- 608 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Failure Analysis and Fractography of Polymer Composites

About this book

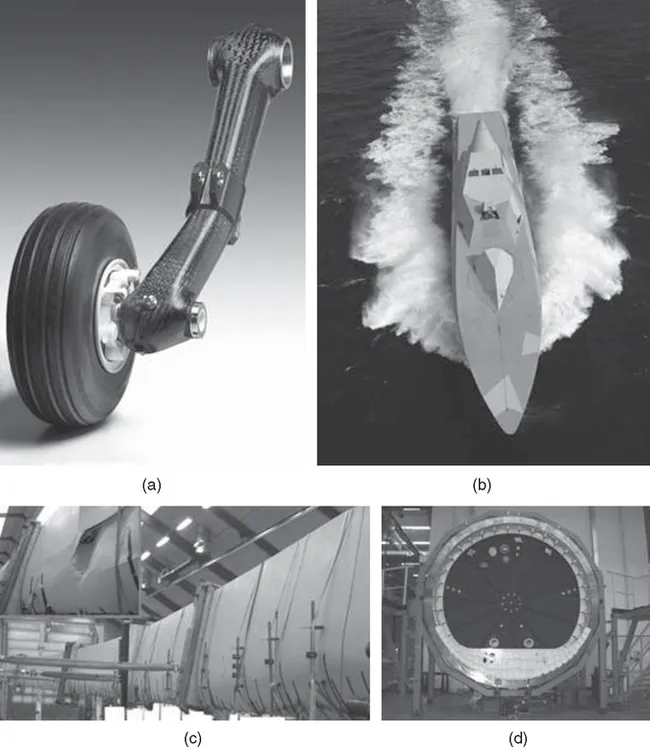

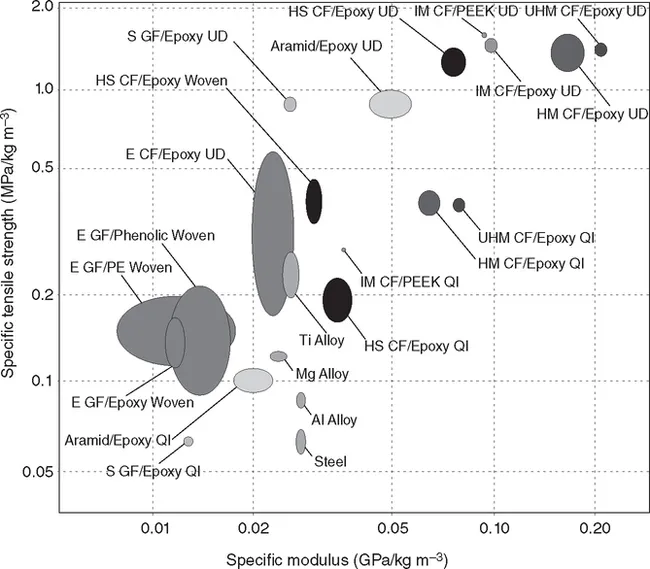

The growing use of polymer composites is leading to increasing demand for fractographic expertise. Fractography is the study of fracture surface morphologies and it gives an insight into damage and failure mechanisms, underpinning the development of physically-based failure criteria. In composites research it provides a crucial link between predictive models and experimental observations. Finally, it is vital for post-mortem analysis of failed or crashed polymer composite components, the findings of which can be used to optimise future designs.Failure analysis and fractography of polymer composites covers the following topics: methodology and tools for failure analysis; fibre-dominated failures; delamination-dominated failures; fatigue failures; the influence of fibre architecture on failure; types of defect and damage; case studies of failures due to overload and design deficiencies; case studies of failures due to material and manufacturing defects; and case studies of failures due to in-service factors.With its distinguished author, Failure analysis and fractography of polymer composites is a standard reference text for researchers working on damage and failure mechanisms in composites, engineers characterising manufacturing and in-service defects in composite structures, and investigators undertaking post-mortem failure analysis of components. The book is aimed at both academic and industrial users, specifically final year and postgraduate engineering and materials students researching composites and industry designers and engineers in aerospace, civil, marine, power and transport applications.- Examines the study of fracture surface morphologies in uderstanding composite structural behaviour- Discusses composites research and post-modern analysis of failed or crashed polymer composite components- Provides an overview of damage mechanisms, types of defect and failure criteria

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

Introduction to failure analysis and fractography of polymer composites

Abstract

1.1 Background

1.2 Introduction to polymer composites

1.2.1 Definition of a composite and composite architecture

Table of contents

- Cover image

- Title page

- Table of Contents

- Related titles

- Copyright

- Dedication

- Author contact details

- Chapter 1: Introduction to failure analysis and fractography of polymer composites

- Chapter 2: Methodology and tools for failure analysis of polymer composites

- Chapter 3: Fibre-dominated failures of polymer composites

- Chapter 4: Delamination-dominated failures in polymer composites

- Chapter 5: Fatigue failures of polymer composites

- Chapter 6: The influence of fibre architecture in the failure of polymer composites

- Chapter 7: Defects and damage and their role in the failure of polymer composites

- Chapter 8: Case studies: failures due to overload and design deficiencies

- Chapter 9: Case studies: failures due to material and manufacturing defects

- Chapter 10: Case studies: failures of polymer composites due to in-service factors

- Index