- 256 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Advanced Fiber Spinning Technology

About this book

Translated from Japanese, this book details some of the most interesting developments of the last few decades in the field of fibre manufacture. Many of these have been the result of intensive study in industry and research institutes in Japan - the country at the forefront of research in fibre spinning technology.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Advanced Fiber Spinning Technology by T. Nakajima in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Materials Science. We have over one million books available in our catalogue for you to explore.

Information

1

Fundamentals of spinning

Ken-ichi Katayama Takuma National College of Technology, Takuma-cho, Japan

Masaki Tsuji Institute for Chemical Research, Kyoto University, Japan

There are a great many subjects covered by the heading ‘Fundamentals of spinning’. In this chapter, however, we confine ourselves to a description of the fundamentals of mathematical simulation for spinning and of new findings on structural formation during spinning and fiber structure. This description should be undertaken for each of the three types of spinning: melt spinning, dry spinning and wet spinning. However, we are concerned here mainly with melt spinning because it is the easiest for us to formulate and accordingly its theory is the most sophisticated of the three. The others are described only briefly with literature references to the details. Nevertheless, the authors hope that this short treatise will help the readers to understand other parts of this book.

1.1 Introduction

The viscose rayon method was developed towards the end of the last century and the melt spinning method for synthetic fibers was established in the early part of the 1930s. In the beginning of the history of spinning, progress in spinning technique was mainly made by accumulating empirical facts; that is to say, by repeating a set of procedures such as setting a spinning condition and measuring the resultant properties and structures of the spun fibers. There were few studies on physiochemical changes and on structural formation in the spun fibers between the spinneret and the take-up device. With the rapid advance of the synthetic fiber industry in the 1940s, a strong need arose to understand the basics of the spinning process in order to improve the productivity and quality control of the fibers. Consequently, towards the end of the 1950s, Ziabicki published a series of papers concerning melt spinning in which the spinning process was analyzed mathematically as an engineering problem: the papers served as a powerful incentive to researchers in this field of study. About the middle of the 1960s, Kase and Matsuo1,2 established a method for the quantitative description of the melt spinning process based on hydrodynamics, rheology and the theory of thermal conduction. Subsequently, Katayama et al3 studied structural formation and crystallization during a melt spinning process by using a special model spinning apparatus. From then on, studies in this field have been extensively carried out in Japan and elsewhere and most of the results are to be found in several references.4−9

In melt spinning, we can predict the diameter and temperature and the tension in a running filament if the spinning conditions and the rheological properties of a polymer used in the spinning process are given; the predicted values are, of course, in good agreement with the experimental results. Such a prediction, however, can be made only when no significant crystallization occurs during the spinning process. If crystallization must be taken into consideration, it becomes increasingly difficult for us to carry out mathematical simulation of the quantities mentioned above.

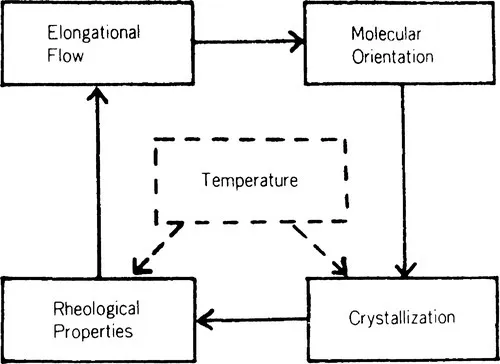

In this case, full quantitative knowledge of the following four points is needed for performing a mathematical simulation of melt spinning:

1 Molecular orientation caused by elongational melt flow.

2 Influence of molecular orientation on crystallization kinetics.

3 Changes in the rheological properties of the polymer caused by molecular orientation and crystallization.

4 Kinetics of non-isothermal crystallization.

The correlation between the above points is shown in Fig. 1.1. In this figure, an arrow indicates that an item from which the arrow starts influences another item to which the arrow is pointing.

1.1 Correlation between factors governing the melt spinning process

In the theory of Kase and Matsuo, mean values of temperature and of stress over the whole area of a transverse section of the filament were used. In the process of high speed spinning, however, the variables such as temperature, stress, orientation and crystallinity must be expressed as functions of the radial distance from the central axis of the filament as well as the distance from the spinneret. For example, consideration of the radial distribution of these variables is inevitable in discussing inhomogenous structures...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright page

- Contributors

- Preface

- Introduction

- Japanese Patents: explanatory note

- 1: Fundamentals of spinning

- 2: Melt spinning

- 3: Solution spinning

- 4: Spinning for nonwovens

- 5: The spinning of highly aesthetic fibers

- 6: Fiber spinning of anisotropic polymers

- 7: Spinning of Thermotropic Liquid-Crystal Polymers

- 8: Gel spinning processes

- 9: Spinning of ultra-fine fibers

- 10: Spinning of optical fibers

- Appendix: Microscopic views of Shingosen

- Index