eBook - ePub

Practical Machinery Management for Process Plants: Volume 2

Machinery Failure Analysis and Troubleshooting

- 700 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Practical Machinery Management for Process Plants: Volume 2

Machinery Failure Analysis and Troubleshooting

About this book

This newly expanded edition discusses proven approaches to defining causes of machinery failure as well as methods for analyzing and troubleshooting failures.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Practical Machinery Management for Process Plants: Volume 2 by Heinz P. Bloch,Fred K. Geitner in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Mechanical Engineering. We have over one million books available in our catalogue for you to explore.

Information

Practical Machinery Management for Process Plants, Vol. 2, Suppl. (C), 1999

ISSN: 1874-6942

doi: 10.1016/S1874-6942(99)80003-0

Chapter 1 The Failure Analysis and Troubleshooting System

Troubleshooting as an Extension of Failure Analysis

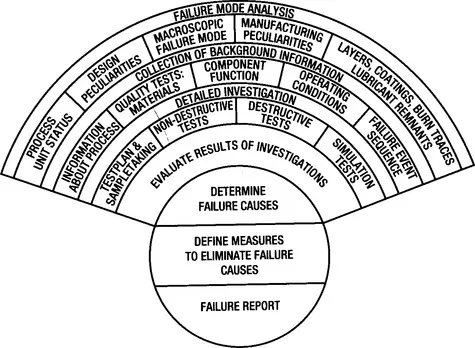

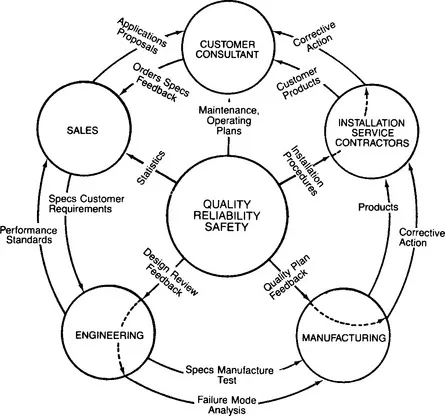

For years, the term “failure analysis” has had a specific meaning in connection with fracture mechanics and corrosion failure analysis activities carried out by static process equipment inspection groups. Figure 1-1 shows a basic outline of materials failure analysis steps.1 The methods applied in our context of process machinery failure analysis are basically the same; however, they are not limited to metallurgic investigations. Here, failure analysis is the determination of failure modes of machinery components and their most probable causes. Figure 1-2 illustrates the general significance of machinery component failure mode analysis as it relates to quality, reliability, and safety efforts in the product development of a major turbine manufacturer.2

Figure 1-1 Failure analysis steps—materials technology (modified from Ref. 1).

Figure 1-2 Failure analysis and the “wheel of quality.”2

Very often, machinery failures reveal a reaction chain of cause and effect. The end of the chain is usually a performance deficiency commonly referred to as the symptom, trouble, or simply “the problem.” Troubleshooting works backward to define the elements of the reaction chain and then proceeds to link the most probable failure cause based on failure (app...

Table of contents

- Cover image

- Title page

- Table of Contents

- Practical Machinery Management for Process Plants:

- Front matter

- Dedication

- Copyright page

- Acknowledgments

- Preface

- Chapter 1: The Failure Analysis and Troubleshooting System

- Chapter 2: Metallurgical Failure Analysis

- Chapter 3: Machinery Component Failure Analysis

- Chapter 4: Machinery Troubleshooting

- Chapter 5: Vibration Analysis

- Chapter 6: Generalized Machinery Problem-Solving Sequence

- Chapter 7: Statistical Approaches in Machinery Problem Solving

- Chapter 8: Sneak Analysis

- Chapter 9: Formalized Failure Reporting as a Teaching Tool

- Chapter 10: The “Seven Cause Category Approach” to Root-Cause Failure Analysis

- Chapter 11: Cause Analysis by Pursuing The Cause-and-Effect Relationship*

- Chapter 12: Knowledge-Based Systems for Machinery Failure Diagnosis

- Chapter 13: Training and Organizing for Successful Failure Analysis and Troubleshooting

- Appendix A. Machinery Equipment Life Data1,2

- Appendix B. Theory of Hazard Plotting*

- Appendix C. Glossary of Problem-Solving and Decision-Making Terms

- Appendix D. Gear Nomenclature

- Index