- 282 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Digital Twin Driven Smart Manufacturing

About this book

Digital Twin Driven Smart Manufacturing examines the background, latest research, and application models for digital twin technology, and shows how it can be central to a smart manufacturing process.The interest in digital twin in manufacturing is driven by a need for excellent product reliability, and an overall trend towards intelligent, and connected manufacturing systems. This book provides an ideal entry point to this subject for readers in industry and academia, as it answers the questions: (a) What is a digital twin? (b) How to construct a digital twin? (c) How to use a digital twin to improve manufacturing efficiency? (d) What are the essential activities in the implementation of a digital twin? (e) What are the most important obstacles to overcome for the successful deployment of a digital twin? (f) What are the relations between digital twin and New Technologies? (g) How to combine digital twin with the New Technologies to achieve high efficiency and smartness in manufacturing?This book focuses on these problems as it aims to help readers make the best use of digital twin technology towards smart manufacturing.

- Analyzes the differences, synergies and possibilities for integration between digital twin technology and other technologies, such as big data, service and Internet of Things

- Discuss new requirements for a traditional three-dimension digital twin and proposes a methodology for a five-dimension version

- Investigates new models for optimized manufacturing, prognostics and health management, and cyber-physical fusion based on the digital twin

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Part 1

Background and Connotation

Outline

Chapter 1

Background and Concept of Digital Twin

Abstract

With the developments of new generation information technologies (New IT), such as cloud computing, Internet of Things (IoT), big data and artificial intelligence (AI), a smart manufacturing era is emerging. Accordingly, various national manufacturing development strategies have been put forward, such as Industry 4.0, the Industrial Internet, manufacturing based on cyber–physical system(CPS), and Made in China 2025. It is clear that achieving cyber–physical fusion is a crucial step for the implementation of smart manufacturing. Although CPS provides the framework and mechanism for seamless interaction between physical and cyber components, it mainly belongs to the academic category and focuses on the verification of scientific principles rather than the practical optimization of engineering applications. Therefore, digital twin (DT) is introduced as a pragmatic way for cyber–physical fusion. In this chapter, the background and history of DT are introduced. The different understandings of the DT concept from researchers in academia and practitioners in industry are next reviewed. Some concepts related to DT are also introduced to provide a deeper insight. Finally, the potential benefits of DT are concluded.

Keywords

Digital twin (DT); concept; digital thread; digital shadow; product lifecycle management (PLM)

With the developments of new generation information technologies (New IT), such as cloud computing, Internet of Things (IoT), big data and artificial intelligence (AI), a smart manufacturing era is emerging. Accordingly, various national manufacturing development strategies have been put forward, such as Industry 4.0, the Industrial Internet, manufacturing based on cyber–physical system(CPS), and Made in China 2025. It is clear that achieving cyber–physical fusion is a crucial step for the implementation of smart manufacturing. Although CPS provides the framework and mechanism for seamless interaction between physical and cyber components, it mainly belongs to the academic category and focuses on the verification of scientific principles rather than the practical optimization of engineering applications. Therefore, digital twin (DT) is introduced as a pragmatic way for cyber–physical fusion. In this chapter, the background and history of DT are introduced. The different understandings of the DT concept from researchers in academia and practitioners in industry are next reviewed. Some concepts related to DT are also introduced to provide a deeper insight. Finally, the potential benefits of DT are concluded.

1.1 Background of the Development of Digital Twin

In the past, physical space played the main role in industry. In those days, physical assets close in distance were organized by humans to handle design and manufacturing tasks. However, due to limited personal capabilities and geographical constraints, high efficiency was hard to achieve. Until the 20th century, technologies such as computers, simulation tools, the Internet, and wireless networks have helped to create a parallel virtual space that could virtualize physical assets, organize them with the aid of computing facilities, and enable the cooperation with assets remotely. This has provided a possibility to conduct plans and operations more efficiently and effectively. Nowadays, along with the developments of new generation information technologies (New IT), such as cloud computing, the Internet of Things (IoT), big data, and artificial intelligence (AI), the roles of the virtual space are becoming increasingly important and interactions between the physical and virtual spaces are more active than ever before. Therefore, seamless integration and fusion between the two spaces will be an inevitable trend, which will create a new potential to improve the current situations and technologies in the fields of design, manufacturing, service, etc.

