eBook - ePub

Control of Welding Distortion in Thin-Plate Fabrication

Design Support Exploiting Computational Simulation

- 352 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Control of Welding Distortion in Thin-Plate Fabrication

Design Support Exploiting Computational Simulation

About this book

The intense temperature fields caused by heat sources in welding frequently lead to distortions and residual stresses in the finished product. Welding distortion is a particular problem in fabricating thin plate structures such as ships. Based on pioneering research by the authors, Control of Welding Distortion in Thin-Plate Fabrication reviews distortion test results from trials and shows how outcomes can be modeled computationally. The book provides readers with an understanding of distortion influences and the means to develop distortion-reducing strategies.

The book is structured as an integrated treatment. It opens by reviewing the development of computational welding mechanics approaches to distortion. Following chapters describe the industrial context of stiffened plate fabrication and further chapters provide overviews of distortion mechanics and the modeling approach. A chapter on full-scale welding trials is followed by three chapters that develop modeling strategies through thermal process and thermo-mechanical simulations, based on finite-element analysis. Simplified models are a particular feature of these chapters. A final sequence of chapters explores the simulation of welding distortion in butt welding of thin plates and fillet welding of stiffened plate structures, and shows how these models can be used to optimize design and fabrication methods to control distortion.

Control of Welding Distortion in Thin-Plate Fabrication is a comprehensive resource for metal fabricators, engineering companies, welders and welding companies, and practicing engineers and academics with an interest in welding mechanics.

- Allows practitioners in the field to minimize distortion during the welding of thin plates

- Provides computational tools that can give insight into the effects of welding and fabrication procedures

- Demonstrates how welding distortion in thin plate fabrications can be minimized through design

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Control of Welding Distortion in Thin-Plate Fabrication by Tom Gray,D. Camilleri,N. McPherson in PDF and/or ePUB format, as well as other popular books in Physical Sciences & Mechanics. We have over one million books available in our catalogue for you to explore.

Information

1

Introduction: development of computational welding mechanics approach to welding distortion

Abstract:

The opening chapter contrasts a welding design and fabrication strategy based on trial and error with one that is guided by quantitative welding simulation methods. An outline is given of the main contributing factors to the development of computational welding mechanics as a discipline and the possibilities that such studies offer for interpreting welding phenomena such as distortion during fabrication. The importance of establishing simple models is emphasised and a first mention is made of simplified computational methods. The content of the following chapters is briefly described and the relationships between each of the chapters in the sequence are explained.

Key words

computational welding mechanics; heat flow; computationally efficient; reduced solutions

1.1 Background: control of welding distortion in fabrication practice

Most designers think that welding is related to black magic… A few do try to adjust their designs to help the welding engineers, but when they look into the subject, they find it too confusing and so abandon hope.

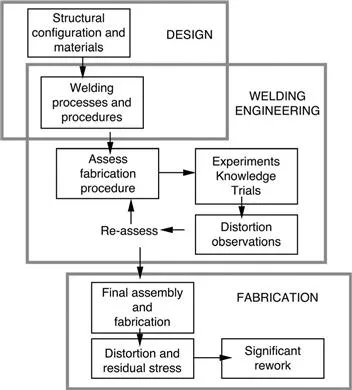

This somewhat defeatist opinion was offered at an international conference in the early 1970s by a senior metallurgist of the Nuclear Power Group. Power plant construction was at its peak in the UK nuclear power industry at that time and the different disciplines involved in welding large structures tended to be applied in a linear and compartmented manner. Figure 1.1 characterises this approach in the context of distortion outcomes. Some engineers operated on the belief that the materials they designed with, including welds, could be treated as homogeneous, isotropic and stress-free.

1.1 Former/existing approach to distortion control.

Metallurgists tended to regard such sweeping assumptions as ignorant and dangerous in the extreme and, on the contrary, sought to elaborate the complexities of metallurgical behaviour around welds. Welding engineers introduced yet another set of new considerations, largely unknown to both structural engineers and metallurgists. There was therefore not much meeting of minds on the subject of how to design welded structures and interaction between structural engineers, metallurgists and welding engineers was largely non-existent.

In this scenario, materials and structural configurations were decided in the first instance by engineers, with specialised input from metallurgists where necessary. There was usually no feedback of information to the primary design process concerning the influence of welding on distortion or residual stress. Such matters might be considered at the later ‘detail design’ stage when the prospective design reached the fabricator, but the approach even then tended to be based primarily on ‘rules of thumb’ or, in better cases, on experience. Again, the opinions and experiences of fabricators were not consistent, as they depended on the different structural contexts, materials and welding processes with which each fabricator might be familiar. At that stage, welding engineers were presented with the problem of identifying suitable assembly, welding and fabrication procedures to minimise distortion, in the context of a largely fixed design configuration and with no means of quantifying likely distortions. Off-line welding trials of some kind were usually undertaken but, for reasons of cost, these tended to be confined to small test specimens designed to provide information on weld outcomes and metallurgy. Such trials would not reflect the large-scale factors present in distortion mechanisms. Hence, much of the ‘experience’ in dealing with distortion was often gained in the context of live production with the consequent penalties of scrapped components and significant rework.

