- 230 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

Custom design, manufacture, and deployment of new high performance materials for advanced technologies is critically dependent on the availability of invertible, high fidelity, structure-property-processing (SPP) linkages. Establishing these linkages presents a major challenge because of the need to cover unimaginably large dimensional spaces. Hierarchical Materials Informatics addresses objective, computationally efficient, mining of large ensembles of experimental and modeling datasets to extract this core materials knowledge. Furthermore, it aims to organize and present this high value knowledge in highly accessible forms to end users engaged in product design and design for manufacturing efforts. As such, this emerging field has a pivotal role in realizing the goals outlined in current strategic national initiatives such as the Materials Genome Initiative (MGI) and the Advanced Manufacturing Partnership (AMP). This book presents the foundational elements of this new discipline as it relates to the design, development, and deployment of hierarchical materials critical to advanced technologies.

- Addresses a critical gap in new materials research and development by presenting a rigorous statistical framework for the quantification of microstructure

- Contains several case studies illustrating the use of modern data analytic tools on microstructure datasets (both experimental and modeling)

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Materials, Data, and Informatics

This introductory chapter sets the stage for the emerging discipline of Materials Informatics at the intersection of materials science, computational science, and information science. Attention is drawn to specific opportunities afforded by this new field in accelerating materials development and deployment efforts. A particular emphasis is placed on materials exhibiting hierarchical internal structures spanning multiple length/structure scales and the impediments involved in establishing invertible process—structure—property linkages for these materials.

Keywords

Data science; informatics; materials design; microstructure; hierarchical materials; process—structure—property (PSP) linkages; materials genome initiative (MGI)

A defining core tenet in the field of materials science and engineering is that the hierarchical internal structure of a material controls completely the macroscale properties or performance characteristics exhibited by the material. Clearly, the overall chemical composition is one of the salient averaged measures of the material structure. However, one can also imagine that even for a fixed overall chemical composition, the internal structures in the material can be dramatically altered through a broad range of manufacturing (also called processing) options (typically involving the application of specific thermomechanical histories). Therefore, since the dawn of human civilization, tremendous effort has been expended in developing or discovering novel processing routes that produced materials with enhanced performance characteristics. Such materials have always served as critical enablers for the successful development of advanced technologies throughout human history [1].

A majority of the materials employed in advanced technologies exhibit hierarchical internal structures with rich details at multiple length and/or structure scales (spanning from atomic to macroscale). Collectively, these features of the multiscale material internal structure are referred to as the microstructure or simply the structure, and constitute the central consideration in the development of advanced hierarchical materials discussed in this book. In this book, these terms (i.e., microstructure or simply the structure) are used very broadly to represent all details of the material internal structure (spanning all relevant length or structure scales involved). Indeed, the representation of the material internal structure in its entirety, even in a single material system, is unimaginably complex and demands very high-dimensional representations. For example, most materials being explored for structural applications (e.g., Ti alloys in jet engines, Advanced High Strength Steels and Mg alloys in lightweight automobiles, Al alloys in aerospace frames, Zr alloys in the nuclear industry) exhibit polycrystalline microstructures at the mesoscale [2–5]. A rigorous description of such material structures should include precise quantification of the spatial distributions of the crystal lattice orientations and various hierarchical defect populations (e.g., point defects, dislocations, grain boundaries, phase boundaries, pores, and microcracks). Given the vast number of tiered spatial distributions that must be quantified to faithfully represent the complex hierarchical microstructure in these material systems, the need for an extremely large-dimensional representation becomes obvious.

Fortunately, the field of materials science and engineering has already taught us that only certain salient features of the material structure dominate the macroscale performance characteristics of interest for any selected application. Therefore, the main challenge in the development of materials with improved/enhanced properties reduces to identifying and tracking the salient microstructure features that are important to a specific engineering or technology application. In other words, the core knowledge needed to guide the materials development efforts can be sought and expressed as reduced-order process—structure—property (PSP) linkages that capture the roles of different unit manufacturing (or processing) steps on the salient microstructure features controlling the properties of interest. It is important to recognize that these linkages represent reduced-order models as they utilize reduced-order representations of the material structure. Historically, such efforts have been largely guided by the scientific approach which entails formulating a fundamental hypothesis and then validating it with carefully designed experiments conducted in highly controlled environments. Such science-driven approaches for establishing PSP linkages have been expensive and slow [6–8], because their focus has been to isolate and study each physical mechanism (i.e., cause) and its associated effect in a highly systematic manner.

