Minimization of Welding Distortion and Buckling

Modelling and Implementation

- 308 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

About this book

Welding is a cost-effective and flexible method of fabricating large structures, but drawbacks such as residual stress, distortion and buckling must be overcome in order to optimize structural performance. Minimization of welding distortion and buckling provides a systematic overview of the methods of minimizing distortion and buckling in welded structures.Following an introductory chapter, part one focuses on understanding welding stress and distortion, with chapters on such topics as computational welding mechanics, modelling the effect of phase transformations on welding stress and distortion and using computationally efficient reduced-solution methods to understand welding distortion. Part two covers different methods of minimizing welding distortion. Chapters discuss methods such as differential heating for minimizing distortion in welded stiffeners, dynamic thermal tensioning, reverse-side heating and ways of minimizing buckling such as weld cooling and hybrid laser arc welding.With its distinguished editor and international team of contributors, Minimization of welding distortion and buckling is an essential reference for all welders and engineers involved in fabrication of metal end-products, as well as those in industry and academia with a research interest in the area.- Provides a systematic overview of the methods of minimizing distortion and buckling in welded structures- Focuses on understanding welding stress and distortion featuring computational welding mechanics and modelling the effect of phase transformations- Explores different methods of minimizing welding distortion discussing differential heating and dynamic thermal tensioning

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

Introduction to welding residual stress and distortion

Abstract:

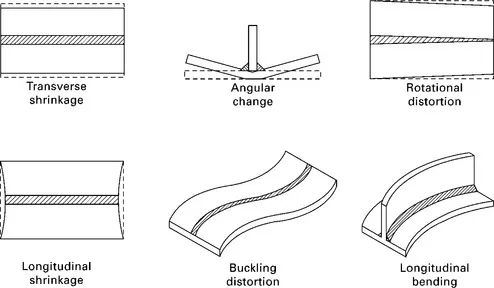

1.1 Types of welding distortion

1.2 Formation of welding distortion

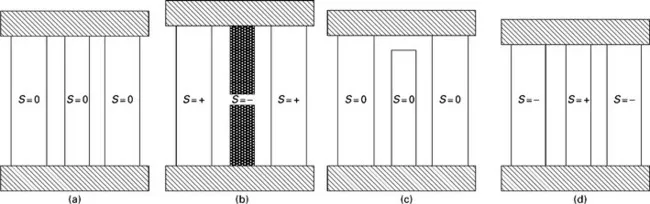

1.2.1 Buckling distortion

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Contributor contact details

- Part 1: Understanding welding residual stress and distortion

- Part II: Minimizing welding distortion

- Index