The challenge then, as it remains now, was to recognise relevant knowledge from a variety of disciplines and to apply that knowledge in a properly integrated and quantitative manner. The capability to do that has much improved in the last 40 years, based mostly on new tools to model complex descriptions of manufacturing processes, weld metallurgy and structural behaviour. These are based on increased computational power and integrated physical domains covered by different disciplines. For example, the application of finite-element methods for stress analysis of complex geometries is now well established and this has reduced the need for many approximate and sometimes arbitrary ‘design rules’ previously used in different structural contexts, not least for welds. Typical examples of arbitrary rules might include the concepts of ‘joint efficiency’ and ‘safety factors’, which simply assign a given ‘strength’ to a weld, usually without much quantitative justification. Strength design has instead moved much more towards addressing realistic performance and failure criteria and is now often supported by numerical stress analysis and fracture mechanics modelling.

Analytical treatments of heat flow in welding had certainly been well established by 1970. These treatments are attributed in the literature mainly to the original and independent work of Rosenthal1 and Rykalin.2 Available analytical treatments of heat flow underpinned many strategies used by welding engineers and metallurgists at that time to predict fusion zone sizes, cooling rates and other welding features of interest, although the sources of these treatments and their scope may not always have been evident to the users. Increasing computational power has greatly extended the range of welding phenomena that can now be modelled.

The recent development of ambitious simulation treatments of welding can be traced in the transactions of a series of influential bi-annual international meetings with the title Mathematical modelling of welding phenomena. These began in 19933 and have continued to date. The main topics treated in this series included heat flow, microstructure development, residual stresses and special advanced welding processes. Detailed models of gas flow, weld pool behaviour, solidification and many other phenomena can also be found. The topic of welding distortion appears in the proceedings of the fourth meeting in the series in 1998.4 A new term, ‘computational welding mechanics’ (CWM), appears more often in the literature of this period.

Nevertheless, if there is one area of welding technology that still retains more than a whiff of black magic, it might be the subject of distortion. Nothing is surer than that the use of intense heat sources in fusion welding will generate distortion. This might be accepted if the mode of distortion and the magnitudes could somehow be reliably predicted and allowed for. Even if the relative magnitudes of distortion arising from different fabrication routes could be estimated, the problem might be manageable. However, as will be demonstrated in this book, distortion depends typically on a variety of factors arising in the manufacturing phases, some of them apparently so trivial as to be invisible. Success in minimising distortion therefore requires the very close cooperation of designers, welding engineers and metallurgists – much beyond a mere ‘adjustment’ of designs ‘to help the welding engineers’. The difficulty that has persisted in industry is that there has been little commonly accepted quantitative understanding of what is likely to happen when a structure is welded.

Fortunately, several books have been published in recent years to support improved quantitative understanding. At the risk of missing some useful texts, the following publications are of note.

• Analysis of welded structures by Masubuchi.5 This text, published in 1980, pre-dates the development of CWM as we now know it and much of the data are therefore empirical or qualitative. However, it provides a thorough and extensive review of the literature on welding distortion and residual stress, including standards that might typically be achieved in industrial manufacturing and data describing different practical cases. Chapter 7 (Distortion in weldments) and Chapter 13 (Effects of distortion and residual stresses on buckling strength of welded structures) are particularly useful.

• Welding residual stresses and distortion by Radaj6 deals with computational simulation of temperature fields, residual stress development and the distortions that occur during and after welding.

• Computational welding mechanics by Goldak and Akhlagi7 deals very fully with thermal descriptions, heat input modelling and metallurgical interactions. It is, in general, a practical and useful book for anyone building models of weld processes.

• Computational welding mechanics by Lindgren8 is a practical book aimed at ‘managers and project leaders who want to know what resources are needed to apply the tools of computational welding mechanics and what competence and improvement of processes/products their application can lead to … engineers are given detailed information in order to understand phenomena and design issues as well as guidelines for modelling and simulation’.

• Minimization of welding distortion and buckling, edited by Michaleris9, comprises chapters by different authors and covers basic understanding of welding residual stress and distortion. It includes several techniques for minimising distortion in different practical applications.

