- 734 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Advances in Ceramic Matrix Composites

About this book

Ceramic matrix composites (CMCs) have proven to be useful for a wide range of applications because of properties such as their light weight, toughness and temperature resistance. Advances in ceramic matrix composites summarises key advances and types of processing of CMCs.After an introductory chapter, the first part of the book reviews types and processing of CMCs, covering processing, properties and applications. Chapters discuss nanoceramic matric composites, silicon carbide-containing alumina nanocomposites and advances in manufacture by various infiltration techniques including heat treatments and spark plasma sintering. The second part of the book is dedicated to understanding the properties of CMCs with chapters on Finite Element Analysis, tribology and wear and self-healing CMCs. The final part of the book examines the applications of CMCs, including those in the structural engineering, nuclear and fusion energy, turbine, metal cutting and microelectronics industries.Advances in ceramic matrix composites is an essential text for researchers and engineers in the field of CMCs and industries such as aerospace and automotive engineering.

- Reviews types and processing of CMCs, covering processing, properties and applications

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Advances in ceramic matrix composites: an introduction

I.M. Low Curtin University, Australia

Abstract

Several new types of ceramic matrix composites and their processing techniques have recently been developed. This chapter discusses the development of composites based on MAX phases, geopolymers and cold ceramics. Spark plasma sintering and strong magnetic field alignment are highlighted as emerging techniques for the synthesis and densification of ceramic matrix composites.

Key words

ceramic composites

MAX phases

geopolymers

spark plasma sintering

magnetic field alignment

1.1 The importance of ceramic matrix composites

There is an impending need to develop new stronger and tougher structural materials in order to meet the challenges and demanding needs in materials application for the twenty-first century in diverse strategic fields from building to transportation and energy. Ceramic matrix composites (CMCs) have emerged as potential candidates in view of their excellent physical and mechanical properties. CMCs are heterogeneous materials in which a second phase is embedded within a ceramic matrix. They combine ceramic characteristics (i.e. high strength, hardness and temperature stability) with specific tailored properties (i.e. toughness, self-healing or functional) depending on the nature of the reinforcing phase. The unique ability of CMCs to repair themselves through self-healing of cracks is one of the topics reviewed in this book.

Because of their unique properties, CMCs have proven to be useful for a wide range of applications such as for cutting tools, dental prostheses, thermal barrier coatings, as well as structural materials for the nuclear, energy, military, aerospace and building industries. This book summarizes the latest advances on the types, processing, properties and applications of CMCs. Although much progress has been made over the past ten years in the research and development of CMCs, only a very few new material systems and novel processing techniques have been discovered. Two selected examples of novel CMCs and two emerging processing techniques are described below.

1.2 Novel material systems

1.2.1 MAX phases and composites

MAX phases such as Ti3 SiC2, Ti3AlC2, Ti2AlC, Ti4AlN3, Ti2AlN, Nb4AlC3 and Nb2AlC are a new class of nanolayered, hexagonal ceramics with the general formula Mn+1AXn (where n = 1–3, M is an early transition metal, A is a group A element and X is carbon or nitrogen).1 These compounds represent a new class of solids that combine some of the best attributes of metals and ceramics.2 As such, they are also creep, fatigue and corrosion resistant and have ultra-low friction. With proper alignment of the grains, they also exhibit quasi-plasticity at room temperature. The mobility of dislocations and the multiplicity of shear-induced deformation modes are responsible for the observed plasticity. These ceramics have applications in nuclear research, metallurgy, mining and spaceflight by virtue of their unique properties. For example, both Ti3SiC2 and Ti3AlC2 are candidate fuel-cladding materials in future gas-cooled fast nuclear reactors due to their high radiation resistance. Ti2AlC shows excellent oxidation resistance at intermediate and high temperatures in flowing dry or wet air. For the past decade, the research on MAX phases and their composites has been dominated by Prof. Michel Barsoum and co-workers at Drexel University,1, 2 Prof. Yanchun Zhou and coworkers at the Shenyang Institute of Metal Research3, 4 and Dr Zheng-Ming Sun and co-workers at the Japanese National Institute of Advanced Industrial Science and Technology (AIST).5

