![]()

1

Introduction

This chapter focuses on the classifications and the technical standards of building materials; it summarizes the characteristics of building materials and their status in construction engineering briefly; and also it introduces the development of building materials.

1.1 Definitions and Classifications of Building Materials

In the general environment for humans’ survival, all the materials or products used in structures or buildings are called building materials which are the material foundation for all the construction engineering. The building materials discussed in this course are all the materials used in building foundations, bases, floors, walls, beams, plates, roofs and architectural decoration.

There is a wide variety of building materials. They are usually classified from different angles for the sake of study, application and description. The most common classifications are based on their chemical components and functions.

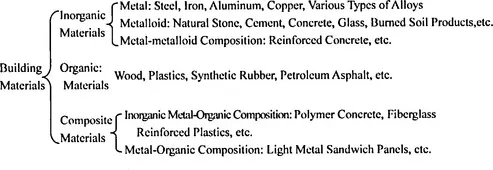

1) According to the chemical components of building materials, they can be classified into inorganic materials, organic materials and composite materials, as follows:

2) According to the functions of materials, they can be divided into structural materials and functional materials:

Structural Materials: mainly used as load-bearing members, such as the materials used for beams, plates and columns.

Functional Materials: mainly possessing some special functions in construction, such as waterproof, ornamental and heat-insulating functions, etc.

1.2 Characteristics of Building Materials and Their Status in Architecture

Building materials are the material foundation for all the construction engineering. Building materials industry which is one of the important basic industries of national economy promotes the development of the construction industry.

Various buildings and structures are constructed by all kinds of building materials on the basis of reasonable design. The varieties, specifications and qualities of building materials are directly related to the applicability, artistry and durability of buildings and also to the cost of projects. A large number of high-quality industrial and civil buildings need to be built for the development of society. Meanwhile, a great deal of water conservancy projects, traffic engineering and port projects need to be built to adapt to the rapid development of the national economy. It requires lots of high-quality building materials which accords with the application environment of projects. Therefore, building materials industry is usually considered as the basic industry for the construction engineering.

Building materials not only have a large consumption, but also are expensive. In the total cost of the construction, the cost of building materials often accounts for about 50 percent. Thus, it is significant to properly choose and reasonably utilize building materials in the construction for the reduction of costs and the improvement of investment benefits.

A large number of new building materials continue to emerge, often promoting the innovation and development of construction techniques. For example, the emergence of clay bricks contributes to the brick-timber structure; the reinforced concrete structure comes from concrete and steel bar; light high-strength materials promote the development of modern buildings and high-rise buildings; the application of various functional materials in the construction industry continues to create diversified comfortable living and production environment and to conserve energy.

In short, the application of building materials in the projects must possess the following characteristics: the function required by projects, the durability proper for the environmental conditions, the rich resources to meet the needs of construction, and low price.

In the building environment, the ideal building materials should be light, high-strength, aesthetic, heat-insulating, sound-absorbing, waterproof, shockproof, fireproof, non-toxic, and efficient, etc.

1.3 The Development of Building Materials

Various building materials form the living environment of human beings, which reflects the cultural and scientific features of each era, becoming an important symbol of humans’ material civilization.

Building materials develop with the improvement of the productivity and living standards. In the early age, human beings inhabited “cave dwelling”. After the Iron Age, they began digging, chipping and logging with simple tools to build shabby houses by natural materials; and with the use of fire, people learned how to burn bricks, tiles and limes, in which way building materials entered the artificial production stage. In 18th and 19th century, steel, cement, concrete and reinforced concrete continuously emerged with the rise of capitalism, the rapid development and the improve of traffic, which pushed building materials into a new stage of development.

Since the 20th century, the formation and development of material science and engineering had contributed to not only the improvement of building materials in function and quality, but also the varieties. Some new building materials with special functions came into being, such as heat-insulating materials, sound-absorbing materials, ornamental materials, heat-resistant and waterproof materials, impermeable materials and wear-resistant, corrosion-resistant, and explosion-proof, and anti-radiation materials, etc. In the second half of the 20th century, building materials evolved towards light, high-strength and functional direction.

In the new century, as humans’ awareness of environmental protection has been strengthened, non-toxic and pollution-free “Green Building Materials” are recommended increasingly and human beings can build their own “Green Home” with new building materials.

1.4 The Introduction of Building Materials’ Technical Standards

The implementing standards should be established for the various techniques of material products because of the scientific management of the modern material production.

Product Standards are the standards established for products to meet some or all the requirements in order to guarantee the applicability of products. They generally includes product specifications, classifications, technical functions, testing methods, rules of inspection and acceptance, packaging, storage, transport and others. For example, cement, ceramic and steel have their own product standards.

Building Material Standards are the technical foundations for the inspection of product quality and the bases for the acceptance of product quality referred to by both sides of supply and demand. The structure designs and construction techniques can be standardized accordingly by the reasonable selection of materials in the construction engineering, which will accelerate the construction and maximize the benefit of the engineering practice.

Recently, there are three categories used in China, as follows:

(1) National Standards

National Standards include mandatory standards (code-named GB), and recommendatory standards (code-named GB / T).

(2) Industry Standards

Industry Standards include the construction industry standards (code-named JGJ), building material industry standards (code-named JC), metallurgical industry standards (code-named YB) and transport industry standards (code-named JT) and so on.

(3) Regional Standards (code-named DBJ) and Enterprise Standards (code-named QB)

The expression of regional standards includes the standard name, the department code, the serial number and the year of approval. For example:

The National Standard (Mandatory), The Hot-rolled Ribbed Steel Bars for the Reinforced Concrete (GB 1499-1998).

The National Standard (Recommendatory), The Decarbonized Hot-rolled Round Coiled Bar (GB/T701-1997).

The Construction Industry Standard, The Design Regulation of Common Concrete Mix Proportion (JGJ55-2000).

The Construction Industry Standard, The Technical Specification of Concrete Structures with Cold-rolled Ribbed Steel Bars (JGJ95-2003).

The Regional Standard of Hebei Province, The Technical Specification for the Application of Modified Gypsum Heat-insulating Mortar [DB13/T(J) 25-2000].

The mandatory standards indicate that any technique (or product) should not fall below the requirements; the recommendatory standards indicate that other standa...