- 450 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

Distillation: Operation and Applications—winner of the 2015 PROSE Award in Chemistry & Physics from the Association of American Publishers—is a single source of authoritative information on all aspects of the theory and practice of modern distillation, suitable for advanced students and professionals working in a laboratory, industrial plants, or a managerial capacity. It addresses the most important and current research on industrial distillation, including all steps in process design (feasibility study, modeling, and experimental validation), together with operation and control aspects. This volume features an extra focus on distillation applications.

- Winner of the 2015 PROSE Award in Chemistry & Physics from the Association of American Publishers

- Practical information on the newest development written by recognized experts

- Coverage of a huge range of laboratory and industrial distillation approaches

- Extensive references for each chapter facilitates further study

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Topic

Physical SciencesSubtopic

Analytic ChemistryChapter 1

Distillation Control

William L. Luyben Department of Chemical Engineering, Lehigh University, Bethlehem, PA, USA

Abstract

Effective control of the many distillation columns in a chemical, petroleum, or biochemical process is vital for the profitable operation of a plant. Initial separations of raw material feedstocks often are performed in distillation columns, and any variability in this initial operation will upset the entire plant. Final purifications of product streams often occur in distillation columns and therefore have a direct impact on product quality.

Distillation columns are typically major consumers of energy, so their efficient operation has a large impact on the bottom line economics. The column control system must be capable of minimizing energy consumption while simultaneously providing stable dynamic control of the unit.

Even a simple single-feed, two-product column presents a multivariable control problem with the unavoidable issues of loop interaction, controlled and manipulated variable pairing, and controller tuning. This chapter attempts to summarize briefly the problems with and approaches to developing effective control structures for a wide variety of distillation columns.

Keywords

Controller tuning; Control structure; Dual-end control; Distillation control; Energy efficiency; Single-end control1.1. Introduction

Distillation control has been the subject of dozens of books and thousands of papers over the past half century. No other unit operation has received as much attention by both academic and industrial workers. A complete listing of all these references is impractical and of limited utility. A list of books that deal explicitly with distillation control is given in the Reference section [1–6]. The earliest reference dates back almost four decades [1], and the latest was published in 2013 [6].

Distillation columns come in many flavors, and no one control structure fits all columns. Differences in feed compositions, relative volatilities, product purities, and energy costs impact the selection of the “best” control structure for a given column in a given plant.

1.2. Basic control issues

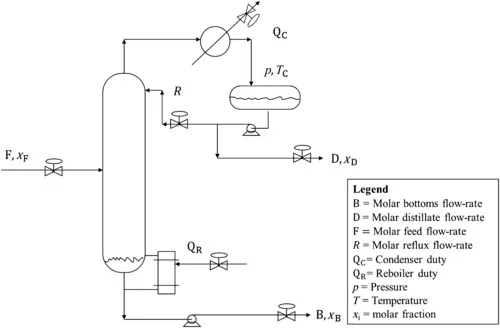

Let us consider a plain vanilla distillation column with a single feed stream that produces a distillate product from a total condenser/reflux drum and a bottom product from a partial reboiler in the column base. Figure 1.1 sketches the flowsheet and gives the nomenclature used in this chapter. All flow rates are molar and all compositions are molar fractions. If the feed stream is set by an upstream unit, there are five control valves in this process (distillate, reflux, cooling water, reboiler steam, and bottoms), each of which must somehow be set. Thus the system is inherently a 5 × 5 multivariable process. There are five-factorial possible combinations of variable pairings (120 possible control structures).

There are three variables that must be controlled: pressure, liquid level in the reflux drum, and liquid level in the base. A typical control structure would control pressure with condenser cooling water, reflux drum level with distillate, and base level with bottom stream. This leaves two control degrees of freedom available to control two variables.

In the design of a column, the normal design specifications are the purities (or impurities) of the two products. The amount of heavy key component in the distillate and the amount of light key component in the bottom stream are normally specified. In theory, these same specifications should be used to control the operating column. This “dual-composition control” structure is used in some columns, usually when separations are difficult (low relative volatilities) and energy is expensive. It requires, of course, two on-line composition measurements, which are sometimes expensive, require high maintenance, and introduce significant deadtimes in the loop. As a result, the vast majority of columns use a more simple control structure in which the two remaining control degrees of freedom hold the temperature on a suitable tray and control the ratio of reflux-to-feed, or reflux ratio (RR).

From a fundamental standpoint, the two parameters that affect product purities are material balance and fractionation. Material balance refers to how the feed stream to the column is split between the distillate and the bottom stream. This is sometimes called the cut point or product split. In an extreme case in which 100% of the feed stream is taken overhead as the distillate product, the composition of the distillate will obviously be equal to the feed composition. No amount of reflux will affect the distillate composition. The same is true if the entire feed stream goes out the bottom. It is clear that the product split has a major effect on the compositions of the products.

By fractionation we mean the energy put into...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Preface to the Distillation Collection

- Preface to Distillation: Operation and Applications

- List of Contributors

- List of Symbols and Abbreviations

- Chapter 1. Distillation Control

- Chapter 2. Common Techniques for Distillation Troubleshooting

- Chapter 3. Column Performance Testing Procedures

- Chapter 4. Distillation in Refining

- Chapter 5. Distillation of Bulk Chemicals

- Chapter 6. Air Distillation

- Chapter 7. Distillation of Specialty Chemicals

- Chapter 8. Distillation in Bioprocessing

- Chapter 9. Special Distillation Applications

- Chapter 10. New Separating Agents for Distillation

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Distillation by Andrzej Gorak,Hartmut Schoenmakers in PDF and/or ePUB format, as well as other popular books in Physical Sciences & Analytic Chemistry. We have over one million books available in our catalogue for you to explore.