eBook - ePub

Eco-efficient Masonry Bricks and Blocks

Design, Properties and Durability

- 548 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Eco-efficient Masonry Bricks and Blocks

Design, Properties and Durability

About this book

Masonry walls constitute the interface between the building's interior and the outdoor environment. Masonry walls are traditionally composed of fired-clay bricks (solid or perforated) or blocks (concrete or earth-based), but in the past (and even in the present) they were often associated as needing an extra special thermal and acoustical insulation layer. However, over more recent years investigations on thermal and acoustical features has led to the development of new improved bricks and blocks that no longer need these insulation layers. Traditional masonry units (fired-clay bricks, concrete or earth-based blocks) that don't offer improved performance in terms of thermal and acoustical insulation are a symbol of a low-technology past, that are far removed from the demands of sustainable construction.This book provides an up-to-date state-of-the-art review on the eco-efficiency of masonry units, particular emphasis is placed on the design, properties, performance, durability and LCA of these materials. Since masonry units are also an excellent way to reuse bulk industrial waste the book will be important in the context of the Revised Waste Framework Directive 2008/98/EC which states that the minimum reuse and recycling targets for construction and demolition waste (CDW) should be at least 70% by 2020. On the 9th of March 2011 the European Union approved the Regulation (EU) 305/2011, known as the Construction Products Regulation (CPR) and it will be enforced after the 1st of July 2013. The future commercialization of construction materials in Europe makes their environmental assessment mandatory meaning that more information related to the environmental performance of building materials is much needed.

- Provides an authoritative guide to the eco-efficiency of masonry units

- Examines the reuse of waste materials

- Covers a range of materials including, clay, cement, earth and pumice

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Eco-efficient Masonry Bricks and Blocks by Fernando Pacheco-Torgal,Paulo B. Lourenco,Joao Labrincha,Prinya Chindaprasirt,S Kumar in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Architecture Methods & Materials. We have over one million books available in our catalogue for you to explore.

Information

1

Introduction to eco-efficient masonry bricks and blocks

F. Pacheco-Torgal University of Minho, Braga, Portugal

Abstract

Although masonry units have been used for several millennia they still are and will continue to be widely used construction materials around the world. This chapter provides brief historical facts on masonry bricks and blocks. Brick production data of several countries is included. The contributions of these materials for eco-efficient construction are described. This chapter includes the contribution for the reduction of heat energy needs for buildings, the reduction of embodied energy and also the production of masonry bricks and blocks with the incorporation of industrial wastes. An outline of the book is included.

Keywords

Adobe; Compressed earth blocks; Concrete blocks; Eco-efficient construction; Embodied energy; Energy efficiency; Fired-clay bricks; Masonry; Waste reuse1.1. Brief historical considerations on masonry bricks and blocks: past, present and future

The first masonry units were based on dried mud and were used for the first time around 8000 BC in Mesopotamia, an area bordered by the Tigris and Euphrates rivers stretching from Southeast Turkey, Northern Syria, and Iraq reaching the Persian Gulf (Pacheco-Torgal & Jalali, 2011).

Today, earth masonry units (adobe or compressed earth blocks) still represent a large share of the built environment. Between one-third up to 50 percent of the world's population lives in earth-based dwellings (Guillaud, 2008). The majority of earth construction is located in less developed countries, however, this kind of construction can also be found in Germany, France or even the United Kingdom (Hall, Lindsay, & Krayenhoff, 2012).

As to the fired-clay bricks, their use goes back to around 3000 BC (Lynch, 1994). Even the Roman civilization has left several buildings constructed with fired-clay bricks, for example, the library of Celsus in Ephesus built in 117 AD.

The compressive strength and durability to weathering of fired-clay bricks have made them a widely used construction material for thousands of years. An excellent source on brick history can be found in the book Brick: A World History by Campbell and Pryce (2003). It's worth mentioning that this book has an excessive focus on brick masonry's grand architectural features and is less focused on the engineered aspects of brick masonry. Common clay-fired bricks still serve as the base of recent and amazing buildings (Figure 1.1), highlighting the notorious words of the architect Louis Khan on this building material (Scully, 1993).

With the appearance of Portland cement in the twenty-first century, masonry concrete blocks emerged as an alternative to fired-clay bricks, although the latter are still predominant to a large extent. For instance in the United Kingdom, concrete blocks represent only around five percent of the total masonry units production (Bingel & Bown, 2009).

Because of the high kiln-firing temperatures, the fired-clay industry has high energy consumption and is responsible for high greenhouse gas emissions (GHG). Creation of fired-clay bricks has an energy consumption that is almost 300% higher than the energy consumption of concrete blocks (Reddy & Jagadish, 2003). Taking into account the lower embodied energy of concrete blocks, it's expected that in the future this material will gain a higher market share. Still, masonry fired-clay bricks and concrete blocks are and will continue to be widely used construction materials around the world, even in highly developed countries. According to a report forecast (Freedonia Group, 2010), US demand for fired-clay brick and concrete block products is projected to increase nearly twelve percent annually from a weak 2009 base to 12.4 billion units in 2014 (66% clay bricks and 37% concrete blocks). This represents just a small proportion of the annual worldwide production. Machine-made brick production, using automated kilns, is approximately 125 billion bricks. China alone is responsible for 100 billion units. Around 91% of the total brick production (1391 billion units) concerns handmade bricks. China and India are the major producers of handmade bricks, respectively, with 700 billion and 144 billion units respectively. The remaining countries are responsible for the production of 422 billion units (Habla, 2014; Sabapathy & Maithel, 2013). This leads to the exploitation of hundreds of millions of tons of nonrenewable resources and, to make things worse, in the next decades the brick (and block) demand will continue to rise just because the building construction industry in less developed countries will also rise steadily (until 2030 urban land cover will increase by 1.2 million km2 (Seto, Buneralp, & Hutyra, 2012)) to deal with the dramatic increase of urban population (in the next 40 years, urban population will be about 3000 million people (WHO, 2014)).

