Tribology of Abrasive Machining Processes

- 600 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Tribology of Abrasive Machining Processes

About this book

This book draws upon the science of tribology to understand, predict and improve abrasive machining processes. Pulling together information on how abrasives work, the authors, who are renowned experts in abrasive technology, demonstrate how tribology can be applied as a tool to improve abrasive machining processes.Each of the main elements of the abrasive machining system are looked at, and the tribological factors that control the efficiency and quality of the processes are described. Since grinding is by far the most commonly employed abrasive machining process, it is dealt with in particular detail.Solutions are posed to many of the most commonly experienced industrial problems, such as poor accuracy, poor surface quality, rapid wheel wear, vibrations, work-piece burn and high process costs. This practical approach makes this book an essential tool for practicing engineers.- Uses the science of tribology to improve understanding and of abrasive machining processes in order to increase performance, productivity and surface quality of final products- A comprehensive reference on how abrasives work, covering kinematics, heat transfer, thermal stresses, molecular dynamics, fluids and the tribology of lubricants- Authoritative and ground-breaking in its first edition, the 2nd edition includes 30% new and updated material, including new topics such as CMP (Chemical Mechanical Polishing) and precision machining for micro-and nano-scale applications

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

Part 1

Introduction

1

Introduction

Chapter Outline

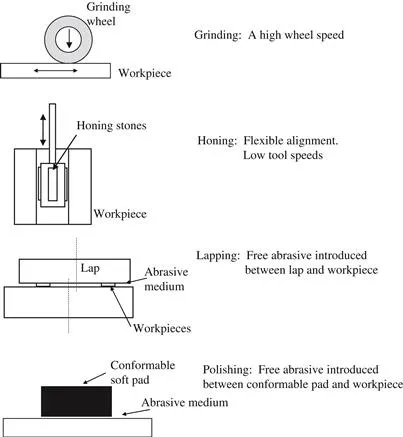

1.1 Abrasive processes

1.1.1 Grinding

1.1.2 Honing

1.1.3 Lapping

1.1.4 Polishing

1.2 Abrasives

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Preface to the first edition

- Preface to the second edition

- About the authors

- Part 1: Introduction

- Part 2: Physical Mechanisms

- Part 3: Application of Abrasive Tools

- Part 4: Process Fluids, Tribo-chemistryand Materials

- Symbols and units

- Glossary

- Index