- 176 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

This book explores the ways in which melt flow behaviour can be exploited by the plastics engineer and technician for increased efficiency of processing operation, control of end product properties and selection and development of polymers for specific purposes. (reissued with minor corrections 1994)

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Polymer Melt Rheology by F N Cogswell in PDF and/or ePUB format, as well as other popular books in Physical Sciences & Fluid Mechanics. We have over one million books available in our catalogue for you to explore.

Information

Chapter One

Fundamental Concepts

In considering the response of thermoplastics during processing we are concerned with three classes of property:

(i) deformation processes, which are necessary to form the product;

(ii) heat and heat transfer, which are necessary to achieve the plastic state;

(iii) chemical and physical change, which may be deliberately induced or adventitious.

1.1 RHEOLOGY

Rheology is the study of deformation and flow: of all the responses of materials it is the one which is most readily felt. We have all squeezed toothpaste tubes, kneaded bread dough or tried to wipe glue from our fingers. Rheology is one way of describing those sensations. For a general introduction to phenomenological rheology an hour in the kitchen is worth more than an hour’s reading, but a general textbook1,2 can usefully be kept at hand.

The fundamentals of rheology are drawn from mechanics3 and provide the support for our study, which is mainly concerned with how materials systems differ from the ideals of classical mechanics. One approach to rheology is to broaden the field of classical mechanics by defining more generalised materials whose properties are derived logically from an equation of state. The great strength of this approach is that it offers full predictive capacity in any deformation history once the equation of state is described by a few appropriate experiments. At the other end of the spectrum lies the view that the interaction between complex materials and complex histories provides a series of unique situations which can only be studied in their own environment. An intermediate course is to analyse the response of a material system in controlled experiments which are qualitatively similar to elements of its processing history and to discover from such experiments what the properties of the material appear to be. This text takes this third approach—the quantification of the ‘feel’ of a material.

Three material states are relevant to polymer processing:

granular —the form in which materials are fed to the process

melt —the form in which they are usually shaped

solid —the form of the final product, but also one in which some shaping may take place

The great majority of this text deals with the rheology of melts, where most of the deformation occurs. However, in illustrating material property data some data on granular and solid response are included where these properties are relevant to processing.

Rheology is concerned with the relationship between stress (defined as force per unit area), strain (defined as change in dimension per unit dimension) and time.

1.1.1 The Geometry of Deformation

There are three simple deformations.

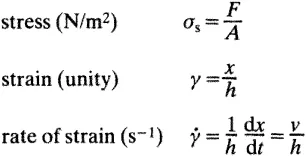

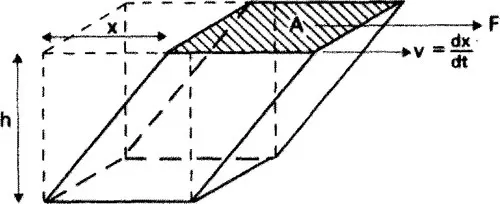

(a) In simple shear the stress is applied tangentially (Figure 1.1):

Figure 1.1 Simple shear: area A and distance h remain constant during deformation

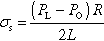

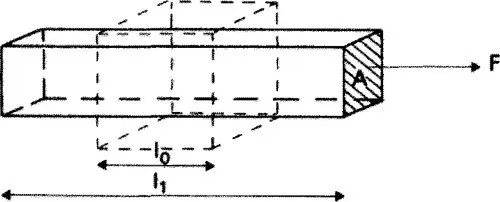

(b) In simple extension the stress is applied normal to the surface of the material (Figure 1.2):

Figure 1.2 Simple extension: cross-sectional area A and sample length l both vary during deformation

(c) In bulk deformation the stress is applied normal to all faces. The stress is the applied pressure, P, and the strain is the change in volume per unit volume, δV/V.

With Theologically complex materials, such as polymer melts, the response to a simple deformation process may be complex. Thus in a simple shearing flow there is not only a shear stress but also a ‘pull along the lines of flow’4 usually described as the normal stress. The practical deformations of polymer processing are themselves usually complex flows compounded of shear, extension and bulk deformations. One solution to this double complexity is to introduce the elegant simplification of tensor notation which is the starting-point of many Theological texts.5 For the purposes of this work it is sufficient to recognise and remember that those complexities exist: with that appreciation it is possible to seek simplifications in the practical response of real materials.

1.1.2 The Rheologicat Response of Materials

There are three types of response to an applied stress: viscous flow, elastic deformation and rupture.

In viscous flow a material continues to deform as long as the stress is applied and the energy put in to maintain the flow is dissipated as heat. Viscosity is defined as the ratio of stress to rate of strain and, in the SI system, has the unit Ns/m2. The viscosities of some common materials are given in Table 1.1.

Table 1.1

Viscosities of some Common Materials

| Viscosity (Ns/m2) | Consistency | |

| Air | 10− 5 | gaseous |

| Water | 10− 3 | fluid |

| Olive oil | 10− 1 | liquid |

| Glycerine | 100 | liquid |

| Golden syrup | 102 | thick liquid |

| Polymer melts | 102–106 | toffee-like |

| Pitch | 109 | stiff |

| Glas... |

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright page

- Dedication

- Publisher’s Note

- Preface

- Notation

- Introduction

- Chapter One: Fundamental Concepts

- Chapter Two: Rheometry for Polymer Melts

- Chapter Three: Physical Features and Flow

- Chapter Four: Rheology and Structure

- Chapter Five: Adventitious Flow Phenomena

- Chapter Six: Rheology in Polymer Processing

- Chapter Seven: Future Developments in Polymer Rheology

- Appendix 1: Additional Sources of Error in Capillary Viscometry

- Appendix 2: Interpretation of Extensional Viscosity from Flow through an Orifice Die

- Appendix 3: The Inference of Elastic Modulus from Post-extrusion Swelling

- Appendix 4: Rupture Behaviour

- Appendix 5: Data Sheet for Capillary Flow

- Appendix 6: Comparison of the Rheological Properties of Two Samples of Low-density Polyethylene

- Appendix 7: Typical Processing Property Data for a General-purpose Low-density Polyethylene Polymer with Moderate Branching

- Appendix 8: Typical Processing Property Data for General-purpose Grade Polypropylene Homopolymer

- Appendix 9: Typical Processing Property Data for a General-purpose Grade Acrylic Polymer

- Appendlix 10: Typical Processing Property Data for an Injection Moulding Grade of 6·6 Nylon at 285°C

- Appendix 11: Typical Processing Property Data for an Injection Moulding Grade of Polyethersulphone

- Appendix 12: Typical Processing Property Data for a Rigid and a Plasticised Grade of PVC

- Appendix 13: Empirical Observations of Flow in Channels of Complex Cross-section

- Appendix 14: Flow through a Tapered Slot or Annular Die to give Uniform Velocity of Extrusion with Varying Thickness Profile

- Author Index

- Subject Index