The Effect of Creep and other Time Related Factors on Plastics and Elastomers

- 506 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

The Effect of Creep and other Time Related Factors on Plastics and Elastomers

About this book

This reference guide brings together a wide range of critical data on the effect of creep and other long term effects on plastics and elastomers, enabling engineers to make optimal material choices and design decisions. The data are supported by explanations of how to make use of the data in real world engineering contexts and provides the long-term properties data that designers need to create a product that will stand the test of time.This new edition represents a full update of the data, removing all obsolete data, adding new data, and updating the list of plastics manufacturers. Additional plastics have also been included for polyesters, polyamides and others where available, including polyolefins, elastomers and fluoropolymers. Entirely new sections on biodegradable polymers and thermosets have been added to the book.The level of data included – along with the large number of graphs and tables for easy comparison – saves readers the need to contact suppliers, and the selection guide has been fully updated, giving assistance on the questions which engineers should be asking when specifying materials for any given application.- Trustworthy, current data on creep, stress-strain and environmental stress cracking, enabling easier and more effective material selection and product design.- Includes expert guidance to help practitioners make best use of the data.- Entirely new sections added on sustainable and biodegradable polymers, and thermosets.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

Introduction to Creep, Polymers, Plastics and Elastomers

Keywords

1.1 Introduction

1.2 Types of Stress

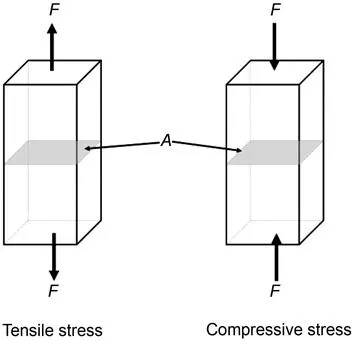

1.2.1 Tensile and Compressive Stress

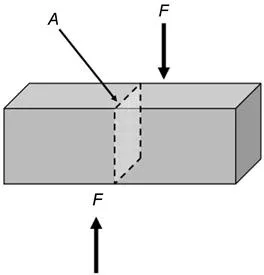

1.2.2 Shear Stress

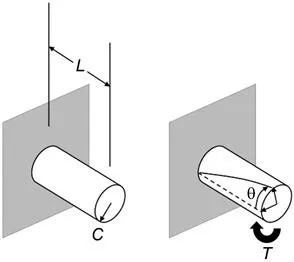

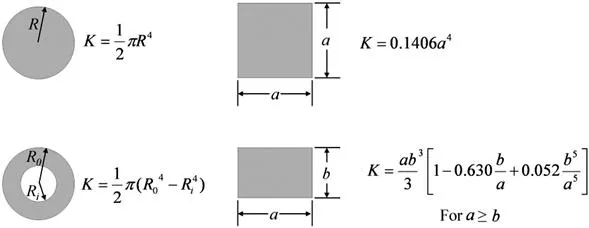

1.2.3 Torsional Stress

1.2.4 Flexural or Bending Stress

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Foreword

- Acknowledgments

- 1. Introduction to Creep, Polymers, Plastics and Elastomers

- 2. Styrenic Plastics

- 3. Polyether Plastics

- 4. Polyesters

- 5. Polyimides

- 6. Polyamides (Nylons)

- 7. Polyolefins and Acrylics

- 8. Thermoplastic Elastomers

- 9. Fluoropolymers

- 10. High-Temperature Polymers

- Appendix 1. Abbreviations

- Appendix 2. Unit Conversion Tables

- Index