Optimizing Decision Making in the Apparel Supply Chain Using Artificial Intelligence (AI)

From Production to Retail

- 256 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Optimizing Decision Making in the Apparel Supply Chain Using Artificial Intelligence (AI)

From Production to Retail

About this book

Practitioners in apparel manufacturing and retailing enterprises in the fashion industry, ranging from senior to front line management, constantly face complex and critical decisions. There has been growing interest in the use of artificial intelligence (AI) techniques to enhance this process, and a number of AI techniques have already been successfully applied to apparel production and retailing. Optimizing decision making in the apparel supply chain using artificial intelligence (AI): From production to retail provides detailed coverage of these techniques, outlining how they are used to assist decision makers in tackling key supply chain problems. Key decision points in the apparel supply chain and the fundamentals of artificial intelligence techniques are the focus of the opening chapters, before the book proceeds to discuss the use of neural networks, genetic algorithms, fuzzy set theory and extreme learning machines for intelligent sales forecasting and intelligent product cross-selling systems.- Helps the reader gain an understanding of the key decision points in the apparel supply chain- Discusses the fundamentals of artificial intelligence techniques for apparel management techniques- Considers the use of neural networks in selecting the location of apparel manufacturing plants

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

Understanding key decision points in the apparel supply chain

Abstract:

1.1 Introduction

1.2 Selection of plant locations

1.3 Production scheduling and assembly line balancing control

1.3.1 Production scheduling

1.3.2 Assembly line balancing control

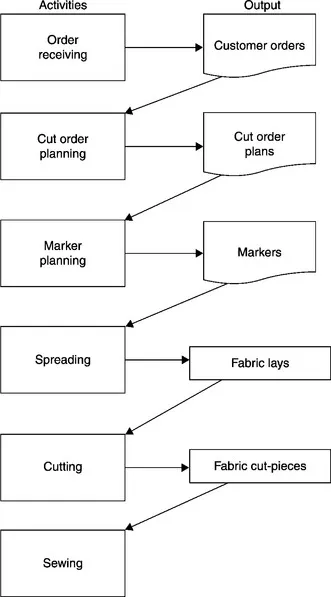

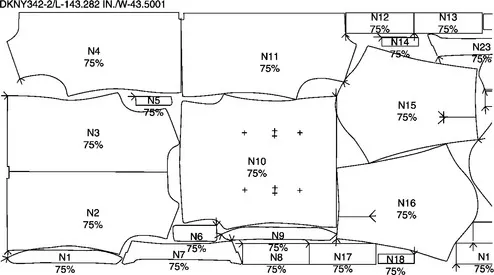

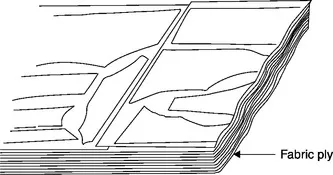

1.4 Cutting room

1.4.1 Cut order planning

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Woodhead Publishing Series in Textiles

- Preface

- Acknowledgements

- Chapter 1: Understanding key decision points in the apparel supply chain

- Chapter 2: Fundamentals of artificial intelligence techniques for apparel management applications

- Chapter 3: Selecting the location of apparel manufacturing plants using neural networks

- Chapter 4: Optimizing apparel production order planning scheduling using genetic algorithms

- Chapter 5: Optimizing cut order planning in apparel production using evolutionary strategies

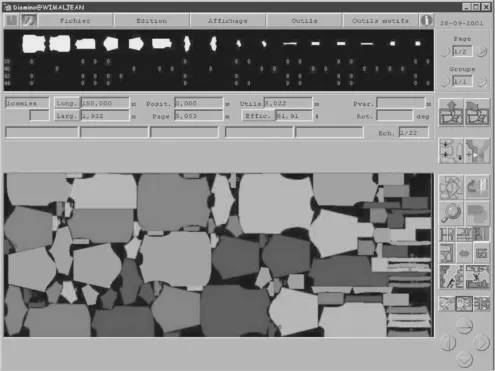

- Chapter 6: Optimizing marker planning in apparel production using evolutionary strategies and neural networks

- Chapter 7: Optimizing fabric spreading and cutting schedules in apparel production using genetic algorithms and fuzzy set theory

- Chapter 8: Optimizing apparel production systems using genetic algorithms

- Chapter 9: Intelligent sales forecasting for fashion retailing using harmony search algorithms and extreme learning machines

- Chapter 10: Intelligent product cross-selling system in fashion retailing using radio frequency identification (RFID) technology, fuzzy logic and rule-based expert system

- Index