- 300 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Introduction to Bioplastics Engineering

About this book

Introduction to Bioplastics Engineering is a practical, user-friendly reference for plastics engineers working with biopolymers and biodegradable plastics that addresses topics that are required for the successful development of cohesive bioplastic products.

While there has been considerable demand for the use of bioplastics in industry, processing these bioplastics is a big challenge. The book provides plastics engineers and researchers with a fundamental, practical understanding of the differences between bioplastics and biodegradable polymers, along with guidance on the different methods used to process bioplastics.

The book also covers additives and modifiers for biopolymers and their effect on properties. Examples include commercial applications of bioplastics, current bioplastics being developed, and future trends in the industry.

This enables engineers, researchers, technicians, and students to understand the decisive relationship between different processing techniques, morphology, mechanical properties, and the further applications of bio-based polymers.

The book presents a true engineering approach for the industry on the processing of biopolymers and biodegradable plastics – discussing the ease of use of the polymer, mechanical and thermal properties, rate of biodegradation in particular environments, and pros and cons of particular bioplastics.

- Enables engineers, researchers, technicians, and students to understand the decisive relationship between different processing techniques, morphology, mechanical properties, and the further applications of bio-based polymers.

- Covers additives and modifiers for biopolymers and their effect on properties

- Includes examples that illustrate the commercial applications of bioplastics, current bioplastics being developed, and future trends in the industry

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Introduction

Abstract

Over the last several years, production of polymers from renewable resources has shown significant growth. Some of the plastics produced from renewable resources such as vegetable oil, corn, and pea starch have been synthesized by microbes and are known as bioplastics. Its development is driven by current demands to replace fossil fuel–based polymers. Limitation in fossil fuel resources, price volatility, impact on the environment, and waste disposal problems are some of the main reasons for this shift toward bio-based plastics. In this chapter, discussion on global bioplastic markets, current material, and market trends and limitation toward biopolymer commercialization will be covered.

Keywords

Bioplastics; bio-based; biodegradable; biodegradability; global markets; global production capacities; biorefinery

1.1 Background

Over the last several years, production of polymers from renewable resources has shown significant growth. Some of the plastics produced from renewable resources such as vegetable oil, corn, and pea starch have been synthesized by microbes and are known as bioplastics. Its development is driven by current demands to replace fossil fuel–based polymers. Limitation in fossil fuel resources, price volatility, impact on the environment, and waste disposal problems are some of the main reasons for this shift toward bio-based plastics.

The use of natural polymers is not a new idea. Fig. 1.1a–c shows natural resins like amber, shellac, and gutta percha that were used during Roman Times and the Middle Ages [1–3]. Native Americans were developing and refining techniques for making ladles and spoons from animal horns long before there was any European contact. Initial development work began in the 1920s when Ford Motor Co. began experimenting with soybeans in the automobiles. However, it all began in the 1940s when Ford Motor Co. gave a go-ahead to produce plastic parts from soybeans to support the idea of sustainability [4].

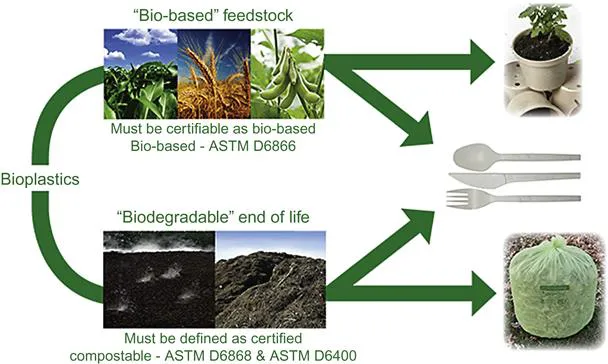

Bioplastics are broadly classified as bio-based and/or biodegradable. When the focus of the material is on the origin of the carbon building blocks and not by where it goes at the end of its product life, it is termed as bio-based. It is important to understand that all bio-based materials are not often characterized as biodegradable, and similarly, not all biodegradable materials are bio-based. Material is considered biodegradable when materials are broken down under the influence of microbes and right conditions and use them as food source. When a complete microbial assimilation of the fragmented food source happens within 180 days in a compost environment, it is considered as compostable. Fig. 1.2 shows pictorial difference between two branches of bioplastics—bio-based and biodegradable, respectively [5,6].

American Society for Testing and Materials (ASTM) developed a standardized test method, ASTM D6866 to determine bio-based content. Originally, developed for the US Department of Agriculture (USDA) Bio-Preferred program, this test method uses radiocarbon dating to determine bio-based contents of materials. Standardized test methods, ASTM D6868 and ASTM D6400, were developed to set specification for compostable plastics [5,7,8].

