- 632 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Technical Textile Yarns

About this book

Technical yarns are produced for the manufacture of technical textiles. As the range of technical textiles is rapidly increasing, an understanding of the range of yarns available and their properties is important, in order to be able to meet the requirements of the intended end-use.Part one of the book begins by reviewing the advances in yarn production. Topics examine the advances in textile yarn spinning, modification of textile yarn structures, yarn hairiness and its reduction and coatings for technical textile yarns. The second group of chapters describes the range of technical yarns, such as electro-conductive textile yarns, novel yarns and plasma treated yarns for biomedical applications. Technical sewing threads and biodegradable textile yarns are also discussed.Technical textile yarns provides essential reading for yarn and fabric manufacturers, textile scientists, technicians, engineers and technologists, covering a wide range of areas within textile applications. This book will also be an important information source for academics and students.

- Provides a comprehensive overview of the variety of technical textile yarns available along with individual characteristics and production methods

- Documents advances in textile yarn spinning and texturising featuring compact, rotor and friction spinning

- Assesses different types of technical yarns including plasma-treated yarns for biomedical applications and hybrid yarns for thermoplastic composites

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Part I

Advances in textile yarn production

1

Introduction: types of technical textile yarn

R. Chattopadhyay, Indian Institute of Technology, Delhi, India

Abstract:

Yarns which are used for manufacturing technical textile products are known as technical yarns. These yarns are designed primarily to meet some technical requirements of a product. Yarns used for apparel are excluded. Technical yarns have been classified according to their structural form and the raw material used in their manufacture. A brief outline of the production techniques is given. Yarn geometry and response to tensile deformation are discussed. Properties expected from this structure and form are analysed. Application and market potential are also reported.

Key words

technical yarn

technical textile

yarn spinning

yarn structure

yarn property

1.1 Introduction

Textiles have been used for centuries to meet apparel and domestic needs. Uses of textiles in these two sectors are dominant even today. Textiles have also been used to meet various technical functions such as for ropes, sailing cloth, etc. Textile products whose primary objective is to meet some technical requirements or functions are termed technical textiles. Hence, traditional apparel and home textile products are outside the domain of technical textiles. With time, technical usage of textiles has been growing. The development of new fibres and new processing technology is widening the areas of application. Technical textiles have been categorized on the basis of their use in different sectors of the industry and termed agrotech, buildtech, geotech, hometech, indutech, packtech, meditech, sporttech, etc. [1]. The forms in which technical textile products are available are thread, tape, woven, knitted, braided, knotted and non-woven fabric. Of all these forms, only non-woven products are made straight from staple fibres or short natural fibres, whereas for the rest the basic raw material is yarn. The yarns used could be in two different forms: a twisted assembly of continuous filaments or staple fibres, or a parallel assembly of filaments. The yarns are interlaced or looped together to form woven, knitted, braided or knotted products. Sometimes, the slender filaments are first transformed into a bulky yarn and then used in this form in some applications.

1.2 Types of technical yarn

Technical yarns can be classified on the basis of

• source, i.e. raw material, or

• structure and form.

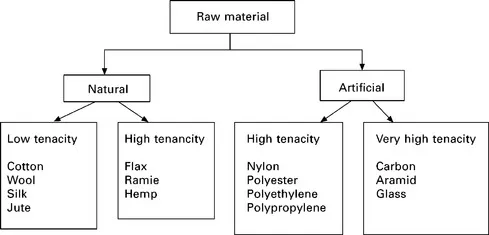

Depending upon the fibre used, they can be classified as natural or artificial, and tenacity-wise further into low, high and very high tenacity yarns (Fig. 1.1). Based on the fibre, the yarns can be designated as cotton, silk, nylon or polyester, Kevlar or carbon fibre yarns. Natural fibre yarns are mostly used in low load-bearing applications. Biodegradability is one of the most important factors favouring the use of natural fibres in many technical applications. Classification on the basis of structure and form is shown in Table 1.1. Yarns can be designated as filament, tape, spun, core spun, plied, braided, etc. It is possible that many yarns may have a dual use in both non-technical and technical applications.