In this chapter, we first familiarize ourselves with the main concepts and protocols employed by materials experts in establishing the PSP linkages, along with an understanding of the central challenges involved in these important endeavors. We simultaneously identify specific areas where the emerging concepts in data science and analytics can have a transformative effect in dramatically accelerating these protocols, while reducing the overall cost. We expound these opportunities systematically in the later chapters of this book.

1.1 PSP Linkages

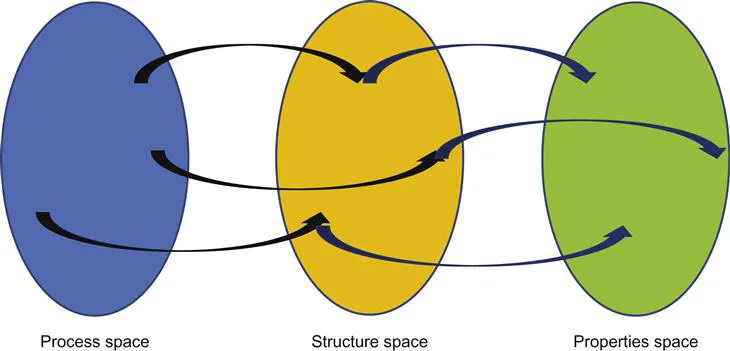

As mentioned earlier, the core knowledge needed to guide the materials development efforts is often expressed as PSP linkages, shown schematically in Figure 1.1 in the direction they are conventionally formulated, that is, from process to material internal structure to properties. It is important to define these terms precisely as they are central to the concepts discussed in this book. In this book, we shall reserve the word space to indicate a complete set, which may typically be exceedingly large. For example, structure space in Figure 1.1 refers to the complete set of all theoretically feasible material internal structures. In other words, any conceivable material internal structure would be an element of this set. Therefore, the structure space shown in Figure 1.1 is unimaginably large. Similarly, a point (or element) in the process space depicts one hybrid process route. A hybrid process route is made up of an ordered sequence of multiple unit manufacturing processes (potentially involving some ordered sequence of refinement, casting, shaping, machining, joining, and finishing steps). Consequently, it is easy to see that one can build an extremely large number of distinct hybrid process routes even when only a few unit processes are considered. In this book, the word property will be used exclusively to refer to physical properties of interest that directly control the performance of a manufactured part. Physical properties are often conceptually defined as characteristics of the material’s physical response to a specified set of idealized driving forces (e.g., thermomechanical loading conditions) imposed on a material. For example, in structural applications, the properties of typical interest include elastic stiffness, yield strength, fracture toughness, and fatigue strength. On a relative scale, the property space is likely to be the smallest of the three spaces depicted in Figure 1.1 but can be high-dimensional when the application demands multifunctional performance requirements.

Historically, the conventional approaches used in the field of materials science and engineering have only explored very limited subspaces in the directions depicted in Figure 1.1. In fact, most of the effort to date has focused on establishing direct linkages between the process and the properties, with token attention paid to the material structure. However, the main difficulty of the conventional approach stems from the fact that the hybrid process space as defined earlier is not a continuous space where we can interpolate with confidence. Since the hybrid process space is made up of a multitude of unit manufacturing steps, any change in the process parameters of any of the steps involved or any change in the sequence of steps would constitute a new hybrid process. If one represents two hybrid processes as two different points in the process space shown in Figure 1.1, the points lying on a straight line connecting these two points cannot be necessarily assigned or associated with meaningful new hybrid processes. As a simple example, consider hybrid process HP1 as a point in the process space denoting an ordered sequence of unit processes as HP1=(P1, P2, P5, P2), where P1, P2, and P5 denote specific unit manufacturing processes. It is emphasized that HP1 is an ordered sequence, starting with P1, followed by P2, and so on. Likewise, one can imagine another point in the process space denoted as HP2=(P6, P5, P9, P1). Now, it should be easy to see that is not easy to assign a new hybrid process to a point half-way between HP1 and HP2. Because interpolation in the hybrid process space is essentially meaningless, the conventional approaches of establishing direct linkages between process and properties have fundamentally employed a discrete approach. Moreover, the traditional approaches have relied heavily on experiments while exploring such highly discretized process histories. Because of these reasons, the rate of discovery of new materials with improved properties has been dreadfully slow. The introduction of the structure space (and the formulation of PSP linkages) has the potential to dramatically alter traditional approaches. Unlike the process space, the structure space allows interpolation because a point in the structure space corresponds to a set of statistical measures of the material internal structure. In other words, interpolated points correspond to structures with interpolated values of the selected structure measures. Also, as the structure space is expected to be a high-dimensional (and unimaginably large) space, it allows for efficient capture and easy visualization of many-to-one connections between the process and the properties of interest. The many-to-one connections imply that it is possible to arrive at distinct structures (exhibiting different statistical measures) through the use of different process routes, while exhibiting the same values for selected macroscale property combinations of interest in an application. It would be very difficult, if not impossible, to capture such subtleties in going directly from the process to the properties.