• Processes and mechanisms of welding residual stress and distortion is a similar multi-author book, edited by Feng.10 It covers principles and applications, contains useful chapters on measuring temperatures and distortions, and provides thermal simulations for different welding processes and strategies for the control of buckling distortions in plates and shells.

There is therefore much more support now, for those who wish to understand and control welding distortion, than was the case in the 1970s.

Notwithstanding the wealth of information available, a challenging question posed earlier by Murakawa et al.11 is worthy of consideration. They ask ‘is computational welding mechanics truly attractive for people in industry now?’ They conclude that it is not attractive for many and give two reasons to support their claim that ‘computational mechanics is not widely employed in industry’. The first reason is ‘long computational time and the relatively high cost of the nonlinear transient FEM analysis’ (perhaps this is not as serious a problem now as it was even in 1998, when this work was published). The second reason given is ‘a lack of consistent bases to interpret the phenomena and to generalise the knowledge obtained by simulations for broader applications’. In other words, simulations can address specific cases, but can one formulate general design and fabrication strategies from these specifics?

The main answer given in the paper by Murakawa et al. to their own question is to adopt the simplifying concept of ‘inherent strain’. This is in fact very similar to a concept proposed very much earlier (in 1958) by Okerblom, which has not been widely referenced.12 This earlier idea was also the starting point for the ‘computationally efficient’ and ‘reduced solution’ approaches adopted in the present text. As will be shown later, the present authors’ opinion on this point is that some problems can in fact find good solutions using simplified strategies like the ‘inherent strain’ approach, but other problems require more rigorous treatment. A central aim of this book is to identify these different cases.

It is also worth asking a second question, namely: what alternatives are there to welding simulation as a basis for understanding and reducing distortion? A forthright answer to that was given by Okerblom as far back as 1958 and it is as relevant today as it was then – not surprisingly, as his research had been based at the Leningrad Shipbuilding Institute over many years previously and was therefore founded firmly on industrial practice. He states (in translation) ‘In industry, it is usual to make only a qualitative estimate [of distortion] based chiefly on trial-and-error methods, guess work and past experience’. He then spells out in detail, and with specific examples, what the drawbacks are to this ‘usual’ approach – principally, the many departures from specified design measurements and the need for correction of dimensions by further expensive cutting, straightening or bending operations. Okerblom points out that the cost of rectification may be more than that of the original welding of the assembly. These themes are discussed further and brought up to date in Chapter 2.

In summary therefore, the weight of opinion in the literature strongly argues that (using Okerblom’s words)

to minimise distortions and departures from the specified design as a result of welding, a quantitative calculation of the deformations produced during different assembly and welding procedures is necessary

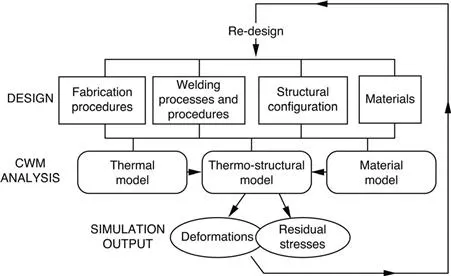

The use of CWM, at some level, provides the only obvious basis for such a quantitative calculation. Figure 1.2 provides a characterisation of this approach. The topic of residual stress is added to Okerblom’s categorisation, because it is highly relevant to the problem of buckling and, also, some methods used to rectify distortion have the effect of adding residual stress fields. Furthermore, the term ‘design’ is conceived more broadly than in Fig. 1.1, to cover any feature of the design or the fabrication process that can be decided in advance.

1.2 Integrated design approach based on CWM.

1.2 Aims: integrated design approach utilising computational welding mechanics (CWM)

The main purpose of this book is thus to provide the guidance necessary to encourage all concerned with thin-plate welded fabrication to establish CWM models appropriate to th...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Author contact details

- Woodhead Publishing Series in Welding and Other Joining Technologies

- Preface

- 1. Introduction: development of computational welding mechanics approach to welding distortion

- 2. Fabrication of stiffened thin-plate structures and the problem of welding distortion

- 3. Tools to deal with welding distortion: predictive modelling and research on in-process techniques

- 4. Understanding welding distortion: thermal fields thermo-mechanical effects

- 5. Computational simulation of welding distortion: an overview

- 6. Experimental investigation of models of welding distortion: methods, results and comparisons

- 7. Modelling thermal processes in welding

- 8. Computationally efficient methods for modelling welding processes

- 9. Finite-element thermo-mechanical techniques for welding distortion prediction

- 10. Simulating welding distortion in butt welding of thin plates

- 11. Simulating welding distortion in fillet welding of stiffened plate structures

- 12. Exploiting welding distortion models: examples of design and manufacturing strategies to optimise fabrication

- Index