- 416 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

Braided fabrics are made by interlacing yarns or strips of fabric. Braiding produces a wide range of structures for technical textile applications from medical sutures to cables for anchoring ships. Written by one of the world's leading experts in the field, the book reviews the basic principles, design and processes used in braiding. The book also discusses specialised braiding techniques such as spiral braiding and lace technology.

- Provides a solid foundation in the fundamentals of braiding design, processes and machinery

- Covers the patterning of braided products and the structural and colour design of both flat and tubular braids

- Reviews maypole braiding machines and mechanics

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Introduction: the main types of braided structure using maypole braiding technology

Abstract

In this chapter the main principles and methodologies for producing braided structures are introduced. The basics and the working principles of the most popular braiding machines are described in the section entitled Maypole Braiding. The less common braiding machines, such as those based on spiral braiding, lace braiding, bobbinet and Cartesian 3D braiding approaches, are also presented, together with a short explanation of their advantages and differences.

Keywords

Braiding

Machines

Products

Classification

Principle

1.1 Introduction

Braiding is a process of interlacing three or more threads diagonally to the product axis (parallel to the longest dimension of the resulting product) in order to obtain a thicker, wider or stronger product or in order to cover (overbraid) some profile. Braids can be linear products (ropes), curved or plane shell or solid structures (one, two or three-dimensional fabrics) with constant or variable cross-section, and of closed or open appearance.

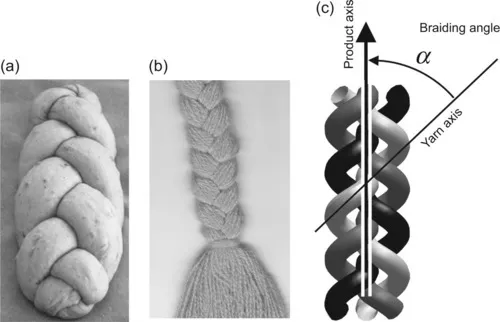

Interlacing diagonally means that the yarns make an angle α with the product axis, which can be between 1° and 89° but is usually in the range of 30°–80° (Fig. 1.1c). This angle is called the braiding angle and is the most important geometrical parameter of braided structures.

Figure 1.1 Braided cake (a), lace (b) and idealized representation (c).

The definition of what constitutes a one-, two- or three-dimensional fabric is not straightforward (Büsgen, 1993; Schneider, 2000; Hearle and Chen, 2013). The use of any dimension in such a classification requires information about the scale in which this term is used – micro-, meso-, or macro-scale – or equivalently, in textile terminology, fibre, yarn or product level.

From an engineering point of view, each braided rope or shoe lace can be classified as a one-dimensional product, because the length of each is significantly greater than the cross-section. If, however, we consider yarn interlacement, each rope is a three-dimensional product because of its curved outer structure. Hence, the definition of braids employed above.

1.2 Maypole braiding

The classical and mainly used braiding machines are known as maypole braiding machines. This name will always be used where these machines have to be distinguished from the other (spiral, lace) braiding machines. This section introduces the working principle of these machines, the types of structures and machines and their modifications in order to give an overview of the technology. The topics from this section are presented with more details in several chapters in the book.

1.2.1 Basic principle

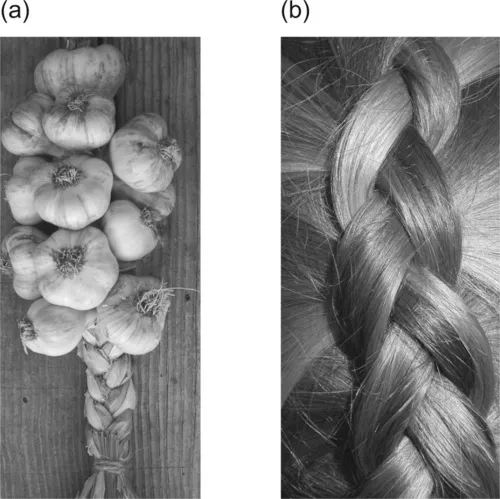

In its basic form, braiding has been used for many years in a wide range of application areas, including the braiding of yarns, flowers, hair, etc. (Fig. 1.1), and the braiding process allows for the addition or replacement of yarns during each step (Fig. 1.2). The application areas for braided products are broad, ranging from the braiding of chirurgical sutures and other medical items, to such products as electric cables, ropes, laces and, at the largest scale, the huge ropes and tubes used in the marine oilfield sector. Also, a growing area of use of braids is in the production of fibre-reinforced composites.

