- 248 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Computational Welding Mechanics

About this book

Computational welding mechanics (CWM) provides an important technique for modelling welding processes. Welding simulations are a key tool in improving the design and control of welding processes and the performance of welded components or structures. CWM can be used to model phenomena such as heat generation, thermal stresses and large plastic deformations of components or structures. It also has a wider application in modelling thermomechanical and microstructural phenomena in metals. This important book reviews the principles, methods and applications of CWM.The book begins by discussing the physics of welding before going on to review modelling methods and options as well as validation techniques. It also reviews applications in areas such as fatigue, buckling and deformation, improved service life of components and process optimisation. Some of the numerical methods described in the book are illustrated using software available from the author which allows readers to explore CWM in more depth.Computational welding mechanics is a standard work for welding engineers and all those researching welding processes and wider thermomechanical and microstructural phenomena in metals.

- Highlights the principles, methods and applications of CWM

- Discusses the physics of welding

- Assesses modelling methods and validation techniques

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Introduction

1.1 Computational welding mechanics

The overall aim of computational welding mechanics (CWM) is to establish methods and models that are usable for control and design of welding processes to obtain appropriate mechanical performance of the welded component or structure. It is therefore concerned with subjects ranging from modelling of heat generation and weld pool phenomena, heat flow to thermal stresses and deformations. Material science and constitutive modelling are essential ingredients in the modelling of welding processes due to the severe thermal cycle(s) during welding. CWM models can be combined with models for microstructure evolution and other features that enable the prediction of microstructure, cracking and other phenomena that are determined by the temperature and deformation history of the material.

The centrepiece in welding simulations is the heat generation process. Its description belongs to the domain of thermomechanics in the case of explosive welding, friction welding and friction stir welding. An electrical field is also needed in resistance welding. However, the process becomes much more complex for fusion welding processes. Weld process modelling (WPM) focuses on modelling the physics of heat generation. CWM models, on the other hand, start with a given heat input that replaces the details of the heat generation process and focus on larger scales. The modelling of fluid flow and pertaining convective heat transfer may be integrated with a CWM model. However, the classical approach in CWM is to ignore fluid flow and use a heat input model where heat distribution is prescribed. Thus the heat input model in CWM must be calibrated with respect to experiments or obtained from WPM models. Therefore, the classical CWM models have some limitations in their predictive power when used to solve different engineering problems. For example, they cannot prescribe what penetration a given welding procedure will give. The appropriate procedure to determine the heat input model is therefore important in CWM.

The use of computational models does not replace experimental methods but does mean their role is redesigned. Fewer experiments (tests), are needed to evaluate different design concepts when the power of computer models is applied. Furthermore, the more established simulations become in a given field, the less validation testing is needed. However, more demands are placed on determination of material properties and boundary conditions needed for the computational model.

1.2 Contents of the book

The scope of this book is limited to modelling the thermomechanics of fusion processes of metals. The inclusion of pre- and post-weld heat treatment procedures in the simulation chain is quite natural in this context. The models and methods described in the book can also easily be applied to these procedures. Some examples of simulations where post-weld heat treatment is simulated in conjunction with welding simulations are discussed and the extension of the methods to thermal cutting is also straightforward [1]. The differences between various fusion welding processes in CWM modelling are small. They are accounted for in the heat source models by varying the distribution of energy and the way the addition of the filler material is done.

This introductory part is followed by a description of the multi-physics of welding (Chapter 2), and how to simplify this (Chapter 3), and an illustration of the thermomechanical phenomena to be aware of when modelling welding processes (Chapter 4). Thereafter, Chapters 5 and 6 describe the finite element formulations typically used in CWM. There is more about numerical techniques and modelling techniques for efficient simulations in Chapter 7. In Chapter 8, a methodology for calibration and validation of the models is outlined, followed by a discussion about modelling options in Chapter 9 and a proposal for modelling strategy in Chapter 10. Chapter 11 is concerned with the problem of robustness and stability of a welding process. Chapter 12 provides a short update of earlier reviews of work discussing the improvement of the practice of CWM as well as applications of CWM. Thereafter, the story of successful industrial application of CWM by Volvo Aero is given. The book is closed with the conclusions in Chapter 14.

1.3 The competent company

Competition in a global market drives each company to be efficient and produce products of high quality. ‘Time to the market’ and ‘Right the first time’ are common expressions for this. Combined with development in computational tools and computer hardware, this has led to an increase in the use of tools for virtual design. The finite element method has become an indispensable tool in product development [2].