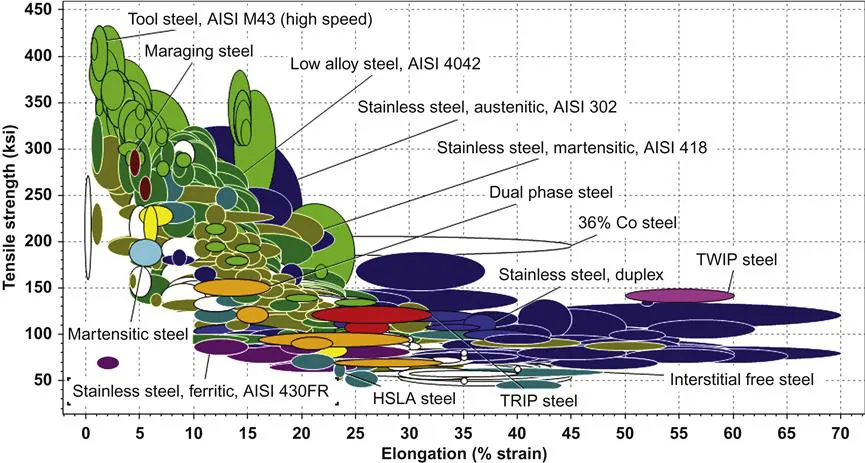

As mentioned earlier, a core tenet in the field of materials science and engineering is that the key to the realization of various material properties needed for advanced technology applications lies in the control of the material internal structure. In practice, this is made very difficult by the fact that the material internal structure is very complex (this will be elaborated later), and its rigorous quantification is likely to benefit immensely from the adoption of modern data science and analytics tools. The main impediment for bringing about the desired digital revolution in the materials development arena lies in the lack of a broadly adopted and broadly applicable framework for the digital representation of the material itself. Historically, it has been a common practice to label a material based on its dominant chemical components. For example, a very large set of materials exhibiting widely different property combinations are simply referred to as steels (more than 3500 grades according to the World Steel Association; http://www.worldsteel.org/) because their chemical composition is dominated by the chemical element Iron. Figure 1.2 summarizes the measured values in steels for a specific property combination of interest in typical structural applications. The reader should take note of the vast range of property values realizable in a single class of metal alloys, namely steels. From the perspective of product design and manufacturing, Figure 1.2 showcases the potential availability of a very large number of material choices in aiding the designer in meeting the customized performance demands in any specific targeted application. The spaces identified in Figure 1.2 would then constitute the design space, as the designer would consider these choices along with a very large number of other available material systems, while also addressing several other performance requirements (could be based on other material properties and/or other design constraints such as cost, environmental impact, etc.). It should be noted that the spaces identified in Figure 1.2 represent only those steels that have been produced and mechanically evaluated to date. The theoretically available design space is expected to be significantly larger, as a very large number of new steels are yet to be produced and tested.

1.2 Material Internal Structure

The main consideration in this book is a systematic framework that can be employed to expand the design space described earlier. Understandably, we must start our discussion with the implicit challenges in uniquely identifying and cataloguing a single material and its associated properties. In this regard, it should be noted that the currently employed material naming conve...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Acknowledgments

- 1. Materials, Data, and Informatics

- 2. Microstructure Function

- 3. Statistical Quantification of Material Structure

- 4. Reduced-Order Representations of Spatial Correlations

- 5. Generalized Composite Theories

- 6. Structure–Property Linkages

- 7. Process–Structure Linkages

- 8. Materials Innovation Cyberinfrastructure

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Hierarchical Materials Informatics by Surya R. Kalidindi in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Materials Science. We have over one million books available in our catalogue for you to explore.