- 336 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Pultrusion for Engineers

About this book

Pultrusion for engineers is a comprehensive overview of the latest developments and applications for this growing and increasingly important area of the fibre reinforced plastics industry.Trevor Starr is well known as a specialist consultant with many year's experience in the FRP world. He has assembled an international panel of distinguished experts to provide the widest possible coverage of the state-of-the-art in novel pultrusion applications and development including many leading US researchers such as Brandt Goldworthy, regarded by many as the father of modern pultrusion.Because this book is one of very few to cover pultrusion, it is essential reading for industrial producers of pultruded profiles, chemical companies producing resins and composite materials specialists eager to reach the new markets in, for example, civil engineering that are rapidly being opened up to design solutions involving pultrusions.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Composites and pultrusion

Trevor F. Starr; Jaap Ketel

1.1 Composites

Introduction

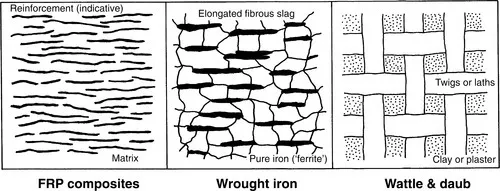

‘Composites’ are arguably the world’s oldest materials that humans have made to answer their particular needs. The Bible, Exodus, Chapter 5, records the use of straw in the making of clay bricks and there is equally good evidence that the ancient Egyptians knew how to spin crude glass fibres and form them with naturally occurring resins into decorative articles. Both examples record utilising the principle of all composite materials, the ability to strengthen – or reinforce – a weaker or brittle material, by the simple addition of another having a fibrous nature (Fig. 1.1).

1.1 Typical composite materials

Much later in history came ‘wattle and daub’, a loose or interwoven collection of either twigs (or, later, formed timber laths) coated with clay (but, eventually, plaster), which was extensively employed in the construction of walls and ceilings. Then came another composite, wrought iron, where the elongated fibrous slag inclusions effectively strengthened the surrounding pure iron matrix, by reducing its otherwise high ductility. Much more recently, and still an important and very necessary construction material, there is reinforced concrete. Here the internal critically designed, interlaced ‘fibrous’ network of steel rods, enhances the mechanical properties of the surrounding cement, sand and aggregate matrix, whose factory or on-site cast shape provides the desired building or construction component. Now, to some irony, that steelwork is beginning to meet a serious competitor in the form of a lightweight, non-corrosive reinforcement network constructed instead from ‘rebars’ based on profiles produced by pultrusion. That fabrication technique is just one of several well-established ways by which today’s ‘composites’ – formerly called reinforced plastics, and often known with growing generic inaccuracy as ‘Fibreglass’ or by such acronyms as ‘GRP’ (glass reinforced polymer) and ‘FRP’ (fibre reinforced polymer) – can be critically manufactured, or moulded, to shape.

The wide application and track-record success of these composites, the development and commercialisation of which began barely 60 years ago, are therefore founded on the age-old, well-established and recognised technology of all composite materials: on the use of a fibrous reinforcement to markedly improve the properties of the matrix in which that reinforcement is distributed and contained. The result is a homogeneous - but totally unalloyed – mixture of normally only two, completely dissimilar materials which confer their distinct properties to each other without the loss of separate identity or characteristic.

Thus in the case of these reinforced plastics, or composites, the unchanged fibrous reinforcement adds its immense strength to the durable, chemical and corrosion-resistant properties of a surrounding polymeric matrix which may be either thermoset or, increasingly over recent years, thermoplastic-based. Their steady and continuous development now boasts world-wide industrial importance and virtually continuous positive growth, typically well in excess of the respective country’s gross domestic product.

Market and application

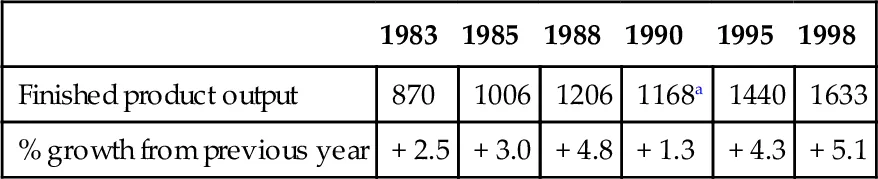

Although trading fluctuations obviously occur, that remarkable growth pattern is suitably exemplified for the United States in Table 1.1. Further, the discipline of composites technology, whether through manufacture or product acceptance example, has extended to virtually every corner of the world. The total 1998 output of that world-wide industry has been estimated as 5.5 × 106 tonnes, valued at US$143 × 109, rising respectively to 7.0 × 106 tonnes and US$205 × 109 by 2005.1

Table 1.1

Growth of the composites industry in the USA over 25 years (tonnes × 1000)

| 1983 | 1985 | 1988 | 1990 | 1995 | 1998 | |

| Finished product output | 870 | 1006 | 1206 | 1168a | 1440 | 1633 |

| % growth from previous year | + 2.5 | + 3.0 | + 4.8 | + 1.3 | + 4.3 | + 5.1 |

Source: Composites Institute, The Society of the Plastics Industry, USA.

a Growth fell in 1989 (− 4.1%) and 1991 (− 8.4%).

