eBook - ePub

Handbook of Textile and Industrial Dyeing

Principles, Processes and Types of Dyes

- 680 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

Dyeing is one of the most effective and popular methods used for colouring textiles and other materials. Dyes are employed in a variety of industries, from cosmetic production to the medical sector. The two volumes of the Handbook of textile and industrial dyeing provide a detailed review of the latest techniques and equipment used in the dyeing industry, as well as examining dyes and their application in a number of different industrial sectors.Volume 1 deals with the principles of dyeing and techniques used in the dyeing process, and looks at the different types of dyes currently available. Part one begins with a general introduction to dyeing, which is followed by chapters that examine various aspects of the dyeing process, from the pre-treatment of textiles to the machinery employed. Chapters in part two then review the main types of dyes used today, including disperse dyes, acid dyes, fluorescent dyes, and many others for a diverse range of applications.With its distinguished editor and contributions from some of the world's leading authorities, the Handbook of textile and industrial dyeing is an essential reference for designers, colour technologists and product developers working in a variety of sectors, and will also be suitable for academic use.

- Examines dyeing and its application in a number of different industrial sectors

- Deals with the principles of dyeing and techniques used in the dyeing process, as well as types of dyes currently available

- Chapters review various dye types right through to modelling and predicting dye properties and the chemistry of dyeing

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Handbook of Textile and Industrial Dyeing by M Clark in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Chemical & Biochemical Engineering. We have over one million books available in our catalogue for you to explore.

Information

Part I

General aspects of dyeing

1

Fundamental principles of dyeing

M. Clark, University of Leeds, UK

1.1 Introduction

The human race has been interested in colouring materials since prehistoric times typified by the application of natural dyes for furs and textiles. These early dyes were mainly of vegetable origin, with some also of animal origin. Developments extending over many thousands of years led to rather complicated dyeing processes being produced. Among these were woad (natural indigo) which was obtained from the plant Indigofera tinctoria, Tyrian purple which was extracted from the gland of a purple snail and developed by the Phoenicians and Alizarine which was obtained from madder Campeachi wood extract.

The use of picric acid, obtained by Wolfe in 1771 by treating indigo with nitric acid, was subsequently used for dyeing silk yellow, but did not gain any significant attention. In 1856, William H. Perkin succeeded in obtaining a dye he called Mauvine. This was achieved by oxidation of a mixture of aniline bases to produce a violet cationic dye. The brilliant violet hue on silk attracted immediate attention and stimulated other chemists to carry out similar experiments. In this way similar discoveries were achieved; in 1859 Verguin discovered fuchsine, while Griess discovered diazo compounds which led to the development of the currently large class of synthetic dyes, namely the azo compounds. The first true azo dye, Bismark Brown, was developed by Martius in 1863.1

This chapter discusses the principles of dyeing in a general manner, the classification of dyes highlighting specific examples of dye classes. The following chapters will present considerably more detailed discussions regarding textile and industrial dyeing with reference to principles, processes and types of dyes.

1.2 Principles of dyeing

The objective of dyeing is to produce uniform colouration of a substrate usually to match a pre-selected colour. The colour should be uniform throughout the substrate and be of a solid shade with no unlevelness or change in shade over the whole substrate. There are many factors that will influence the appearance of the final shade, including: texture of the substrate, construction of the substrate (both chemical and physical), pre-treatments applied to the substrate prior to dyeing and post-treatments applied after the dyeing process. The application of colour can be achieved by a number of methods, but the most common three methods are exhaust dyeing (batch), continuous (padding) and printing.

1.3 Exhaust dyeing

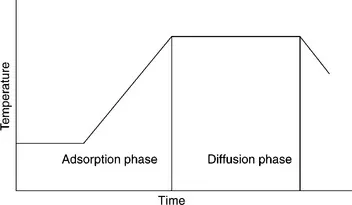

In exhaust dyeing the dye, which is wholly or partially soluble in the dyebath, is transported to the fibre surface by the motion of the dye liquor or by motion of the substrate being dyed. The dye is adsorbed onto the fibre surface and ideally diffuses into the whole of the fibre. Depending upon the dye being used, the interactions between the dye and the fibre can be either chemical or physical. Exhaust dyeing is usually conducted using dilute solutions of dyes, normally termed long liquor dyeing, and can involve liquor to substrate ratios from 8:1 up to 30:1. As described above there are two main phases to exhaust dyeing, the adsorption phase and the diffusion phase. Most exhaust dyeing involves a temperature gradient whereby the dyeing is commenced at a fairly ambient temperature (30–40°C) with the temperature being increased slowly up to a final temperature which is dependent upon the dyes being used (Fig. 1.1).

1.1 Typical dyeing profile.

Depending upon the dyes being used, during the diffusion phase, changes to the dyebath pH may be made to facilitate covalent fixation of the dye which has diffused into the substrate.

Exhaust dyeing recipes, including auxiliaries together with the dyes, are traditionally made up by percent weight relative to the weight of substrate being dyed. The auxiliaries are introduced first into the dyebath and allowed to circulate to enable uniform concentration throughout the dyebath and on the substrate surface. The dyes are then introduced into the dyebath and again allowed to circulate before the temperature is raised in order to obtain a uniform concentration throughout the dyebath. Gaining uniform concentrations of both auxiliaries and dyes is paramount since non-uniform concentrations on the substrate surface can lead to unlevel dye uptake. The speed of dye uptake (exhaustion) of individual dyes can vary and will depend upon their chemical and physical properties together with the type and construction of substrate being dyed. The dyeing rate also depends upon the dye concentration, the liquor ratio, temperature of the dyebath and the influence of the dyeing auxiliaries. Rapid exhaustion rates lead to unlevelness of dye distribution over the substrate surface, so dyes have to be carefully selected when used in multi-dye recipes; many dye manufacturers produce information stating which dyes from their ranges are compatible to achieve level build-up of dye during dyeing. Dyers wish to achieve the highest exhaustion possible to minimise dye remaining in the effluent and increase batch to batch reproducibility, whilst still obtaining the shade required by the customer. The dyeing process will eventually end in equilibrium, whereby the dye concentration in the fibre and the dyebath do not change significantly. It is envisaged that dye adsorbed onto the substrate surface has diffused into the whole of the substrate resulting in a uniform shade required by the customer and that there is only a small concentration of dye left in the dyebath. This is where the final shade of the substrate is checked against the standard. If there is any deviation from the required shade, small additions of dye may be made to the dyebath to achieve the required shade.

Dyers wish to achieve the correct shade the first time of dyeing in order to minimise further processing and reduce costs. In order to do this uniform dyeing rates and high exhaustion rates of dyes are required. To achieve short dyeing cycles, thereby maximising production, most modern dyeing equipment is enclosed ensuring that the dyebath is maintained at the required temperature and that there are no temperature variations within the dyebath. Some dyeing machines can be pressurised enabling the dye liquor to be heated to 130°C allowing substrates, such as polyester...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Contributor contact details

- Woodhead Publishing Series in Textiles

- Part I: General aspects of dyeing

- Part II: Dye types and processes

- Index