- 416 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Microstructure Evolution in Metal Forming Processes

About this book

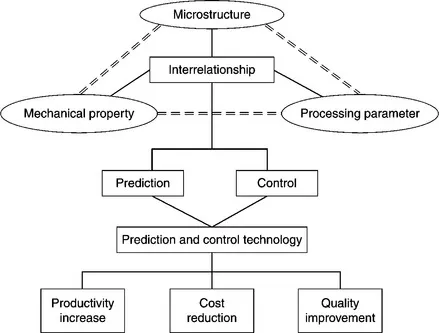

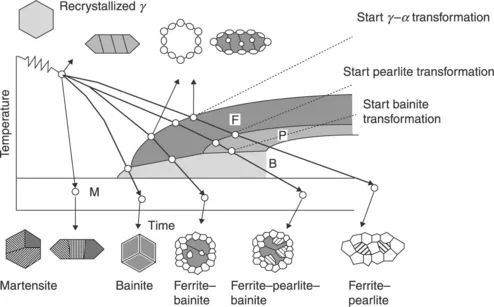

Monitoring and control of microstructure evolution in metal processing is essential in developing the right properties in a metal. Microstructure evolution in metal forming processes summarises the wealth of recent research on the mechanisms, modelling and control of microstructure evolution during metal forming processes.Part one reviews the general principles involved in understanding and controlling microstructure evolution in metal forming. Techniques for modelling microstructure and optimising processes are explored, along with recrystallisation, grain growth, and severe plastic deformation. Microstructure evolution in the processing of steel is the focus of part two, which reviews the modelling of phase transformations in steel, unified constitutive equations and work hardening in microalloyed steels. Part three examines microstructure evolution in the processing of other metals, including ageing behaviour in the processing of aluminium and microstructure control in processing nickel, titanium and other special alloys.With its distinguished editors and international team of expert contributors, Microstructure evolution in metal forming processes is an invaluable reference tool for metal processors and those using steels and other metals, as well as an essential guide for academics and students involved in fundamental metal research.- Summarises the wealth of recent research on the mechanisms, modelling and control of microstructure evolution during metal forming processes- Comprehensively discusses microstructure evolution in the processing of steel and reviews the modelling of phase transformations in steel, unified constitutive equations and work hardening in microalloyed steels- Examines microstructure evolution in the processing of other materials, including ageing behaviour in the processing of aluminium

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Understanding and controlling microstructural evolution in metal forming: an overview

Abstract:

1.1 Introduction

1.2 How microstructure evolves in metal forming

1.2.1 Recovery

1.2.2 Recrystallization

1.2.3 Grain growth

1.2.4 Transformation

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Contributor contact details

- Part I: General principles

- Part II: Microstructure evolution in the processing of steel

- Part III: Microstructure evolution in the processing of other metals

- Index

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app