- 448 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Functional Nanofibers and their Applications

About this book

Nanofibers are a flexible material with a huge range of potential applications in such areas as technical textiles. Functional nanofibers and their applications summarises key trends in the processing and applications of these exciting materials.Part one focuses on the types and processing of nanofibers. Beginning with an overview of the principles and techniques involved in their production, it goes on to review core-shell, aligned, porous and gradient nanofibers. The processing and application of composite functional nanofibers, carbon and polymer nanofiber reinforcements in polymer matrix composites, and inorganic functional nanofibers are then explored in detail, before part one concludes with a consideration of surface functionalization.A wide variety of functional nanofiber applications are then reviewed in part two. Following consideration of their use in filtration, drug delivery and tissue engineering applications, the role of functional nanofibers in lithium-ion batteries, sensor applications, protective clothing, food processing and water purification is explored. Discussion of their use in sound absorption, electromagnetic wave attenuation and biomedical and microelectronic applications follows, before a final discussion of future trends.With its distinguished editor and international team of expert contributors, Functional nanofibers and applications is a key text for all those working in the fields of technical textiles, as well as areas using nanofibers such as composites, biomaterials and microelectronics.

- Summarises key trends in the processing and applications of functional nanofibres in areas such as technical textiles

- Provides an overview of the principles and techniques involved in the production of nanofibres and reviews core-shell, aligned, porous and gradient nanofibres

- Considers the use of nanofibres in filtration, drug delivery and tissue engineering applications and the role of functional nanofibres in lithium-ion batteries, sensor applications, protective clothing, food processing and water purification

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Functional Nanofibers and their Applications by Q Wei in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Materials Science. We have over one million books available in our catalogue for you to explore.

Information

Part I

Types and processing

1

Nanofibers: principles and manufacture

Q. Wei, D. Tao and Y. Xu, Jiangnan University, China

Abstract:

Nanofibers possess many unique properties, which enable them to be used for many different applications. Various techniques have been explored to produce nanofibers. Electrospinning has been recognized as one of the most efficient techniques for producing polymer nanofibers. This chapter briefly reviews the techniques used to make nanofibers, including the key principles of electrospinning. The use of solution electrospinning and melt electrospinning to fabricate polymer nanofibers is also discussed.

Key words

electrospinning

nanofibers

solution

melt

1.1 Introduction

Nanofibers offer small pore sizes and large surface areas with novel and significantly improved physical, chemical and biological properties as the fiber diameter decreases to nanolevel. Hence, nanofibers have attracted a tremendous amount of attention over the past few decades.

Various techniques have been tried to produce polymer nanofibers. Ondarcuhu and Joachim (1998) demonstrated that nanofibers could be drawn with ultimate dimensions comparable with those of single-wall carbon nanotubes by a process similar to dry-spinning. It was also reported that the nanofiber could be positioned precisely on a surface during fabrication, and could then be cut or manipulated by an atomic force microscope (AFM) tip. Feng et al. (2002) reported that nanofibers were obtained by simply extruding a polyacrylonitrile (PAN) solution through an anodic alumina template into a solidifying solution. It was found that a water contact angle exceeding 170° was achieved by the surface of aligned PAN nanofibers without any surface treatment. It has also been reported by Ma and Zhang (1999) that a novel, highly porous structure, which was a three-dimensional interconnected fibrous network with a fiber diameter ranging from 50 to 500 nm, was created from biodegradable aliphatic polyesters. The nano-fibrous matrices were prepared from the polymer solutions by a procedure involving thermally induced gelation, solvent exchange and freeze-drying to mimic natural extracellular matrix architecture. Polymer nanofibers can also be formed by electrospinning. Shao et al. (2008) reported the formation of PAN nanofibers by electrospinning. The electrospun PAN nanofibers could be used as substrates for depositing the functional layer of zinc oxide (ZnO) on the PAN nanofiber surfaces by sol-gel technique. The functional carbon nanofibers were obtained by the carbonization of ZnO coated PAN nanofibers.

The utilization of electrostatic force to produce microdiameter fibers was first put forward by Anton Formhals’s series of patents published from 1934 to 1944. However, until the 1990s, electrospinning derived from ‘electrostatic spinning’ has been considered the primary technique for producing nanofibers as the interest in these fibers expanded. Since then, electrospinning has been adopted in the fabrication of various polymer nanofibers.

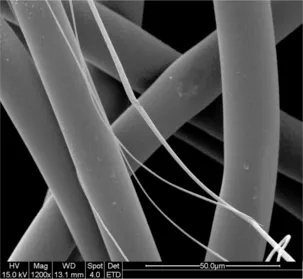

In terms of textile fibers, nanofibers (Ramakrishna et al., 2005; Brown and Stevens, 2007) are generally defined as one-dimensional flexible solid-state nanomaterials characterized by a diameter equal to or less than 0.1 μm (100 nm) and an aspect ratio greater than 100:1. However, this strict definition is impractical for textile processes; nanofibers are usually defined as fibers with a diameter of less than 1 μm (1000 nm) or less than 0.5 urn (500 nm). Figure 1.1 indicates the significant difference in diameter between normal polylactic acid (PLA) fibers and electrospun polylactic acid nanofibers. The normal fibers in Fig. 1.1 have diameters of about 20 μm, but the electrospun PLA nanofibers have diameters of about 200 nm.