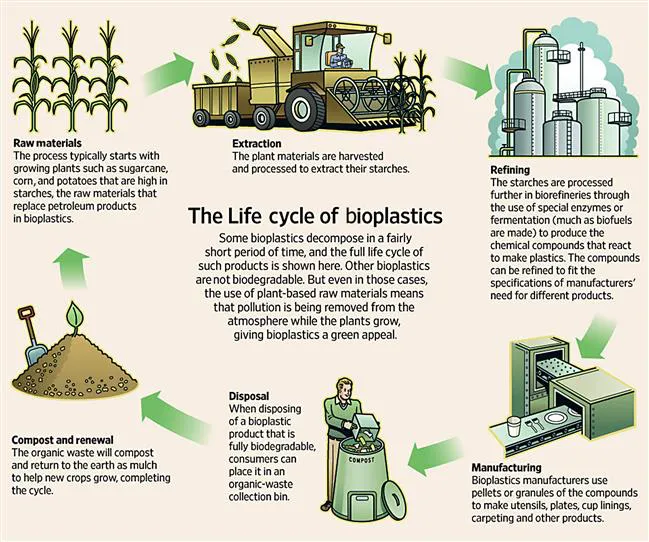

Fig. 1.3 provides an illustration on the life cycle of bioplastics. It all starts with growing plants such as sugarcane and corn that are high in starches. The plants are then harvested and processed to extract their starches. The extracted starches are then refined and fermented using special enzymes producing chemical compound that react to make plastics. Plastics in the form of pellets are used to manufacture products. The product at this stage is fully biodegradable. After its full use, the product is then placed in an organic waste container, which starts the last stage of the cycle [9,10].

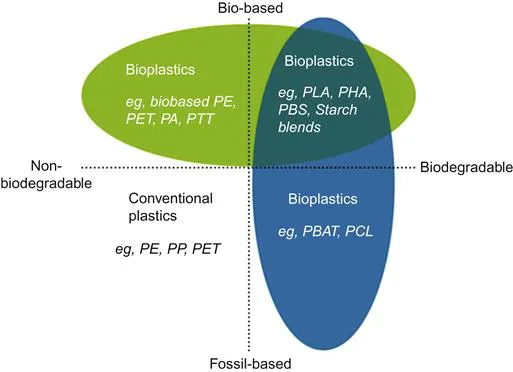

Fig. 1.4 shows material coordinate system to classify type based on their bio-based content and biodegradability. The coordinate system is subdivided into four quadrants: bio-based, biodegradable, fossil-based, and non-biodegradable. Each quadrant represents a group of bioplastics that are classified as follows [11]:

• Group 1 — Bioplastics that are bio-based or partly bio-based non-biodegradable such as bio-based PE, PET, PA, and PTT.

• Group 2 — Bioplastics that are bio-based and biodegradable, such as PLA, PHA, PBS, and starch blends.

• Group 3 — Bioplastics that are fossil-based and non-biodegradable such as conventional PE, PP, and PET.

• Group 4 — Bioplastics that are fossil-based and biodegradable such as PBAT and PCL.

To have sustainable production and consumption, bioplastics have some added benefits. Some of the several advantages are as follows:

• Increase in efficiency

• Renewable resource that can be cultivated annually

• Reduction in carbon footprint

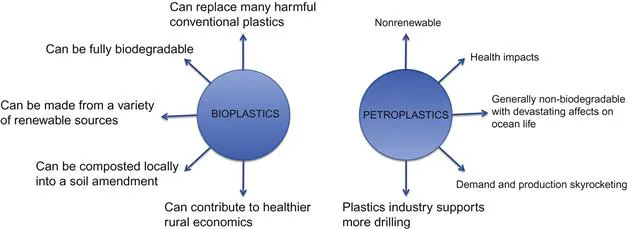

Currently, bioplastics is in infancy and going through growth phase. There are lots of expectations pinned on bioplastics and many aspects have to be evaluated to make the process commercially viable. Cost feasibility is the most important of all however, other factors such as concerns about genetically modified organisms, sustainably grown biomass, composting programs and infrastructure, lack of adequate labeling, and concern over contamination of recycling systems have to be thoroughly understood. Despite all these points, bioplastics have many merits over the petroplastics as shown in Fig. 1.5 [12].

1.2 Understanding Global Markets

Bioplastics are a type of plastic that can be made from natural resources such as vegetable oils and starches. Since bioplastics are plant-based products, the consumption of petroleum for the production of plastic is expected to decrease by 15–20% by 2025. By 2025, Asia and Europe will have the largest share of bioplastics market. Asia will account for 32% while Europe at 31% of the total market followed by the United States at 28%. Currently, bioplastics market growth is at 10% annually covering approximately 10–15% of the total plastics market. This number would increase to 25–30% by 2020 [13].

Nova Institute has done a global survey of 247 corporations covering almost all major bio-based plastics. Based on the survey, they estimate that the bioplastic production capacity will incr...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Dedication

- Preface

- Acknowledgments

- 1. Introduction

- 2. Overview of Biodegradable Polymers

- 3. Mechanisms of Polymer Degradation

- 4. Fundamentals on Biodegradability

- 5. Types of Biodegradable Polymers

- 6. Additives and Modifiers for Biopolymers

- 7. Processing Biodegradable Polymers

- 8. Extrusion of Biopolymers

- 9. Commercial Applications of Bioplastics

- 10. New Developments

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Introduction to Bioplastics Engineering by Syed Ali Ashter in PDF and/or ePUB format, as well as other popular books in Biological Sciences & Biochemistry. We have over one million books available in our catalogue for you to explore.