- 310 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Thin Film Coatings for Biomaterials and Biomedical Applications

About this book

Thin Film Coatings for Biomaterials and Biomedical Applications discusses the latest information on coatings, including their historic use by scientists who are looking to improve the properties and biological responses of the material-host interface. Thin films, in particular, are becoming more widely researched and used as an alternative to traditional sprayed coatings because they have a more uniform structure and therefore greater stability.

This book provides readers with a comprehensive guide to thin film coatings and their application in the biomaterials field. Part One of the book details the fundamentals of thin films for biomedical application, while Part Two looks at the special properties of thin films, with a final section reviewing functional thin films and their usage in biomedical applications.

- Provides a comprehensive review on the fundamentals, properties, and functions of thin film coatings for biomaterials

- Covers a broad range of applications for implantable biomaterials

- Written by an international team of contributors who carefully tailor the presented information in a way that addresses industry needs

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Thin Film Coatings for Biomaterials and Biomedical Applications by Hans J Griesser in PDF and/or ePUB format, as well as other popular books in Tecnologia e ingegneria & Biotecnologia in medicina. We have over one million books available in our catalogue for you to explore.

Information

Part One

Fundamentals of thin film technologiesfor biomedical applications

1

Thin film deposition technologies and processing of biomaterials

P.H. Li, and P.K. Chu City University of Hong Kong, Kowloon, Hong Kong, China

Abstract

Surface coating is one of the most effective techniques of surface modification and surface engineering, which is important in biomaterials research and biomedical engineering. Several deposition techniques have been widely studied to deposit thin films and coatings to render desirable biomedical properties. This chapter presents an overview of the fundamentals of selected thin film deposition techniques and pertinent instrumentation with an emphasis on applications to biomaterials.

Keywords

Biomaterials; Deposition; Techniques; Thin film1.1. Introduction

On the heels of continuous biomedical and clinical research and development, high demand is placed on the processing and engineering of biomaterials. Besides the rigorous selection of materials based on their bulk properties, the surface properties of biomaterials are crucial to clinical success. Compared with the development of new biomaterials, modification of selected surface biological and mechanical properties of existing biomaterials to cater to specific needs and applications tends to be more economical and less time-consuming. In particular, deposition of thin films or coatings is a common and effective technique in surface modification and engineering. Methods for thin film deposition can be divided into two groups based on the nature of the deposition process, chemical or physical. Basically, chemical methods such as chemical vapor deposition (CVD) and sol-gel involve gas-phase or liquid-phase chemical reactions whereas physical methods typically include evaporation, sputtering (ejection of materials from a target followed by condensation to form films), and spraying. This chapter presents an overview of the fundamentals of thin film deposition and pertinent instrumentation with an emphasis on applications to biomaterials.

1.2. Chemical vapor deposition

1.2.1. Plasma-enhanced chemical vapor deposition

CVD is a well-understood thin film deposition method that uses chemical reactions of vapor-phase precursors. CVD processes have traditionally been initiated and controlled by heat as the source of energy. An elevated deposition temperature is normally required, which restricts the types of substrates that can be used and coating materials that can be deposited, especially thermally sensitive ones (Jones and Hitchman, 2009). However, thermal energy is not the only energy supplied to the system; plasmas and photons are widely used in CVD processes. Plasma-enhanced chemical vapor deposition (PECVD), or plasma-assisted CVD, is a CVD technique in which plasma in lieu of thermal energy is used primarily to activate ions and radicals in the chemical reactions leading to layer formation on the substrate. One major advantage of PECVD over conventional thermal CVD is that the lower temperature in PECVD allows the deposition of layers that cannot tolerate a high temperature, and temperature-sensitive substrates can be used. Moreover, the deposition rate in PECVD is typically higher and more easily controlled because the precursors activated by the plasma are more reactive and a biased voltage can be applied to control the arrival rate of the ionized precursors (Chu et al., 2004).

