- 776 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

About this book

Coal is an important fossil fuel resource for many nations due to its large remaining resources, relatively low production and processing cost and potential high energy intensity. Certain issues surround its utilisation, however, including emissions of pollutants and growing concern about climate change. The coal handbook: Towards cleaner production Volume 1 reviews the coal production supply chain from analysis to extraction and distribution.Part one explores coal characterisation and introduces the industrial use of coal as well as coal formation, petrography, reserves, sampling and analysis. Part two moves on to review coal extraction and preparation. Chapters highlight advances in coal mining technology, underground coal gas extraction, coal sizing, comminution and cleaning, and solid-liquid separation technologies for coal. Further chapters focus on economic factors affecting coal preparation, post-treatment of coal, coal tailings treatment, and the optimisation, simulation and control of coal preparation plants. Finally, part three considers aspects of the coal supply chain including the management approach and individual functions such as coal blending and homogenisation, transportation and handling along the entire supply chain.With its distinguished editor and international team of expert contributors, The coal handbook Volumes 1 and 2 is a comprehensive and invaluable resource for professionals in the coal mining, preparation, and utilisation industry, those in the power sector, including plant operators and engineers, and researchers and academics interested in this field.- Reviews the coal production supply chain from analysis to extraction and distribution- Explores coal characterisation, formation, petrography, reserves, sampling and analysis- Examines coal extraction and preparation and highlights advances in coal mining technology, underground coal gas extraction, coal sizing, comminution and cleaning, and solid-liquid separation technologies

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

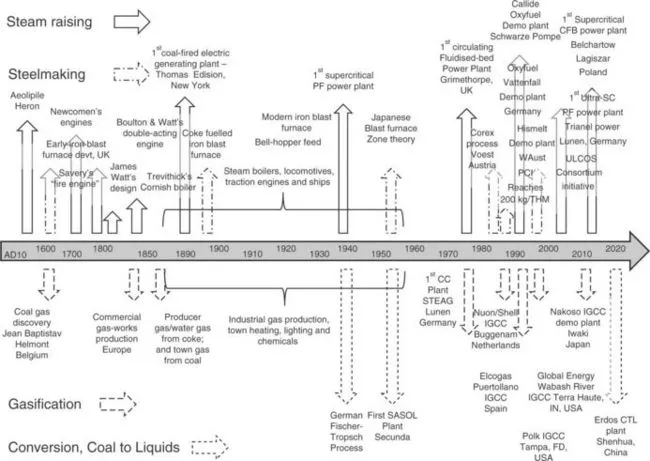

Industrial uses of coal

Abstract:

1.1 Introduction

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Contributor contact details

- Woodhead Publishing Series in Energy

- Foreword

- Preface

- Professor Peter Fečko

- Part I: Introduction and coal characterization

- Part II: Coal extraction and preparation

- Part III: Coal supply chain

- Index