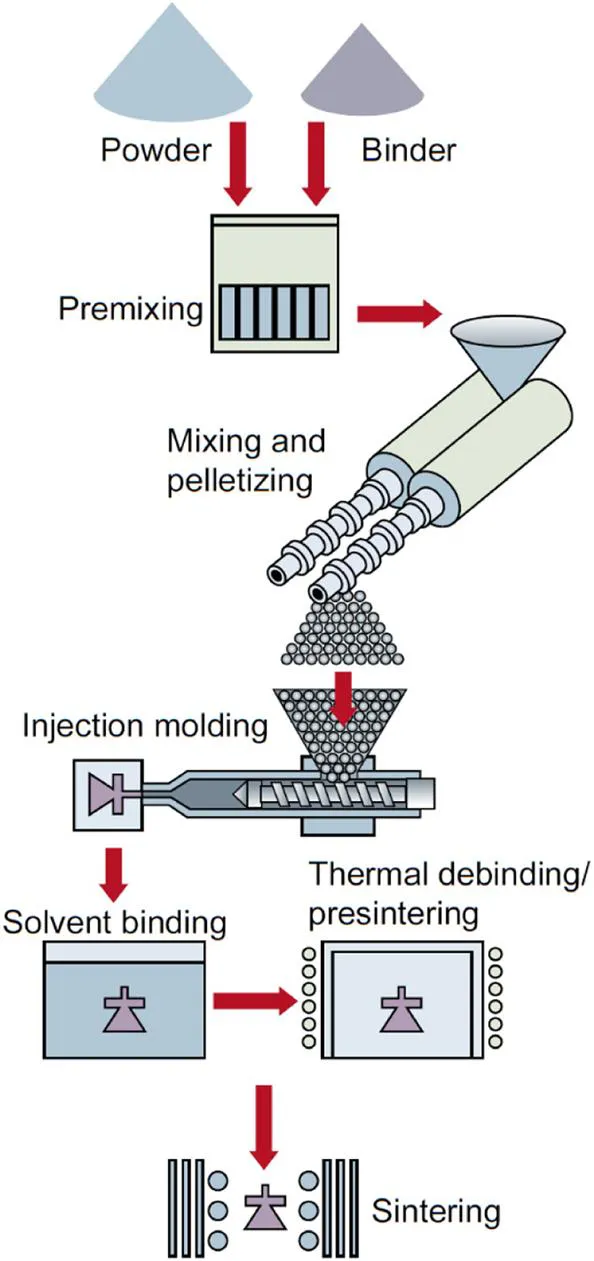

1.2.1 Metal injection molding processes

1.2.2 Design consideration

| Attributes | Minimum | Typical | Maximum |

|---|---|---|---|

| Component mass (g) | 0.030 | 10–15 | 300 |

| Max. dimension (mm) | 2 | 25 | 150 |

| Min. wall thickness (mm) | 0.025 | 5 | 15 |

| Tolerance (%) | 0.2 | 0.5 | 1 |

| Density (%) | 93 | 98 | 100 |

| Production quantity | 1000 | 100,000 | 100,000,000 |

| Surface finish (µm) | 0.3 | 0.8 | 1 |

- 1. Avoid components over 12.5 mm thick. In cases where thick sections are desired, special modifications to the binder system ...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Chapter 1. Reactive powder metal injection molding

- Chapter 2. Design strategy of binder systems and feedstock chemistry

- Chapter 3. Binder system interactions and their effects

- Chapter 4. Impurity management in reactive metals injection molding

- Chapter 5. Potential feedstock compositions for metal injection molding of reactive metals

- Chapter 6. Outlook of reactive metal injection molding

- Index