- 474 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

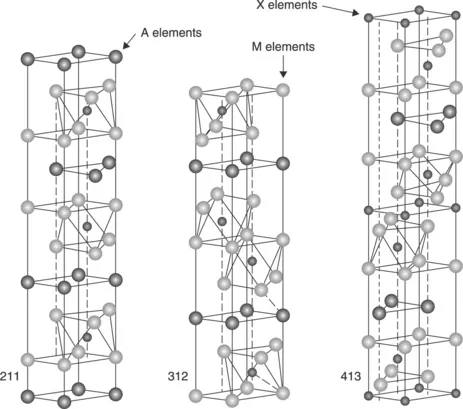

Advances in Science and Technology of Mn+1AXn Phases

About this book

Advances in Science and Technology of Mn+1AXn Phases presents a comprehensive review of synthesis, microstructures, properties, ab-initio calculations and applications of Mn+1AXn phases and targets the continuing research of advanced materials and ceramics. An overview of the current status, future directions, challenges and opportunities of Mn+1AXn phases that exhibit some of the best attributes of metals and ceramics is included. Students of materials science and engineering at postgraduate level will value this book as a reference source at an international level for both teaching and research in materials science and engineering. In addition to students the principal audiences of this book are ceramic researchers, materials scientists and engineers, materials physicists and chemists. The book is also an invaluable reference for the professional materials and ceramics societies.- The most up-to-date and comprehensive research data on MAX phases is presented- Written by highly knowledgeable and well-respected researchers in the field- Discusses new and unusual properties

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

Methods of MAX-phase synthesis and densification – I

Abstract:

1.1 Introduction

1.2 Synthesis methods

1.2.1 Synthesis of powder MAX phases

Pressureless sintering (PS)

Mechanical alloying (MA)

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- List of figures

- List of Tables

- Preface

- About the editor and contributors

- Chapter 1: Methods of MAX-phase synthesis and densification – I

- Chapter 2: Methods of MAX-phase synthesis and densification – II

- Chapter 3: Consolidation and synthesis of MAX phases by Spark Plasma Sintering (SPS): a review

- Chapter 4: Microstructural examination during the formation of Ti3AlC2 from mixtures of Ti/Al/C and Ti/Al/TiC

- Chapter 5: Fabrication of in situ Ti2AlN/TiAl composites and their mechanical, friction and wear properties

- Chapter 6: Use of MAX particles to improve the toughness of brittle ceramics

- Chapter 7: Electrical properties of MAX phases

- Chapter 8: Theoretical study of physical properties and oxygen incorporation effect in nanolaminated ternary carbides 211-MAX phases

- Chapter 9: Computational modelling and ab initio calculations in MAX phases – I

- Chapter 10: Computational modeling and ab initio calculations in MAX phases – II

- Chapter 11: Self-healing of MAX phase ceramics for high temperature applications: evidence from Ti3AlC2

- Chapter 12: Oxidation characteristics of Ti3AlC2, Ti3SiC2 and Ti2AlC

- Chapter 13: Hydrothermal oxidation of Ti3SiC2

- Chapter 14: Stability of Ti3SiC2 under charged particle irradiation

- Chapter 15: Phase and thermal stability in Ti3SiC2 and Ti3SiC2/TiC/TiSi2 systems

- Index