- 160 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Welded Joint Design

About this book

Based on the European Welding Engineer (EWF) syllabus Part 3 – Construction and Design, this book provides a clear, highly illustrated and concise explanation of how welded joints and structures are designed and of the constraints which welding may impose on the design. It is therefore of value both to the welding engineer and the design engineerMany engineers coming into the profession of welding engineering lack a background in design and construction of welded structures and plant. This book has been written with such engineers very much in mind.The safe performance of a structure relies on materials and methods of fabrication which can respond to the explicit or implicit design requirements. It is essential that the welding engineer has the opportunity of making his specialist input to the design process, and an understanding of the basis of the design will help that contribution to be most effective. It is also important that the practising design engineer acquires a basic knowledge of the relevant aspects of welding to be able to execute satisfactory designs and, equally important, to know when to seek the input of a qualified welding engineer.Designed for both students and practising engineers in welding and design, the book will also be of great value to civil, structural, mechanical and plant engineers. There is also much that will interest test houses, welding equipment and consumable manufacturers, classification societies and steel companies.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

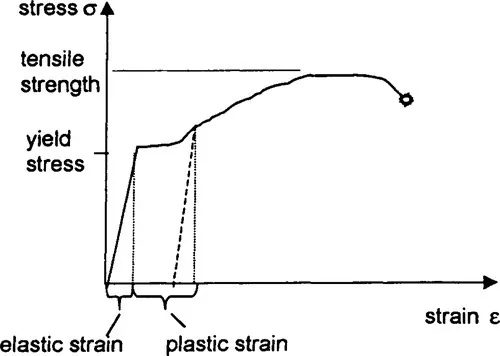

Fundamentals of the strength of materials

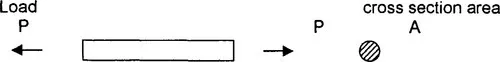

Normal stress

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright page

- Foreword

- Preface

- 1: Fundamentals of the strength of materials

- 2: Stresses in some common types of structures

- 3: Elementary theories of bending and torsion

- 4: Basis of design of welded structures

- 5: Weld design

- 6: Calculating weld size

- 7: Fatigue cracking

- 8: Brittle fracture

- 9: Assessment of structural integrity

- Answers to problems

- Bibliography

- Index

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app