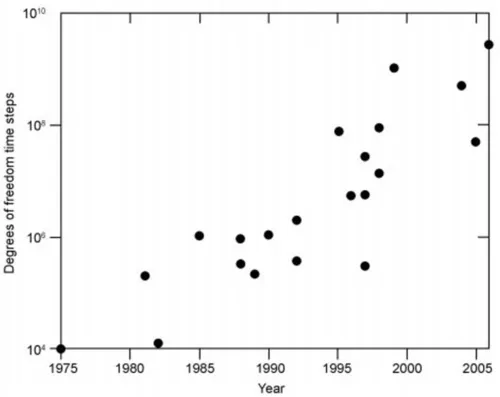

The use of manufacturing simulations is less common because of the difficulties in applying them. However, the problem is not due to a lack of computing power, as is illustrated in Fig. 1.1. The bottleneck for increasing use of advanced simulations is the need for competence! Simulations require competence. This is not only a competence in the use of advanced numerical methods but even more the required quantitative knowledge about processes, materials, etc., needed to set up a model. This requirement is in itself a positive requirement, enforcing the company to understand its manufacturing processes in order to be able to improve them. However, the simulations do not only require competence, they also give competence.

1.1 Size of CWM models. The size is measured as the number of degrees of freedom in the mechanical part of the finite element model multiplied by the number of time steps.

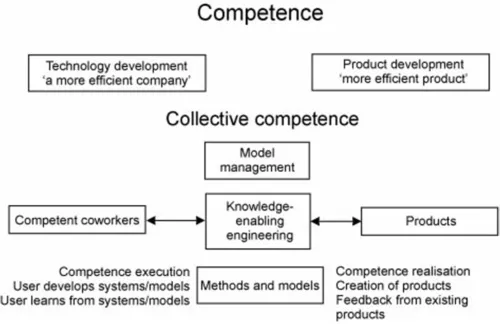

A successful company continuously adapts and develops its internal processes for design, manufacturing, marketing and customer support. The management of human resources and information technology (Fig. 1.2) is crucial in this. Information technology can be used for acquiring, storing and communicating knowledge. Product data management (PDM) systems, product information management (PIM) systems and product lifecycle management (PLM) tools are information technologies used to support product development and also to facilitate teamwork. There is also a need to manage the design process itself. This is done by establishing guidelines for the development of models and their use, together with design criteria. It is preferable to formulate this expertise in written format and also possible to implement it into tools for knowledge-enabled engineering (KEE). These tools can also be combined with systems for model data management and team collaboration.

1.2 The competent company.

CWM belongs to the category of ‘Methods and models’ in Fig. 1.2. Typically, CWM is used in aerospace applications, nuclear power plants and the automotive industry where safety and quality are important. The Volvo Aero story in Chapter 13 illustrates this first case and Volvo Aero’s route to world-class competence in CWM stems from a strategic choice made around 1990. Other companies need results from CWM less often and then outsource the simulations. It is then important to have enough competence in CWM to communicate with the consultant. One example of the latter is a multipass weld case, described by Lindgren et al. [3], where results from CWM were used by a small company to include welding in an application, which reduced their costs considerably.

1.4 Driving forces for increased use of welding simulations

The finite element method is the overall dominant tool used in CWM. The basic equations and finite element formulations, including nonlinear issues, are discussed in Chapters 3, 5 and 6. Although simulations do not replace experiments, as stated earlier, they do offer a number of advantages. It is possible to:

• perform virtual experiments where all parameters can be fully controlled;

• visualise the process;

• design and optimise the welding procedure, fixtures, etc.;

• use the computed fields for subsequent analyses of risk for cracking, etc., or they can be part of the simulation of a manufacturing chain (see Chapter 13).

Welding procedure specifications (WPS) ensure that the quality of a given weld procedure is qualified. This focuses on the integrity of the weld. Test pieces are welded and then checked for defects and cracks. Different set-ups are also used to create more severe thermal stresses in order to check for the risk of cracking. For example, hot cracking can be evaluated by the Varestraint and Transvarestraint test.1

A large number of destructive and non-destructive testing methods can be applied to ascertain the quality of welded components. The use of simulations in addition to these tests enables the evaluation both of residual stresses that affect the life of the welded component as well as of deformations that may hamper the functionality of the component. Simulations become cheaper than testing because of the reduction in cost in computer hardware. This has enabled more complex and therefore more real engineering applications to be simulated (Fig. 1.1).

2

The multi-physics of welding

Modelling of welding processes is an inherent multi-physics problem...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright page

- Foreword

- Preface

- CWM_Lab software

- 1: Introduction

- 2: The multi-physics of welding

- 3: Couplings and reference frames

- 4: Thermomechanics of welding

- 5: Nonlinear heat flow

- 6: Nonlinear deformation

- 7: Numerical methods and modelling for efficient simulations

- 8: Calibration and validation strategy

- 9: Modelling options in computational welding mechanics (CWM)

- 10: Modelling strategy

- 11: Robustness and stability

- 12: The current state of computational welding mechanics (CWM)

- 13: The Volvo Aero story in computational welding mechanics (CWM)

- 14: Summary and conclusion

- References

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Computational Welding Mechanics by Lars-Erik Lindgren in PDF and/or ePUB format, as well as other popular books in Computer Science & Computer Science General. We have over one million books available in our catalogue for you to explore.