eBook - ePub

Shape Memory and Superelastic Alloys

Applications and Technologies

- 232 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Shape Memory and Superelastic Alloys

Applications and Technologies

About this book

Shape memory and superelastic alloys possess properties not present in ordinary metals meaning that they can be used for a variety of applications. Shape memory and superelastic alloys: Applications and technologies explores these applications discussing their key features and commercial performance. Readers will gain invaluable information and insight into the current and potential future applications of shape memory alloys.Part one covers the properties and processing of shape memory effect and superelasticity in alloys for practical users with chapters covering the basic characteristics of Ti-Ni-based and Ti-Nb-based shape memory and superelastic (SM/SE) alloys, the development and commercialisation of TiNi and Cu-based alloys, industrial processing and device elements, design of SMA coil springs for actuators before a final overview on the development of SM and SE applications. Part two introduces SMA application technologies with chapters investigating SMAs in electrical applications, hot-water supply, construction and housing, automobiles and railways and aerospace engineering before looking at the properties, processing and applications of Ferrous (Fe)-based SMAs. Part three focuses on the applications of superelastic alloys and explores their functions in the medical, telecommunications, clothing, sports and leisure industries. The appendix briefly describes the history and activity of the Association of Shape Memory Alloys (ASMA).With its distinguished editors and team of expert contributors, Shape memory and superelastic alloys: Applications and technologies is be a valuable reference tool for metallurgists as well as for designers, engineers and students involved in one of the many industries in which shape memory effect and superelasticity are used such as construction, automotive, medical, aerospace, telecommunications, water/heating, clothing, sports and leisure.

- Explores important applications of shape memory and superelastic alloys discussing their key features and commercial performance

- Assesses the properties and processing of shape memory effect and superelasticity in alloys for practical users with chapters covering the basic characteristics

- Introduces SMA application technologies investigating SMAs in electrical applications, hot-water supply, construction and housing, automobiles and railways and aerospace engineering

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Shape Memory and Superelastic Alloys by K Yamauchi,I Ohkata,K. Tsuchiya,S Miyazaki in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Mining Engineering. We have over one million books available in our catalogue for you to explore.

Information

Part I

Properties and processing

1

Mechanisms and properties of shape memory effect and superelasticity in alloys and other materials: a practical guide

K. Tsuchiya, National Institute For Materials Science, Japan

Abstract:

This chapter describes fundamental knowledge about shape memory and superelastic alloys which may be useful to potential users of these alloys. Basic characteristics and properties of various shape memory/superelastic alloys are described in the first and second sections. The mechanisms of the shape memory effect and superelasticity are then explained, followed by a section on thermodynamics which is intended for more proficient readers.

Key words

shape memory effect

superelasticity

stress–strain curve

martensitic transformation

martensite

austenite

R phase

1.1 Introduction

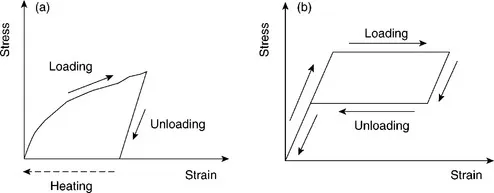

As one of the most prominent functional metallic materials, shape memory alloys (SMAs) are widely used in a range of appliances, from coffee maker thermostats to glasses frames. They have also found an increasing number of applications in the rapidly progressing field of minimally invasive surgery, specifically in the production of medical devices such as stents, guide wires, and filtration devices (Morgan, 2004). It is the shape memory effect (SME) and superelasticity (SE), characteristics unique to SMAs, that make them suitable to these applications. SME and SE are illustrated in the form of stress–strain curves in Fig. 1.1. In SME, a previously deformed alloy can be made to recover its original shape simply by heating (Fig. 1.1(a)); while in SE, the alloy can be bent or stretched to a great extent, but returns to its original shape once the load is released (Fig. 1.1(b)).

Figure 1.1 Stress–strain curves describing (a) shape memory effect and (b) superelasticity.

In the case of SME, shape recovery takes place at a particular temperature, and thus a single piece of material functions both as a sensor and as an actuator. This is the reason why SMAs are often referred to as smart or intelligent materials. Such materials are useful in the production of simple, compact and reliable actuator devices. SMA actuators will be discussed in greater detail in Chapter 5.

SE is suited to applications which require the use of a material with large recoverable deformation. For example, in the case of TiNi wires, it is typically possible to recover approximately 8% strain, which is about 800 times larger than conventional elastic strain (Hooke’s law) in metals. Another important characteristic of superelasticity is its non-linear stressstrain response.

This chapter describes the fundamental properties of SMAs in order to assist the reader in understanding the working principles of a wide variety of SMA applications (such as those described in Parts II and III) as well as to aid and motivate them towards researching and inventing novel applications for these materials.

1.2 Properties of shape memory alloys (SMAs)

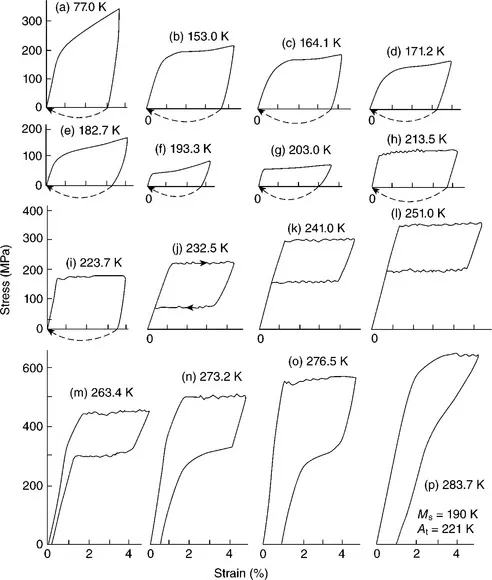

Figure 1.2 consists of a series of tensile stress–strain curves for TiNi, obtained at different temperatures (Miyazaki et al., 1981). It is clear, at a glance, that the properties of SMAs are strongly temperature dependent. At low temperatures, the stress (or load) required to deform the sample is relatively low. Once the load has been removed, the deformation persists, just like a plastic deformation in conventional metals, such as steels or aluminum, but vanishes after the sample has been heated, as indicated by the broken arrows (SME). Above 232.5 K, the deformation stress starts to increase with temperature, and the deformation vanishes upon the removal of the load, even without heating (SE). At higher temperatures, the residual strain appears and the stress–strain curves are more or less similar to those of conventional metals. Stress–strain behavior is not the only property of SMAs to be affected by temperature. Various other properties, such as elastic modulus, electrical resistivity, and specific heats, are also strongly temperature dependent. The reason for such complex behavior is that the sample changes state as the temperature increases, and thus its deformation mechanism is different for various temperature ranges.

Figure 1.2 Tensile stress–strain curves of Ti–50.6Ni obtained at different temperatures (Ms = martensitic transformation start temperature, Af = reverse transformation finish temperature, (Miyazaki et al., 1981).

1.3 Fundamentals of shape memory alloys (SMAs)

1.3.1 Martensitic transformation

Both the SME and SE share a common origin, known as martensitic transformation. Martensitic transformation is a particular class of phase transformation. Most metallic materials and ceramics are crystalline materials in which the constituent atoms are regularly arranged in three dimensions, forming a particular crystal structure representing each phase. The structure of crystalline materials is often altered in response to a change in the external environment, such as a change in temperature, pressure, str...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Contributor contact details

- Preface

- Part I: Properties and processing

- Part II: Application technologies for shape memory alloys (SMAs)

- Part III: Application technologies for superelastic alloys

- Appendix: History of the Association of Shape Memory Alloys

- Index