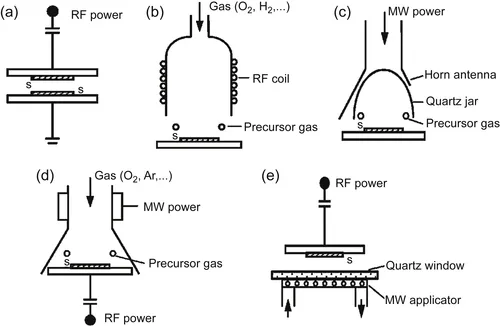

The plasma in PECVD is usually triggered and sustained by radio frequency (RF), microwave (MW), and a combination of these. RF PECVD systems use either internal electrodes or external plasma excitation employing a coil or rings, as illustrated in Fig. 1.1(a) and (b). The frequency used in RF PECVD is commonly between 50 kHz and 13.56 MHz, and operation pressure is between 0.1 and 2.0 Torr. Plasma density is typically between 108 and 1012 cm−3, and the fastest electrons may possess energy as high as 10–30 eV (Kern, 1991; Chu et al., 2004). MW discharge (Fig. 1.1(c)) typically takes place at a MW frequency of 2.54 GHz. Plasma density in the surface wave discharge can be as low as 108 cm−3 in the low-pressure and low-frequency range and can be as large as 1015 cm−3 at atmospheric pressure (Anders, 2000; Chu et al., 2004). There are also dual-mode PECVD systems that apply RF-biased voltage to the substrate holder (Fig. 1.1(d) and (e)).

PECVD has been used industrially for several decades to deposit oxides and nitrides of silicon, polycrystalline silicon, and epitaxial silicon (Tedrow and Reif, 1994) for microelectronics. There are also many applications in the automotive, biomedical, and manufacturing fields (Martinu et al., 2009). Here, the deposition of inorganic or metallic films by PECVD for biomaterials applications is discussed. The PECVD process of polymer films or coatings with organic precursors, termed plasma polymerization, will be discussed in Section 1.2.2.

Figure 1.1 Typical PECVD reactor systems: (a) parallel plate RF PECVD; (b) remote RF PECVD; (c) MW PECVD; (d) remote MW/RF PECVD; (e) dual-mode MW/RF PECVD. Reprinted with permission from Martinu, L., Poitras, D., 2000. Plasma deposition of optical films and coatings: a review. J. Vac. Sci. Technol. A Vac. Surf. Films 18, 2619–2645.

PECVD films have received much attention in the biomedical field, especially silicon-based films such as amorphous silicon (Persheyev et al., 2011), silicon carbide (Bolz and Schaldach, 1990; Daves et al., 2011), and silicon nitride (Wei et al., 2008; Wan et al., 2005). Owing to the wide use of silane (SiH4), these films are typically hydrogenated; for instance, a-Si:H, a-SiC:H, and a-SiN:H. Liu et al. (2007) fabricated hydrogenated amorphous silicon (a-Si:H) films on silicon by PECVD and examined the formation of hydroxyapatite on the surface. The presence of surface Si–H bonds is believed to induce apatite formation, and surface bioactivity is crucial to the development of bioactive silicon-based implants. SiNx:H films with different N/Si ratios have been synthesized and their surface hemocompatibility has been investigated. Improved hemocompatibility is observed in SiNx:H films compared with low-temperature isotropic carbon (LTI-C), and films with more Si–N bonds show less platelet activation, which makes them potentially more blood-compatible than LTI-C and SiNx:H films with fewer Si–N bonds (Wan et al., 2005). Carbon-based films such as diamond-like carbon (DLC) and carbon nitride deposited by PECVD are attracting increasing interest as biomaterials. DLC films are deposited onto silicon by PECVD with methane (CH4) as the precursor; osteoblast adhesion and proliferation tests conducted in vitro reveal that the DLC coating has better surface stability and exhibits improved cellular response (Chai et al., 2008). Ahmed et al. (2012) incorporated fluorine into DLC using acetylene (C2H2) and carbon tetrafluoride (CF4) to control protein adsorption. Their results indicate that adsorption of amino acids is enhanced at low fluorine doping, but a larger fluorine concentration results in reduced adsorption compared with undoped DLC. Fluorine doping of DLC is thus a feasible approach to tailor protein adsorption.

1.2.2. Plasma polymerization

Plasma polymerization, or glow discharge polymerization (Yasuda, 1981), is the proce...

Table of contents

- Cover image

- Title page

- Table of Contents

- Related titles

- Copyright

- List of contributors

- Woodhead Publishing Series in Biomaterials

- Part One. Fundamentals of thin film technologiesfor biomedical applications

- Part Two. Properties of thin films for biomedicalapplications

- Part Three. Functional thin films for biomedicalapplications

- Index