Table 1.1

Classification on the basis of structure and form

| Type | Structure | Form |

| Filament | Monofilament, smooth | Rod-like |

| Multifilament, smooth | Twisted | |

| Untwisted | ||

| Tape | Flat | Twisted |

| Untwisted | ||

| Spun yarn | Uneven surface, hairy | Twisted |

| Core spun yarn | Distinct core and sheath | Core twisted or untwisted |

| Sheath wrapped | ||

| Plied/cabled | Combination of single/plied yarns | Twisted |

| Braided | Combination of single yarns | Interlaced |

1.1 Classification of technical yarns according to raw material.

1.3 Yarn, staple, core spun, plied/folded, cabled and braided yarns

The general characteristics of the yarns classified according to their structure and form are discussed below.

1.3.1 Continuous filament yarns

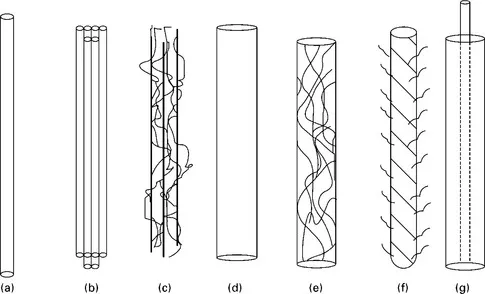

A filament yarn could be of either monofilament or multifilament type.

Monofilament

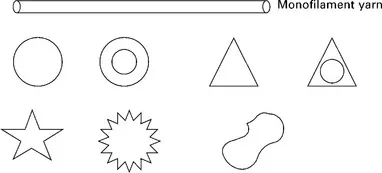

Technical monofilament yarn consists of a single, solid filament having a diameter in the range of 100–2000 μm (0.1–2.0 mm). The cross-sectional shape of the filament can be varied depending upon the end use (Fig. 1.2). It could be circular (Fig. 1.3(a)) or profiled (i.e. triangular, multilobal, serrated, oval, dog-bone), solid or hollow. The surface could be smooth or structured. A non-circular cross-section encourages wicking. The surface area of the fibre increases as the cross-sectional shape becomes more and more non-circular. Monofilaments have high bending rigidity and more resistance to abrasive damage. The diameter of the monofilament depends upon its application.

1.2 Some fibre cross-sectional shapes.

1.3 (a) Monofilament, (b) multifilament, (c) commingled yarn, (d) tape yarn, (e) fibrillated tape yarn, (f) spun yarn, (g) core spun yarn.

Multifilament

A multifilament yarn (Fig. 1.3(b)) is a bunch of thin continuous monofilaments of infinite length. The filaments are assembled together to form a coherent strand through incorporation of a nominal amount of twist known as producer’s twist. The cross-sectional shape of the filaments decides how closely the fibres can be brought together in the yarn. A non-circular cross-section inhibits close proximity between the fibres in the yarn and hence bulky or voluminous yarns are produced from them. Porous polyester fibres with pore radii in the range of 5–1500 μm enable the fibre to absorb water and dry rapidly. Circular fibres promote closeness and therefore give the yarn a lean look. The yarns are smooth, compact, dense and uniform, with maximum fibre strength exploitation. Multifilament yarns are much more flexible than the equivalent monofilament yarns.

Intermingled/commingled yarn

This is essentially a filament yarn. However, instead of twist holding the fibres together, the filaments are intermingled or entangled in order to avoid their separation during processing. When filaments of the same type are entangled, the yarn is known as an intermingled yarn; and when filaments of two or more types, e.g. carbon and polyester, are mingled together, the yarn is known as commingled yarn. The yarn looks tight at the mingle points which are distributed at regular intervals along the yarn length (Fig. 1.3(c)). The mingle points hold the filaments together.

Tape yarns

A tape yarn is basically a thin, narrow, ribbon-like film produced from a synthetic polymeric material such as polyethylene, polyamide or polyester (Fig. 1.3(d)). A flat polymeric sheet or film is sliced into a large number of na...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Contributor contact details

- Woodhead Publishing Series in Textiles

- Part I: Advances in textile yarn production

- Part II: Types of technical yarns

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Technical Textile Yarns by R Alagirusamy,Apurba Das in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Materials Science. We have over one million books available in our catalogue for you to explore.