eBook - ePub

Residual Stresses in Friction Stir Welding

- 60 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Residual Stresses in Friction Stir Welding

About this book

This book describes the fundamentals of residual stresses in friction stir welding and reviews the data reported for various materials. Residual stresses produced during manufacturing processes lead to distortion of structures. It is critical to understand and mitigate residual stresses. From the onset of friction stir welding, claims have been made about the lower magnitude of residual stresses. The lower residual stresses are partly due to lower peak temperature and shorter time at temperature during friction stir welding. A review of residual stresses that result from the friction stir process and strategies to mitigate it have been presented. Friction stir welding can be combined with additional in-situ and ex-situ manufacturing steps to lower the final residual stresses. Modeling of residual stresses highlights the relationship between clamping constraint and development of distortion. For many applications, management of residual stresses can be critical for qualification of component/structure.

- Reviews magnitude of residual stresses in various metals and alloys

- Discusses mitigation strategies for residual stresses during friction stir welding

- Covers fundamental origin of residual stresses and distortion

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Residual Stresses in Friction Stir Welding by Nilesh Kulkarni,Rajiv S. Mishra,John A. Baumann in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Materials Science. We have over one million books available in our catalogue for you to explore.

Information

Chapter 1

Introduction

Today welding is being widely used as a joining process in myriad of structural applications such as buildings, offshore petroleum rigs, pressure vessels, and ships. In fact, before World War II, all the ships contained riveted structures, whereas today they have been replaced mostly with welding. The reason for such a widespread use is several advantages that welding offers over competing joining techniques, especially riveting. The welded structures are generally lighter and have higher joint efficiency. It also simplifies the joint design which results in smaller fabrication time. Despite possessing several unique joining characteristics, it has several drawbacks. In fusion welding techniques, defects such as liquation cracking, solidification induced porosities, and inclusions from slag are quite common. Residual stresses (RS) are common to both fusion and solid-state welding techniques. RS are the result of sharp inhomogeneous thermal gradient which results in complex thermal stresses in the weld. It eventually leads to the introduction of RS and resulting distortion of the weldments.

The scope of this book is to get an insight into RS induced in components joined by friction stir welding (FSW) technique by summarizing published literature. It will help practitioners of this technology to develop understanding about the factors controlling RS generation and their mitigation.

1.1 Residual Stresses

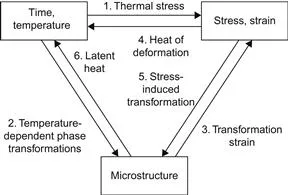

Residual stresses are defined as self-equilibrating stresses which exist in an elastic body even in absence of external loads (thermal and/or mechanical). In Figure 1.1, the origin of RS has been depicted, schematically, as a consequence of interactions among thermal history (time and temperature), deformation (stress and strain), and material microstructure [1]. Clearly, these stresses are results of thermal and/or mechanical treatment of components during their manufacturing (through casting, metalworking, welding, physical vapor deposition, etc.). Figure 1.2 illustrates some of the manufacturing scenarios which can introduce RS in various components [2]. The complete removal of RS may not be possible. However, by following proper manufacturing techniques, they can be mitigated to a large extent. Hence, the knowledge of factors influencing the state of RS is very important for managing RS.

Figure 1.1 Schematic representation of residual stress as a consequence of interactions among factors as shown in boxes [1].

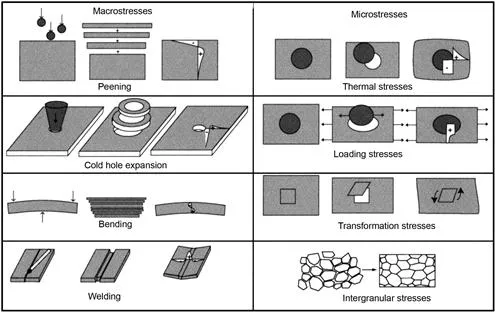

Figure 1.2 Schematic representation of RS as a misfit between different regions under different thermo-mechanical processing conditions [2].

RS occur at different length scales in materials. Depending upon length scale at which they are present, they can be classified into type I, II, or III. Type I is referred to as macrostress and varies over the scale of the structure. Type II varies and self-equilibrates over the scale of several grains. Type III varies over less than the scale of a grain. The stresses existing in welded component due to nonuniform heating and cooling and sharp thermal gradient can be categorized into type I. Stresses existing in composite materials due to different elastic and thermal properties can come under type II. The stresses associated with dislocations and vacancies come under type III. All these three types of RS have been summarized in Figure 1.3 [2]. In a given component depending on its processing history, all three types of stresses may coexist. Since the present book deals with RS in weldments, it will focus only on type I RS.

