Membrane Technology and Engineering for Water Purification

Application, Systems Design and Operation

- 452 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Membrane Technology and Engineering for Water Purification

Application, Systems Design and Operation

About this book

Membrane Technology and Engineering for Water Purification, Second Edition is written in a practical style with emphasis on: process description; key unit operations; systems design and costs; plant equipment description; equipment installation; safety and maintenance; process control; plant start-up; and operation and troubleshooting. It is supplemented by case studies and engineering rules-of-thumb. The author is a chemical engineer with extensive experience in the field, and his technical knowledge and practical know-how in the water purification industry are summarized succinctly in this new edition.This book will inform you which membranes to use in water purification and why, where and when to use them. It will help you to troubleshoot and improve performance and provides case studies to assist understanding through real-life examples.- Membrane Technology section updated to include forward osmosis, electrodialysis, and diffusion dialysis- Hybrid Membrane Systems expanded to cover zero liquid discharge, salt recovery and removal of trace contaminants- Includes a new section on plant design, energy, and economics

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

Introduction to Membrane Technology

Abstract

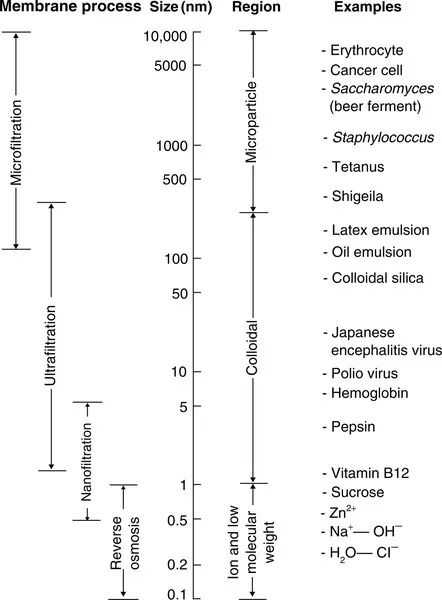

1.1 Technology Overview

1.2 Historical Development

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Dedication

- Preface Two

- Acknowledgements for the Second Edition

- Chapter 1: Introduction to Membrane Technology

- Chapter 2: Water and Membrane Treatment

- Chapter 3: Hybrid Membrane Systems – Applications and Case Studies

- Chapter 4: Hybrid Membrane Plant Design and Operation

- Chapter 5: Design, Energy and Cost Analyses of Membrane Processes

- Chapter 6: Appendix: Engineering Data and Notes

- Index