1.1 SEM image of PLA fibers and nanofibers.

1.2 Principles of electrospinning

1.2.1 Electrospinning devices

Electrospinning has been most widely adopted to produce fibers with diameters ranging from a few nanometers to several micrometers, either in the form of solution electrospinning (S-ES) or melt electrospinning (M-ES). Basically, an electrospinning apparatus consists of the following four major components:

1. High-voltage power supply: A high-voltage power supply is needed to provide an electrostatic field for electrospinning. The supply needed could provide high voltage from a few thousand volts to a hundred thousand volts, depending on the materials being electrospun.The term ‘electrospinning’ comes from the use of electrostatic force to draw fibers.

2. Flow control pump: A flow control pump is usually used to adjust the flow rate of spinning fluid in order to produce the fiber with a controllable diameter. Flow rate affects the fiber diameter and productivity.

3. Spinneret: A spinneret is used to form small tubes for the polymer solution or melt to flow through. A spinneret can be arranged in different configurations depending on the formation forms of fibers.

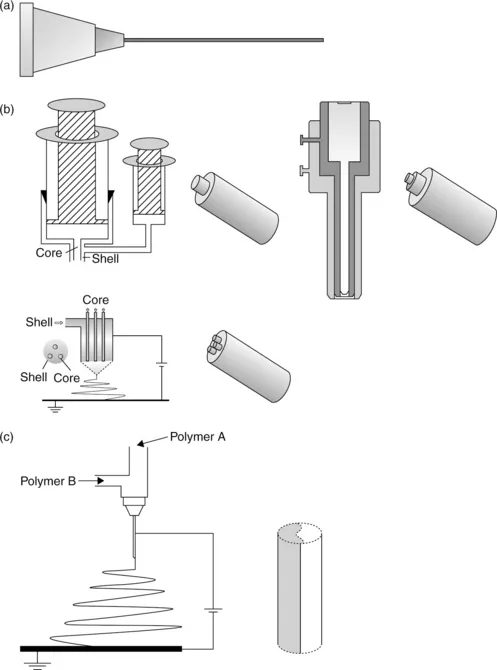

(a) Single spinneret: As shown in Fig. 1.2, different shapes of single spinneret can be developed either for the fabrication of electrospun pure fibers or for electrospinning component fibers depending on the configuration of the spinnerets.

1.2 Different shapes of single spinneret: (a) normal spinneret, (b) coaxial spinnerets and (c) side by side spinneret.

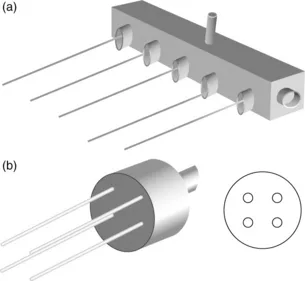

(b) Multispinnerets: Multispinnerets can be arranged either in linear array or in two-dimensional arrays and the number of nozzles can be made as required, as illustrated in Fig. 1.3. Multispinnerets are used to increase the productivity of the electrospinning.

1.3 Multispinnerets with different arrangements: (a) linear array and (b) two-dimensional array.

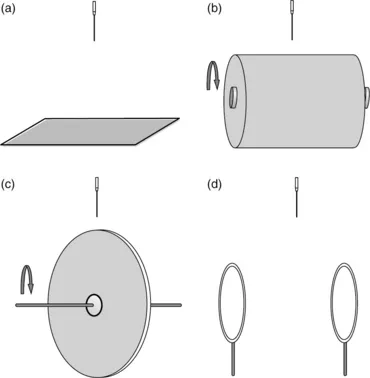

4. Collector: To obtain different fiber assemblies, a collector can be designedin various forms, as required. A plate, a rotating drum, a rotating disc,rings or any other shapes, as shown in Fig. 1.4, are not unusual.

1.4 Schematic diagram of main electrospinning collectors: (a) plate collector, (b) rotating drum collector, (c) disc collector and (d) ring collector placed in parallel.

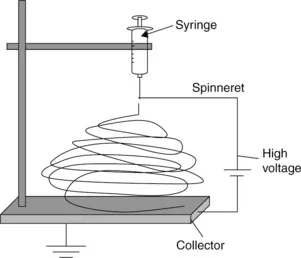

A typical schematic of the electrospinning process is presented in Fig. 1.5. The apparatus as well as the components can be set up and adjusted in accordance with the actual needs. With high-voltage potential applied, polymer solution or melt inside the spinneret is forced through a flow control pump to form a pendant drop at the tip of the spinneret. Free charges are induced into the polymer solution as a result of the applied high-voltage potential. In response to the applied electric field, these charged ions move toward the electrode of opposite polarity, transferring stretching forces generated by the electrical field to the polymer liquid. As the applied electric field increases, the hemispherical surface of the fluid at the tip of the spinneret is stretched and conic shape called Taylor cone is formed. When the applied high-voltage potential reaches a critical value, the electrostatic forces overcome the surface tension and a charged jet of the solution ejected from the tip of the Taylor cone is rapidly accelerated to the grounded collecting target. Due to instabilities in the jet, the charged jet undergoes violent whipping and elongation, allowing evaporation of solvent or cooling of melts to form solid fibers on the collector (Huang et al., 2003; Ramakrishna et al., 2005; Kulkarni et al., 2010; Brown and Stevens, 2007; Subbiah etal., 2005).

1.5 Schematic diagrams of electrospinning apparatus.

1.2.2 Fiber formation mechanism of electrospinning

The electrospinning pr...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Contributor contact details

- Woodhead Publishing Series in Textiles

- Part I: Types and processing

- Part II: Applications

- Index