Figure 1.3 Schematic representation of type I, II, and III RS [2].

1.2 Implication of RS

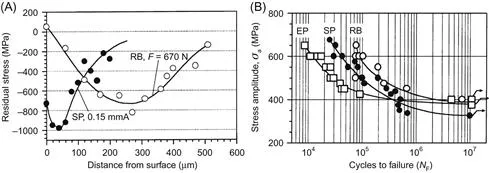

Depending upon the nature of RS, the presence of RS can have detrimental or beneficial effects on the service life or performance of a component. For example, surface treatment techniques such as shot peening which introduces compressive RS are known to improve fatigue life of the parts. Cold hole expansion (Figure 1.2) is another example which introduces compressive stresses around the hole thereby improving fatigue life [3]. Figure 1.4 has been included to illustrate the positive effect of such surface treatments (shot peening, roller-burnishing, etc.) on mechanical properties, such as fatigue [4]. In Figure 1.4A, it can be noted that these techniques introduce compressive stresses in the surface of the components. Compressive RS help improve the fatigue life by retarding the rate of surface/subsurface crack growth. The toughening of glasses to improve fracture strength by way of introducing compressive stresses on the surface is another example of beneficial effect of RS.

Figure 1.4 Effect of surface treatment techniques: (A) shot peening (SP) and roller-burnishing (RB) on the state of RS and (B) on fatigue life (EP: electrolytic polishing) [4].

Due to detrimental effect of RS (compressive or tensile), structural components may get severely distorted which can result in the rejection of the parts or the presence of RS can bring down the service life of a component quite significantly.

Hence, the knowledge of RS as a result of primary (e.g., casting) or secondary (e.g., machining) manufacturing processes is essential. As mentioned earlier, the scope of the book is limited to RS in FSW process, so in the following sections, various factors governing RS, the role of RS on mechanical properties, and how they can be reduced or eliminated is discussed.

Chapter 2

A Brief Introduction to FSW

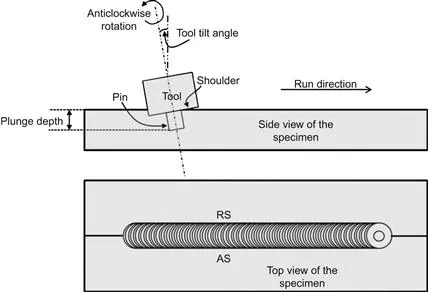

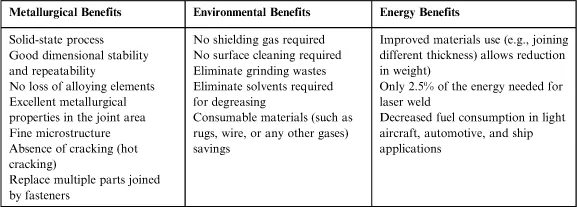

FSW was developed at The Welding Institute (TWI) in 1991 [5]. The working principle of FSW/P is remarkably simple [6]. In this process, in its simplest form, a nonconsumable rotating tool plunges inside a material at the joint line of two butting plates to be welded and traverses along the weld line, which results in weld formation and modification of microstructure. During welding, the temperature in the material never exceeds the solidus temperature of the material and the whole process is performed in the solid state. The schematic of the process has been shown in Figure 2.1 and relevant regions of FSW process have been labeled. Table 2.1 lists important beneficial effects of FSW technique [7].

Figure 2.1 A schematic of friction stir welding process.

Table 2.1

Major Advantages of FSW Technique

Source: Reproduced from Ref. [7].

Due to similarity of FSW to other thermo-mechanical processes to some extent, this technique of material joining/processing is expected to lead to introduction of RS in the fabricated components. Since entire welding takes place below melting point of the alloy(s) being joined, at early stages of FSW development, the RS were thought to be negligible compared to fusion welding technique. However, the research carried out in last one decade or so has revealed that the RS in friction stir weldments can be significant. Hence, subsequent sections deal with different aspects of RS in FSW process.

Chapter 3

RS in FSW Process

3.1 Materials Studied

The materials investigated for the purpose of studying RS i...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Preface to the Friction Stir Welding and Processing Book Series

- Chapter 1. Introduction

- Chapter 2. A Brief Introduction to FSW

- Chapter 3. RS in FSW Process

- Chapter 4. Effect of RS on Properties

- Chapter 5. Parameters Affecting RS

- Chapter 6. Characterization of RS

- Chapter 7. Model for Understanding Residual Stress Development in Friction Stir-Welded Structures

- Chapter 8. Mitigation of RS During FSW

- Chapter 9. Simulation of FSW for RS and Distortions

- Chapter 10. Summary, Conclusions, and Future Direction

- References