- 450 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Primer on Flat Rolling

About this book

Primer on Flat Rolling is a fully revised second edition, and the outcome of over three decades of involvement with the rolling process. It is based on the author's yearly set of lectures, delivered to engineers and technologists working in the rolling metal industry. The essential and basic ideas involved in designing and analysis of the rolling process are presented.

The book discusses and illustrates in detail the three components of flat rolling: the mill, the rolled metal, and their interface. New processes are also covered; flexible rolling and accumulative roll-bonding. The last chapter contains problems, with solutions that illustrate the complexities of flat rolling.

New chapters include a study of hot rolling of aluminum, contributed by Prof. M. Wells; advanced applications of the finite element method, by Dr. Yuli Liu and by Dr. G. Krallics; roll design by Dr. J. B. Tiley and the history of the development of hot rolling mills, written by Mr. D. R. Adair and E. B. Intong.

Engineers, technologists and students can all use this book to aid their planning and analysis of flat rolling processes.

- Provides clear descriptions for engineers and technologists working in steel mills

- Evaluates the predictive capabilities of mathematical models

- Assignments and their solutions are included within the text

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Introduction

In this chapter, the topic of flat rolling of metals is introduced. The products of flat rolling, strips and plates, are defined in terms of their geometry; the ratio of their thickness to width is much less than unity. Strips are substantially thinner than plates. Rolling of strips and plates is generally referred to as flat rolling. The objectives of the process – that of reducing the thickness of the work piece, increasing its length and thereby changing its mechanical and metallurgical attributes – are stated in this introductory chapter. The temperatures at which the hot, warm and cold rolling processes are performed are defined. Each of the processes is presented and discussed in general terms. The equipment, the hot strip mill, mini-mills, Sendzimir mills, planetary mills and the cold rolling mill are shown and described, along with several mill configurations. The continuous casting process, as applied in the hot rolling industry, is also shown. New, recently developed equipment is described, as well. A selected list of books and publications, dealing with the theory of plasticity, plastic forming of metals and specifically the flat rolling process, is followed by some general conclusions.

Keywords

flat rolling; hot; warm and cold rolling; strips; plates; rolling mill types

1.1 The Flat Rolling Process

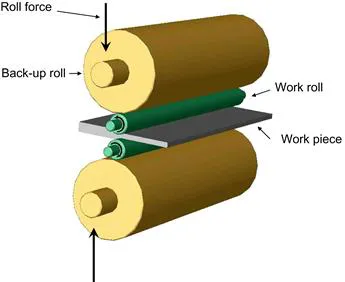

The mechanical objective of the flat rolling process is simple. It is to reduce the thickness of the work piece from the initial thickness to a pre-determined final thickness. This is accomplished on a rolling mill, in which two work rolls, rotating in opposite directions, draw the strip or plate to be rolled into the roll gap and force it through to the exit, causing the required reduction of the thickness. As these events progress, the material’s mechanical attributes change. These in turn cause changes to the metallurgical attributes of the metal, which, arguably are of more importance as far as the product is concerned. A schematic, three-dimensional diagram of the back-up rolls and the work rolls is shown in Figure 1.1 where a single-stand, four-high mill is depicted; this may be a single-stand roughing mill.

Figure 1.1 A schematic diagram of a single-stand, four-high set of rolls.

Figure 1.1 shows the back-up rolls, the much smaller work rolls, the strip being rolled and the roll separating forces acting on the journals of the back-up roll bearings, keeping the centre-to-centre distance of the bearings as constant as possible1. As will be demonstrated in Chapter 10, the energy requirements of the process may be decreased when small diameter work rolls are used. The drawback of that step is the reduced strength of the work roll which necessitates the use of the massive back-up rolls to minimize the deflections of the work roll.

1.1.1 Hot, Cold and Warm Rolling

While the rolling process may be performed at temperatures above half of the melting point of the metal, termed hot rolling, or below that temperature, in which case one deals with cold rolling, the division into these two categories should not be considered as being cast in stone. There is a temperature range, beginning below and ending above the dividing line between hot and cold rolling, within which the process is termed warm rolling and in some specific instances and for some materials this is the preferred process to follow. These processes lead to mechanical and metallurgical changes of the attributes of the work piece, which are not possible to achieve in either the cold or the hot flat rolling regimes.

1.2 The Hot Rolling Process

Hot rolling of metals is usually carried out in an integrated steel mill, on a “Hot Strip Mill”, or since some changes were introduced in the last couple of decades, on mini-mills2. Both have advantages and disadvantages, of course, such as capital costs, flexibility, quality of the product and danger to the environment.

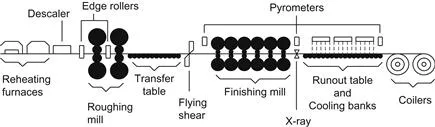

A schematic diagram of a traditional hot strip mill is depicted in Figure 1.2, showing the major components.