Figure 1.2 The braiding allows adding new elements to the braid at each step: (a) garlic and (b) hair.

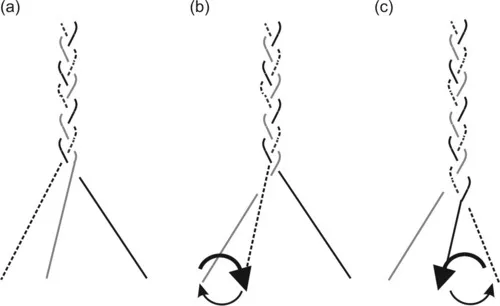

All the products discussed above are manufactured in the same way, that is, by the interlacing of yarns at an angle of about 40°–60° to the main product axis. Figure 1.3 demonstrates the principle of hand braiding for a simple braid of three yarns (braided pigtail). The interlacement can be described in two steps:

Figure 1.3 Principle of hand braiding with three yarns. (a) Initial configuration; (b) first step: interlacing the left yarn over the middle one; (c) second step: interlacing the right yarn over the new middle yarn.

• interlace the left two yarns, where the outer left yarn goes over the next one (Fig. 1.3b);

• interlace the right two yarns, where the right yarn goes over the left next nearest yarn (Fig. 1.3c), and so on.

1.2.2 Flat braiding

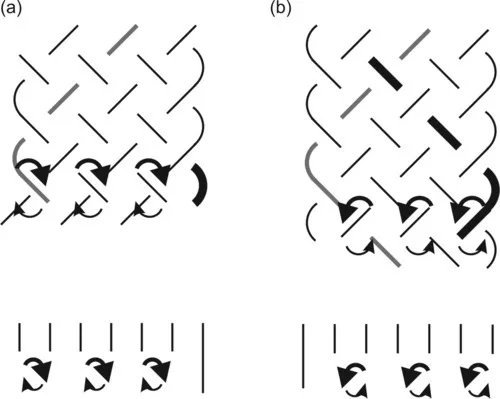

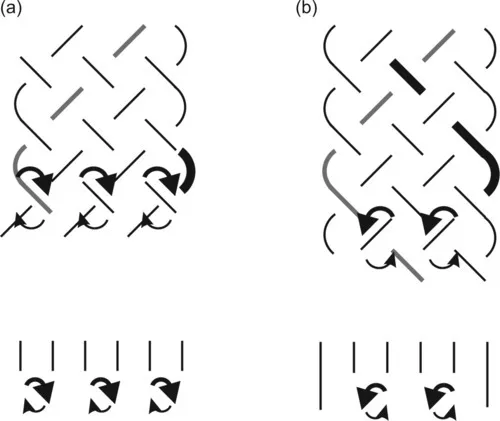

The above described process can be extended to more yarns, for examples 5, 7, etc. as demonstrated in Fig. 1.4. In this case, at the first step all left pairs have to be interlaced, so that the left goes over the right, and in the second step, all right pairs have to be interlaced, so that the right yarn goes over the left.

Figure 1.4 Hand braiding of odd (here seven) yarns. (a) Interlace each left yarn over each right in the pairs; (b) interlace each right yarn over the left one, but shifting the starting position on one yarn.

The same principles are implemented on certain machines for braiding and the resulting product is a flat cross-sectioned braid, known as “flat braid”. Flat braiding is possible for both odd and even numbers of yarns. Figure 1.5 demonstrates the sequence in the case of six yarns: at every second step, yarns from both the left and right sides stay and wait, while when using an odd number of yarns, only one yarn per cycle stays unused during the interlacement.

Figure 1.5 Hand braiding of even (here six) yarns. (a) Interlace each left yarn over each right in the pairs; (b) interlace each right yarn over the left one, but shifting the starting position on on...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright page

- Woodhead Publishing Series in Textiles

- Preface

- Dedication

- Acknowledgements

- 1: Introduction: the main types of braided structure using maypole braiding technology

- Part One: Patterning and design of braided structures manufactured using maypole braiding technology

- Part Two: Maypole braiding machines and mechanics

- Part Three: Specialist braided structures using maypole braiding technology

- Part Four: Computer assisted design (CAD), other software and productivity calculations for braiding

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Braiding Technology for Textiles by Yordan Kyosev in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Materials Science. We have over one million books available in our catalogue for you to explore.