1.2.2 Geopolymers and ‘cold’ composites

New environmental regulations, growing global environmental awareness, sustainability and societal concerns have given an impetus for a cradle-to-grave approach in the eco-design of environmentally friendly composite materials. By activating a solid aluminosilicate source with an alkali metal hydroxide or silicate solution, a class of aluminosilicate binders known as geopolymers can be synthesized at near ambient temperatures. These materials have reasonable mechanical properties and good thermal stability but show brittle failure behaviour. Because of their potential as high performance, environmentally friendly replacements for ordinary Portland cement (OPC) in many applications, they are currently attracting widespread attention.

Davidovits6 coined the name ‘geopolymer’ to denote a new polymeric aluminosilicate material that was prepared by reacting a geological mineral (e.g., dehydrated kaolinite clay) with alkali silicate solution under highly alkaline conditions. It has been shown that a wide range of waste aluminosilicate materials may be converted into building materials, as they acquire excellent physical and chemical properties. Solid aluminosilicate sources such as fly-ash, volcanic ash, metakaolin and granulated ground blast furnace slag have been used as source materials. The mechanical properties of geopolymers such as strength and fracture toughness can be further enhanced by incorporating natural or inorganic fibres into the matrix.7 Similarly, the building industry is increasingly obliged to reduce CO2 gas emissions and develop more sustainable building materials or low-energy content materials without firing such as ‘green concrete’ through utilizing natural fibres. In these materials, the quality of the interface between the matrix and the natural fibres dictates their mechanical performance.

1.3 Emerging processing techniques

1.3.1 Spark plasma sintering (SPS)

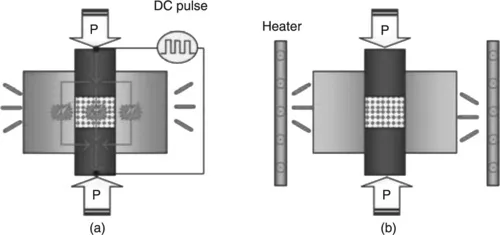

Most advanced non-oxide ceramics such as carbides and nitrides are very difficult to sinter using conventional means because of very strong covalent bonds in their crystal structures and extremely low atomic diffusivity. Spark plasma sintering (SPS) is a novel sintering technique for the densification of ceramic matrix composites. Unlike the conventional sintering techniques such as hot-pressing and hot-isostatic pressing, which require heat generated by an electric current passing through the heating elements, SPS does not require any heating elements (see Fig. 1.1). Instead, SPS generates heat by passing a high-pulsed direct current through a graphite die and the sample to be sintered.8 The SPS process heats the powder compact directly by the pulse arc discharges, thus achieving very high thermal efficiency. As a result, material densification by SPS is generally very fast (i.e. within a few minutes) and can be achieved at temperatures 200 to 500°C lower than those used in conventional sintering. The sintering process is assisted by the use of pressure, which helps the plastic flow of the material as well as the generated plasma, and this serves to accelerate sintering.

1.1 Heating and sintering in (a) spark plasma sintering and (b) hot pressing.8

SPS is currently the most powerful sintering technique available for processing alloys, ceramics, composites and biomaterials. Comprehensive reviews of the apparatus and methods for electric current-activated/assisted sintering (ECAS) have been written by Grasso and co-workers9 and Orrù et al.10

1.3.2 Strong magnetic field alignment (SMFA)

One approach in the quest for new and superior structural materials is by mimicking the architecture of biological materials. Through bio-inspired design, shell-like nanolaminar structures, like that of nacre, with greatly enhanced strength and toughness can be obtained. The...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright page

- Contributor contact details

- Woodhead Publishing Series in Composites Science and Engineering

- 1: Advances in ceramic matrix composites: an introduction

- Part I: Types and processing

- Part II: Properties

- Part III: Applications

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Advances in Ceramic Matrix Composites by I M Low in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Materials Science. We have over one million books available in our catalogue for you to explore.