1.2. Contributions of masonry bricks and blocks for eco-efficient construction

The concept of eco-efficiency was firstly coined in the book Changing Course (Schmidheiny, 1992) in the context of the 1992 Earth Summit process. This concept includes “the development of products and services at competitive prices that meet the needs of humankind with quality of life, while progressively reducing their environmental impact and consumption of raw materials throughout their life cycle, to a level compatible with the capacity of the planet.”

In the last 10 years, around 1000 papers were published in Scopus journals related to masonry units. The terms “eco-efficiency” or “eco-efficient” were mentioned in only in 0.3% of those papers, meaning that the eco-efficiency concept has not yet successfully entered in the masonry research field. This is especially disturbing in the context of the major environmental threats faced by our planet and the major environmental impacts of the construction industry. Since energy efficiency improvements have the greatest potential of any single strategy to abate global GHG emissions, a major worldwide environmental problem, from the energy sector (IEA, 2012), and since the building sector is a large energy user responsible for about 40% of the European Union's total final energy consumption (Lechtenbohmer and Schuring, 2011), this means that energy efficiency is a priority for eco-efficient construction. The Energy Road Map 2050 (COM (2011), 885/2) confirmed that higher energy efficiency in new and existing buildings is key for the transformation of the EU's energy system. The European Energy Performance of Buildings Directive 2002/91/EC (EPBD) was recast in the form of the 2010/31/EU by the European Parliament on 19 May 2010. One of the new aspects of the EPBD, which reflects an ambitious agenda on the reduction of the energy consumption, is the introduction of the concept of nearly zero-energy building (Pacheco-Torgal, Cabeza, Mistretta, Kaklauskas, & Granqvist, 2013).

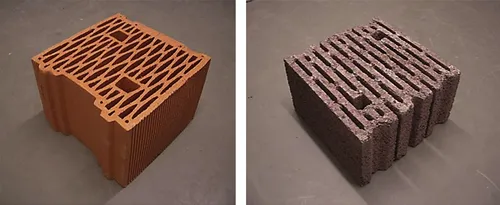

Since walls are the major surface areas of the buildings through which considerable amounts of heat are exchanged between the interior and the external environment, the use of masonry units with improved thermal conductivity contributes to the reduction of heat losses in buildings. Therefore, reducing heat energy needs represents an important contribution for eco-efficient construction. A simple way to achieve that concerns the pore forming technique. It takes advantage of the fact that during the firing stage the combustion of organic matter (sawdust, tobacco residues, grass waste, sawdust, cork dust, paper sludge) leads to the formation of micro-pores. This technique allows for the reduction of the density of fired-clay bricks with organic additions resulting in new bricks with an increased thermal resistance. A more efficient technique encompasses the improvement of the design of the cross-section of masonry units in order to reduce their mass and increase the thermal resistance (minimize their thermal transmittance or U-value). Intense research efforts in this field have turned traditional, thick masonry units into highly perforated ones. This subject is important enough to merit the attention of several chapters in this book. State-of-the-art technology on the cross-section design of fired-clay bricks and lightweight concrete blocks allows single-leaf masonry walls with high thermal performance to be built (Figure 1.2).

In some European countries, these masonry units allow for walls without any additional thermal insulation materials like extruded polystyrene, rigid foam of poly-isocyanurate or polyurethane. These insulation materials are associated with negative impacts in terms of toxicity. Polystyrene, for example, contains antioxidant additives and ignition retardants. Additionally, its production involves the generation of benzene and chlorofluorocarbons. On the other hand, polyurethane is obtained from isocyanates, which are widely known for their tragic association with the Bhopal disaster. Besides, it releases toxic fumes when subjected to fire (Pacheco-Torgal, Fucic, & Jalali, 2012). These masonry units are also specially indicated for load-bearing structures, even those located in areas prone to seismic risks (Lourenço, Vasconcelos, Medeiros, & Gouveia, 2010).

However, as Sandrolini and Franzoni (2010) recognized, energy savings by means of more efficient thermal insulation is an insufficient approach, further suggesting the inclusion of embodied energy as an important parameter for sustainable construction. A recent review by Cabeza et al. (2013) highlights research efforts to develop building materials with less embodied energy. In a future of a near zero operational energy context, the percentage of the embodied energy in the total energy consumption of the buildings will become i...

Table of contents

- Cover image

- Title page

- Table of Contents

- Related titles

- Copyright

- List of contributors

- Woodhead Publishing Series in Civil and Structural Engineering

- Foreword

- 1. Introduction to eco-efficient masonry bricks and blocks

- Part One. Design, properties and thermal performance of large and highly perforated fired-clay masonry bricks

- Part Two. The design, properties and durability of fired-clay masonry bricks containing industrial wastes

- Part Three. The design, properties and durability of Portland cement concrete masonry blocks

- Part Four. The design, properties and durability of geopolymeric masonry blocks

- Part Five. The properties and durability of earth-based masonry blocks

- Part Six. Topology optimization and environmental performance

- Index