Various countries are converging on this trend as the next industrial revolution and have proposed related national strategies, such as Industry 4.0, the Industrial Internet, and Made in China 2025. Although the strategies are proposed under different environments, their common objective is to capture the great opportunity brought by the seamless integration and fusion of the physical and virtual spaces for improving the national industry. As cyber–physical system (CPS) is an architecture to converge the physical and virtual spaces, they have attracted a large amount of attention from industrialists, researchers, and practitioners in recent years. CPS aims at embedding communication and computing capacities into physical assets to allow the physical space to be monitored, coordinated, and controlled by the virtual side in real-time to realize a seamless coupling. Many systems related to CPS have emerged rapidly in different fields, such as the cyber–physical production system (CPPS) [1], cloud-based CPS [2], cyber–physical–social system [3], and CPS-based smart agent system [4]. Just as the Internet has transformed how humans interact with each other through interconnecting computer networks, CPS will transform how humans interact with entities through integrating the physical and virtual spaces [5].

Although CPS provides the framework and mechanism for the integration between physical and virtual spaces, it is mainly conceptual aiming at inspiring new scientific foundations and technologies, rather than practical solutions to directly guide the development of engineered systems. As digital twin (DT) is a focused application of the CPS and provides more practical values and implementation details, it is introduced as a pragmatic way for seamless integration and fusion. With respect to the DT, for each physical object, there exists a virtual mirror model with abilities of analyzing, evaluating, optimizing and predicting, etc. The two parts interact with each other and remain synchronous in forming a closed loop. In addition, data from both the physical and virtual sides can be obtained and fused to generate more comprehensive information. In fact, the DT can be considered as a paradigm of CPS, as it consists of the most important components of CPS (i.e., the physical object, the virtual counterpart, and the connection of the two parts) and becomes more concrete. To date, an increasing number of organizations and companies are aware of the values of the DT, investing a large amount of resources into relevant research and deployment. In future, greater capabilities of the DT will be explored and it will play a growing role in industry for the integration and fusion between the physical and virtual spaces.

1.2 History of Digital Twin

The concept of “twin” was generated from NASA’s Apollo program, which built two real identical space vehicles. One of them was launched into the air space to perform the mission, while the other stayed on Earth, allowing engineers to mirror the conditions of the launched one [6]. According to the Whitepaper written by Grieves [7], the DT was first proposed at his executive course on product lifecycle management (PLM). With technical improvements, the DT was introduced into the aerospace industry by National Aeronautics and Space Administration (NASA) and U.S. Air Force [8]. Accordingly, the space vehicle remaining on Earth could be replaced by a digital mirror model to provide more insights through high-fidelity simulation. Nowadays, the DT has been applied to more fields and has become a much pursued topic.

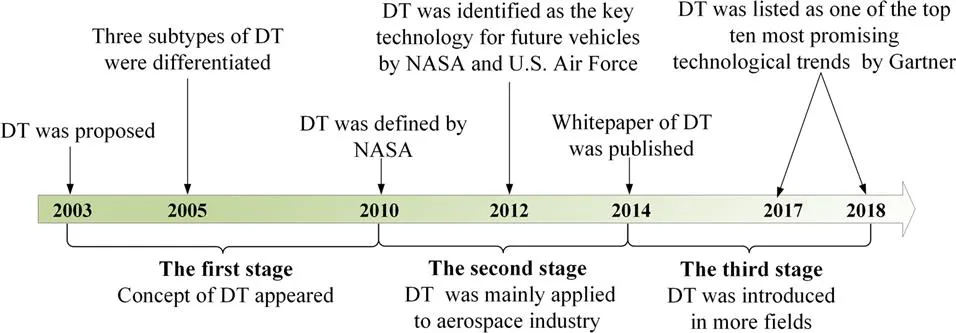

As shown in Fig. 1.1, the short development history of DT can be divided into three stages.

In the first stage, the concept of DT was proposed by Grieves in 2003 according to the Whitepaper written by him [7]. It was defined in three dimensions, including a physical entity, a digital counterpart, and a connection that ties the two parts together [7]. In 2005, Grieves put forward another idea that the DT could be classified into three subtypes, including DT prototype, DT instance, and DT aggregate [9]. However, due to technical and cognitive limitations, there were very few related reports in the following 5 years. Fortunately, during this period, the New IT has emerged and developed, which laid the foundations for the future development of the DT.

In 2010, NASA illustrated the definition and function of DT for space vehicles in detail in the Draft Modeling, Simulation, Information Technology and Processin...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Preface

- Part 1: Background and Connotation

- Part 2: Digital Twin Driven Smart Manufacturing

- Part 3: Digital Twin and New Technologies

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Digital Twin Driven Smart Manufacturing by Fei Tao,Meng Zhang,A.Y.C. Nee in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Mechanical Engineering. We have over one million books available in our catalogue for you to explore.