To provide just a number of diverse examples from a selection of well over 50000 distinct components that have been identified, glass fibre reinforced thermoset-based composites,2 can be used for the moulding of modular designed construction-site housing and offices, as well as for permanent accommodation such as can be found, for example, near the Arctic Circle in Canada’s Frobisher Bay, or for smoothly contoured enclosures on tracked vehicles in the Antarctic. Equally they may find application for temporary–permanent concrete shuttering in the Far East; for switch-gear cabinets and railway carriage components throughout Australia; or in the assembly of complex medical equipment manufactured in the United States; for ducting, chemical processing equipment and building cladding panels in the UK or for pleasure craft plying the Mediterranean or for pipes and water storage tanks in the Middle East.

When joined in that same quantification by thermoplastic-based versions, composites can be employed for automotive, truck and bus components irrespective of their country of manufacture; for a wide variety of armour and defence equipment produced by European suppliers, or as a final example, for the control surfaces ‘carried’ around the world by aircraft. This can all be further confirmed by Table 1.2 which demonstrates the current percentage share breakdown over the nine market classifications which for a number of years have been employed to quantify the US composites industry.

Table 1.2

Percentage market share in the USA for 1998

| Aerospace/military: Cargo containers, control surfaces, internal fittings, window masks, galley units and trolleysa | 0.6 |

| Appliance/business: Covers, enclosures and fittings, frameworks and panelling | 5.5 |

| Construction: External and internal cladding, pre-fabricated buildings, kiosks, enclosures, structural and decorative building elements, bridge elements and sections, quay facings, signposts and street furniture | 20.8 |

| Consumer products: Components for domestic and industrial use, sanitary ware, sporting goods, swimming pools, notice boards, theme park items | 6.3 |

| Corrosion-resistant equipment: Chemical plant, linings, oil industry components, pipes and ducts, grid flooring, staging and walkways, process and storage vessels | 11.8 |

| Electrical/electronic: Internal and external aerial components and fittings, generation and transmission components, insulators, switch boxes, distribution poles and posts, ladders and cableways | 10.0 |

| Marine: Canoes, boats, yachts, workboats, window masks and internal/external fittings for ferries and cruise liners, buoys, lifeboat and rescue vessels, surf and sailboards | 10.1 |

| Transportation: Automotive, bus, camper, truck and vehicle components and fittings generally, land and sea containers, seating, railway signalling components, enclosures | 31.6 |

| Unclassified: Not otherwise classified | 3.3 |

Source: Composites Institute, The Society of the Plastics Industry, USA.

a Examples are indicative only.

Reasons for using composites

There are many reasons for the wide acceptance of composites by the professional architect, civil and consulting engineer, designer, purchase manager, specifier and other disciplines serving, for example, the aerospace, agricultural, defence, domestic, engineering, industrial, infrastructure, leisure and marine market sectors.

The following can be considered as the ‘standard’ properties, typically exhibited by these FRP composites; the majority are equally applicable to pultruded profiles:

• high strength at low weight;

• moulding to close dimensional tolerances, with their retention under inservice conditions;

• good impact, compression, fatigue and electrical properties;

• ability to reduce part assembly markedly;

• excellent environmental resistance;

• ability to fabricate massive one-piece mouldings;

• proven in-service track record;

• low-to-moderate tooling costs;

• cost-effective manufacturing processes;

• ability to build in, ex-mould tool, both colour and texture decoration;

• particularly attractive in-service life costs.

The following additional properties can readily be provided by reinforcement and/or matrix alteration, chemical addition or other formulation, material or fabrication alteration:

• excellent chemical and corrosion resistance;

• high ultraviolet radiation stability;

• good-to-excellent fire hardness;

• good structural integrity;

• good thermal insulation;

• ability to attenuate sound;

• respectable abrasion resistance;

• ready bonding to dissimilar materials;

• medium-to-high productivity rates.

However, above all these properties, which are clearly attractive to the user, composites have one unique ability that is not pos...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright page

- Dedication

- Preface

- Contributors

- Pultrusion terminology

- Pultrusion and associated companies

- 1: Composites and pultrusion

- 2: The pultrusion process

- 3: Profile design, specification, properties and related matters

- 4: Thermoset resins for pultrusion

- 5: Reinforcements for pultrusion

- 6: Pultrusion applications – a world-wide review

- 7: Infrastructure – a positive market

- 8: The future – beyond 2000

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Pultrusion for Engineers by T. Starr in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Materials Science. We have over one million books available in our catalogue for you to explore.