- 544 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Introduction to Plant Automation and Controls

About this book

Introduction to Plant Automation and Controls addresses all aspects of modern central plant control systems, including instrumentation, control theory, plant systems, VFDs, PLCs, and supervisory systems. Design concepts and operational behavior of various plants are linked to their control philosophies in a manner that helps new or experienced engineers understand the process behind controls, installation, programming, and troubleshooting of automated systems.

This groundbreaking book ties modern electronic-based automation and control systems to the special needs of plants and equipment. It applies practical plant operating experience, electronic-equipment design, and plant engineering to bring a unique approach to aspects of plant controls including security, programming languages, and digital theory. The multidimensional content, supported with 500 illustrations, ties together all aspects of plant controls into a single-source reference of otherwise difficult-to-find information.

The increasing complexity of plant control systems requires engineers who can relate plant operations and behaviors to their control requirements. This book is ideal for readers with limited electrical and electronic experience, particularly those looking for a multidisciplinary approach for obtaining a practical understanding of control systems related to the best operating practices of large or small plants. It is an invaluable resource for becoming an expert in this field or as a single-source reference for plant control systems.

Author

Raymond F. Gardner is a professor of engineering at the U.S. Merchant Marine Academy at Kings Point, New York, and has been a practicing engineer for more than 40 years.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

Chapter 1

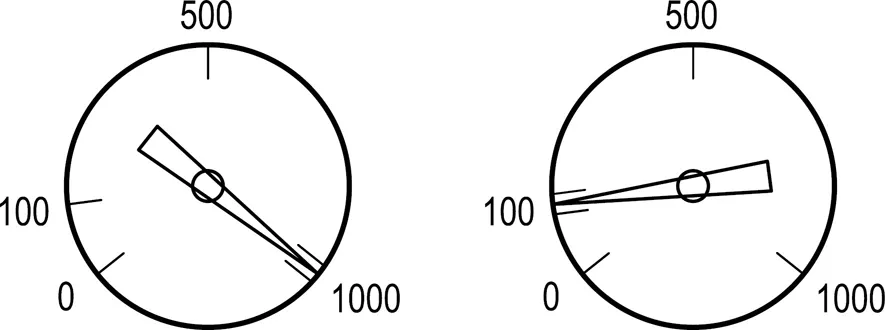

Measurement fundamentals and instrumentation

INSTRUMENTATION DEFINITIONS

GAGE ACCURACY

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Contents

- Preface

- Disclaimer

- Acknowledgments

- Author

- Chapter 1 Measurement fundamentals and instrumentation

- Chapter 2 Control terminology, theory, and tuning

- Chapter 3 Basic electronics

- Chapter 4 Digital theory, logic, and two-state control

- Chapter 5 Motor controllers

- Chapter 6 Variable-frequency drives and harmonics

- Chapter 7 Boiler controls

- Chapter 8 Pump and fan controls

- Chapter 9 Control valves

- Chapter 10 Speed, load, and alternator control

- Chapter 11 Programmable-logic controllers and operation

- Chapter 12 Wiring PLCs and I/O devices

- Chapter 13 Allen-Bradley RSLogix software and ladder-diagram programming

- Chapter 14 Electronic 4–20mA analog signals

- Chapter 15 Analog functions using Allen-Bradley’s RSLogix software

- Chapter 16 IEC 61131-3 PLC programming languages (LD, FBD, SFC, ST, and IF)

- Chapter 17 Centralized control systems, DCS, and SCADA

- Chapter 18 PLC cabling, data transmission, and networking

- Chapter 19 Industrial control system security

- Chapter 20 PLC terms and definitions

- Index