Figure 1.2 The schematic diagram of a traditional hot strip mill.

There are several basic components in the traditional hot strip rolling mill. In what follows, these are discussed briefly3.

1.2.1 Reheating Furnace

The reheating furnace constitutes the first stop of the slab after its delivery from the slab yard. The slab is heated up to 1200–1250°C in the furnace to remove the cast dendrite structures and dissolve most of the alloying elements. The decisions to be made in running the reheat furnace in an optimal fashion concern the temperature and the environment within. If the temperature is higher than necessary, more chemical components will enter into solid solution but the costs associated with the operation become very high and the thickness of the layer of the primary scale will grow. If the temperature is too low, not all alloying elements will enter into solid solution, affecting the metallurgical development of the product, and the likelihood of hard precipitates remaining in the metal increases. As well, thinner layers of scale will form, a fairly significant advantage. A judicial compromise is necessary here and is usually based on financial consideration. The cost savings associated with a one-degree reduction of the temperature within the furnace can be calculated without too many difficulties; the changes to the formation of solid solutions may be estimated but the annual savings may well be significant.

Primary scales of several millimetres thickness form on the slab’s surface in the reheat furnace. The thickness of the scale may be reduced by providing a protective environment within the furnace, albeit at some increased cost. As the furnace doors open and the hot slab slides down on the skids to the conveyor table, the instant chilling, caused by the water-cooled skids, causes marks that are often noticeable on the finished product. As well, fast cooling of the surfaces and especially of the edges is also immediately noticeable, indicating a non-uniform distribution of the temperature within the slab and leading to possibly non-homogeneous dimensional, mechanical and metallurgical attributes.

1.2.2 Rough Rolling

Before the rolling process begins, the scale is removed by a high-pressure water spray and/or scale breakers. The slab is then rolled in the roughing stands in which the thickness of the slab is reduced from approximately 200–300 mm to about 50 mm in several passes, typically four or five. The speeds in the rougher vary from about 1 m/s to about 5 m/s. In the roughing process the width increases in each pass and is controlled by vertical edge rollers. The vertical edgers compress and deform the slab somewhat, causing some thickening which is corrected in the subsequent passes. A large variety of roughing mill configurations is possible, from single-stand reversing mills to multi-stand, one-directional mills, referred to as roughing trains. These usually have a scale breaker as the first stand where the mill deforms the slab sufficiently just to loosen the scale, which is then removed by the high-pressure water jets. Roughing scale breakers are usually vertical edgers, capable of reducing the width of the slab by up to 5–10 cm and causing stresses at the steel surface-scale layer interface which then separate the scales. Roll diameters are near 1000 mm. The rolls are usually made of cast steel or tool steel4. Roughing stands are either of the two- or four-high configurations. At the end of the rough rolling process, the strip is sent to the finishing mill along the transfer table where it is referred to as the “transfer bar”. The temperature of the slab in the roughing stands is high enough so that the transfer bar is fully recrystallized, containing strain free, equiaxed grains. In general, though, the grain structure at the end of the rough rolling process seems to have little influence on the structure by the time the strip has passed through several stands of the finishing mill.

1.2.3 Coil Box

Not shown in Figure 1.2 is a device – an invention by the Steel Company of Canada and first installed in the early 1970s in Stelco’s Hilton Works – called the coil box5, placed between the roughing mill and the finishing train, in place of the transfer table. Since that time, several integrated steel companies have installed the coil box in their hot strip mills. A photograph of the coil box is shown in Figure 1.3.

Figure 1.3 The coil box. Source: Courtesy The Steel Company of Canada.

When the words “Coil Box” are entered into Google6, a plethora of information is found, in...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Dedication

- Preface to the Second Edition

- Preface to the First Edition

- Contributors

- Acknowledgements

- 1. Introduction

- 2. History of Hot Strip Mills

- 3. Roll Design

- 4. Flat Rolling – A General Discussion

- 5. Mathematical and Physical Modelling of the Flat Rolling Process

- 6. An Advanced Finite Element Model of the Flat, Cold Rolling Process

- 7. Flat Rolling – Simulation and Reduction of Local Buckles in Cold Rolling

- 8. Material Attributes

- 9. Tribology

- 10. Applications and Sensitivity Studies

- 11. Hot Rolling of Aluminium

- 12. Temper Rolling

- 13. Severe Plastic Deformation – Accumulative Roll Bonding

- 14. Roll Bonding

- 15. Flexible Rolling

- 16. Problems and Solutions

- Appendix

- References

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Primer on Flat Rolling by John G. Lenard in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Materials Science. We have over one million books available in our catalogue for you to explore.